- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Chongqing, China

-

Brand Name:

-

VPURE

-

Voltage:

-

220~415V

-

Power:

-

As Required

-

Dimension(L*W*H):

-

As Required

-

Weight:

-

100000 kg

-

Application:

-

Used Motor Oil Recycling Machines

-

Function:

-

Diesel Distillation Machine

-

Raw material:

-

Waste Lube Oil

-

End product:

-

80-93% Diesel

-

Capacity:

-

2-50TPD

-

Advantages:

-

Fully Continuous

-

Structure:

-

Distillation Column

-

Technology:

-

Exclusive Desulfurization

-

Environmental protection:

-

Environmental Protection Standard

-

Working temperature:

-

30~450 ℃

Quick Details

-

Applicable Industries:

-

used engine oil refining machine

-

Marketing Type:

-

New Product 2023

-

Flow:

-

2-50 TPD

-

Place of Origin:

-

Chongqing, China

-

Brand Name:

-

VPURE

-

Voltage:

-

220~415V

-

Power:

-

As Required

-

Dimension(L*W*H):

-

As Required

-

Weight:

-

100000 kg

-

Application:

-

Used Motor Oil Recycling Machines

-

Function:

-

Diesel Distillation Machine

-

Raw material:

-

Waste Lube Oil

-

End product:

-

80-93% Diesel

-

Capacity:

-

2-50TPD

-

Advantages:

-

Fully Continuous

-

Structure:

-

Distillation Column

-

Technology:

-

Exclusive Desulfurization

-

Environmental protection:

-

Environmental Protection Standard

-

Working temperature:

-

30~450 ℃

Product Descriptions

What is A Waste Oil to Diesel Plant?

A waste oil to diesel plant is an industrial facility designed to convert waste oils into diesel fuel through a process called pyrolysis distillation. This process involves heating the waste oil to high temperatures in the absence of oxygen, causing it to break down into smaller molecules that can be further refined into diesel fuel. The process typically involves pre-treating the waste oil to remove impurities, heating the oil in a reactor vessel to a specific temperature, and then cooling and condensing the resulting vapors to produce a liquid fuel.

Waste oil to diesel plants are considered a valuable source of renewable energy, as they provide an alternative to traditional fossil fuels. By converting waste oil into diesel fuel, these plants help to reduce the amount of waste oil that would otherwise be sent to landfills or improperly disposed of. Various designs of waste oil to diesel plants are available, ranging from small-scale mobile units to large, fully automated industrial facilities. The specific design and capacity of a plant will depend on factors such as the type and amount of waste oil being processed, as well as the desired output of diesel fuel.

What do we do

1. Turnkey solution for Waste Oil Refinery, Base Oil Extraction Plant, Lube Oil Blending Plant, and Fuel Oil Desulfurization Plant.

2.

Engineering service for customized petrochemical project(i.e. distillation, extraction, desulfurization and so on.)

3. One-stop-service for additives, catalysts, absorbents, laboratory instruments, tanks, pumps and other parts & parts of our petrochemical plant.

Applications

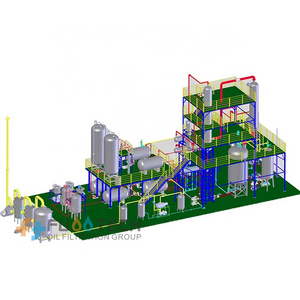

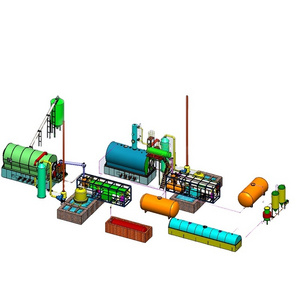

PPGT-DF Waste Oil Distillation Plant

is designed to crack the long chain hydrocarbons of waste motor oil into valueable diesel fuel and some byproducts such as light gas oil, light hydrocarbons, water and asphaltene sludge. With PurePath exclusive

fractionating and ultrasonic desulfuring technologies

, the diesel which is produced by our distillation plant is able to meet

Euro-V related standards

.

PPGT-DF Waste Oil Distillation Plant is able to convent different types waste oil feedstock into diesel fuel and other valuable byproducts, such as

waste motor oil, waste gear oil, waste crackcase oil, waste hydraulic oil, tire/plastic pyrolysis oil, slop oil etc.

. PPGT-DF series help relieving energy crisis as well as creating profits with a reasonable operation cost.

Working Principle

PPGT-DF Waste Oil Distillation Plant

has adopted PurePath unique engineering designs which may be consisted by following systems:

1. Dehydration & Sendimentation System;

2. LGO Stripping System;

3. Fractionating & Reflux System;

4. Heaters & Heat Exchangers;

5. Diesel Polishing System;

5. Diesel Polishing System;

6. PLC/Scada Control System.

Product Specifications

|

Model No.

|

PPGT-DF-1

|

PPGT-DF-2

|

PPGT-DF-3

|

PPGT-DF-4

|

PPGT-DF-5

|

PPGT-DF-6

|

PPGT-DF-7

|

||||||

|

Capacity

|

2 TPD

|

5 TPD

|

10 TPD

|

15 TPD

|

20 TPD

|

30 TPD

|

50 TPD

|

||||||

|

Heating Power

|

17KGS LPG/20KGS FUEL OIL/230KWH/PER TON OF WASTE OIL

|

|

|

|

|

|

|

||||||

|

Power Consumption

|

25KWH PER TONS OF WASTE OIL

|

|

|

|

|

|

|

||||||

|

Vacuum Degree

|

Atoms. pressure

|

|

|

|

|

|

|

||||||

|

Heating Method

|

Fuel Oil/Natural Gas/LPG/Electricity

|

|

|

|

|

|

|

||||||

|

Heating Temp.

|

30-420℃

|

|

|

|

|

|

|

||||||

|

Voltage

|

220/380/415V 50/60HZ

|

|

|

|

|

|

|

||||||

|

Noise

|

≤60dB

|

|

|

|

|

|

|

||||||

Our Services

Reliability Throughout the Whole Lifetime!

PurePath is committed to providing our customer with exclusive turnkey solution and extraordinary services all over the pre-sales, manaufacturing, delivery, installation and after sales process to make sure that each of our customer will be satisfied to our services.

Free Consulting Service

PurePath provides our client with free project consulting service such as project establishment; feasibility study; market research; factory layout; emission control; consumables to making sure the successful start-up of whole project.

Free Engineering Service

PurePath has been providing each of our potential customer with Free Engineering Service during pre-sale stage to enabling every project that we are involvded will be the best to suit our client's requirements.

After Sale Service

PurePath is dedicated to prodiving our clients with the most satisfying after sale service in full equipment lifecycle with only cost price for replaced parts and swift online support for free of charge after the equipment we produced is out of warranty period.

Hot Searches