- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380 V or other require

-

Power:

-

6KW

-

Dimension(L*W*H):

-

2520*1080*1800mm.

-

Weight:

-

1800 kg

-

Suitable Paper Weight:

-

140-350gsm

-

Rated Productivity:

-

100-110 pcs/min

-

GW/NW:

-

1800KGS/1700KGS

-

Package Size:

-

2520*1080*1800mm

-

Cup Side Welding:

-

Copper Heater or Ultrasonic heater

-

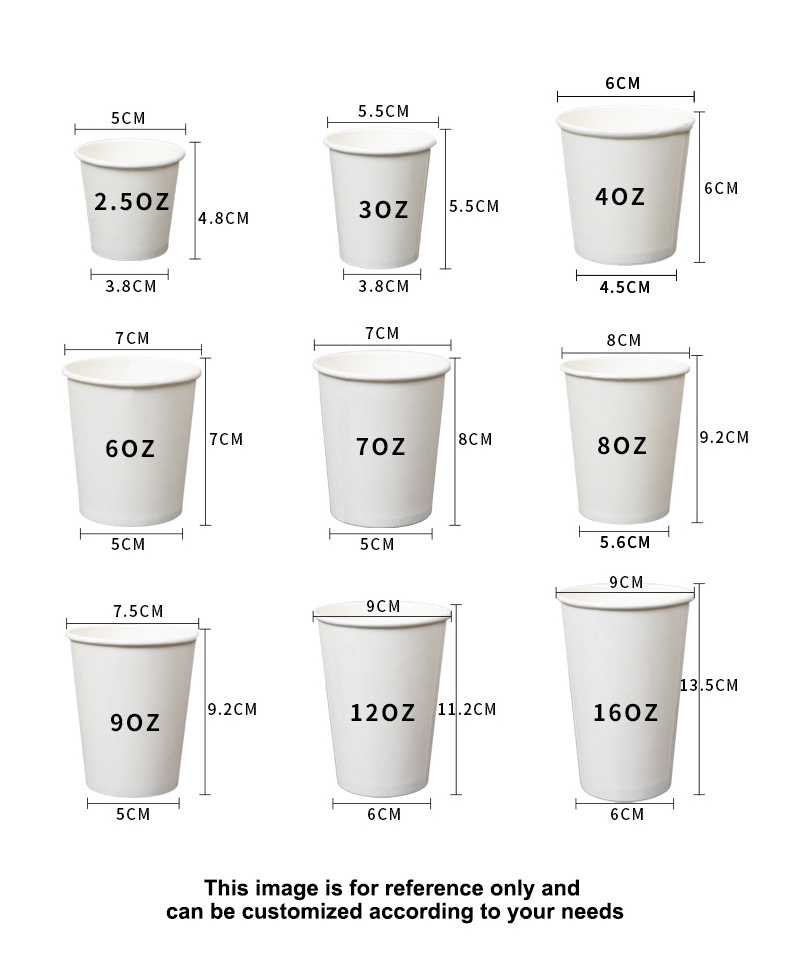

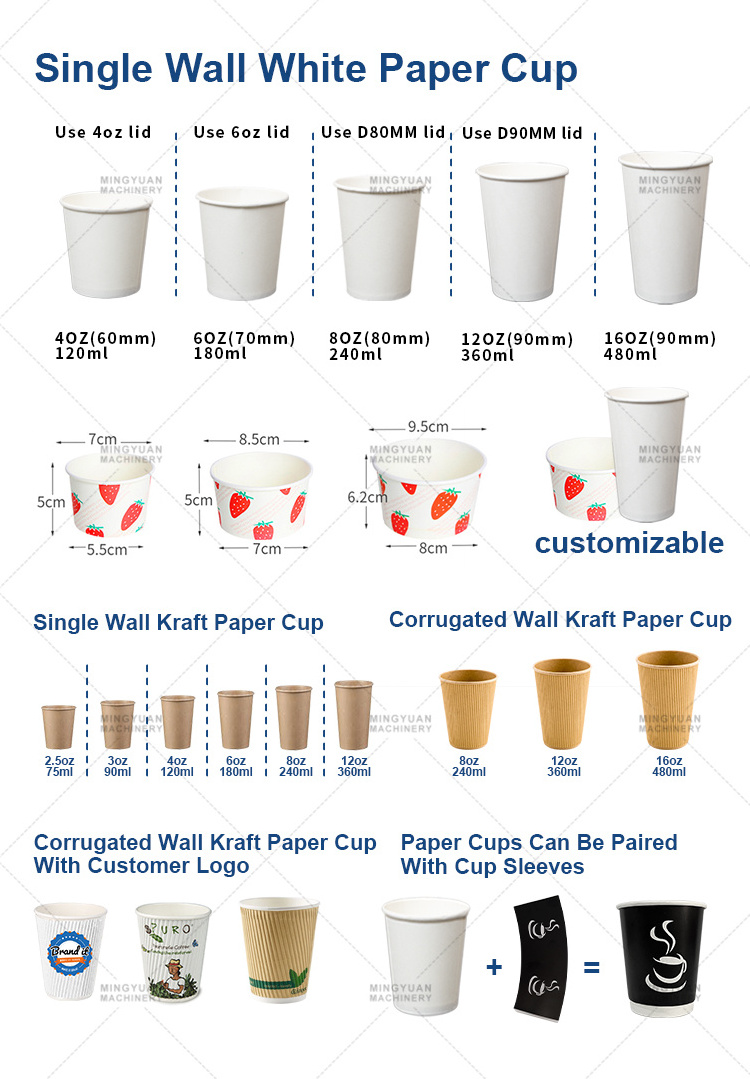

Paper Cup Size:

-

2 ~16 OZ (50ml~330ml Mould exchangeable)

-

Raw Material:

-

One or Two side PE coated Paper

-

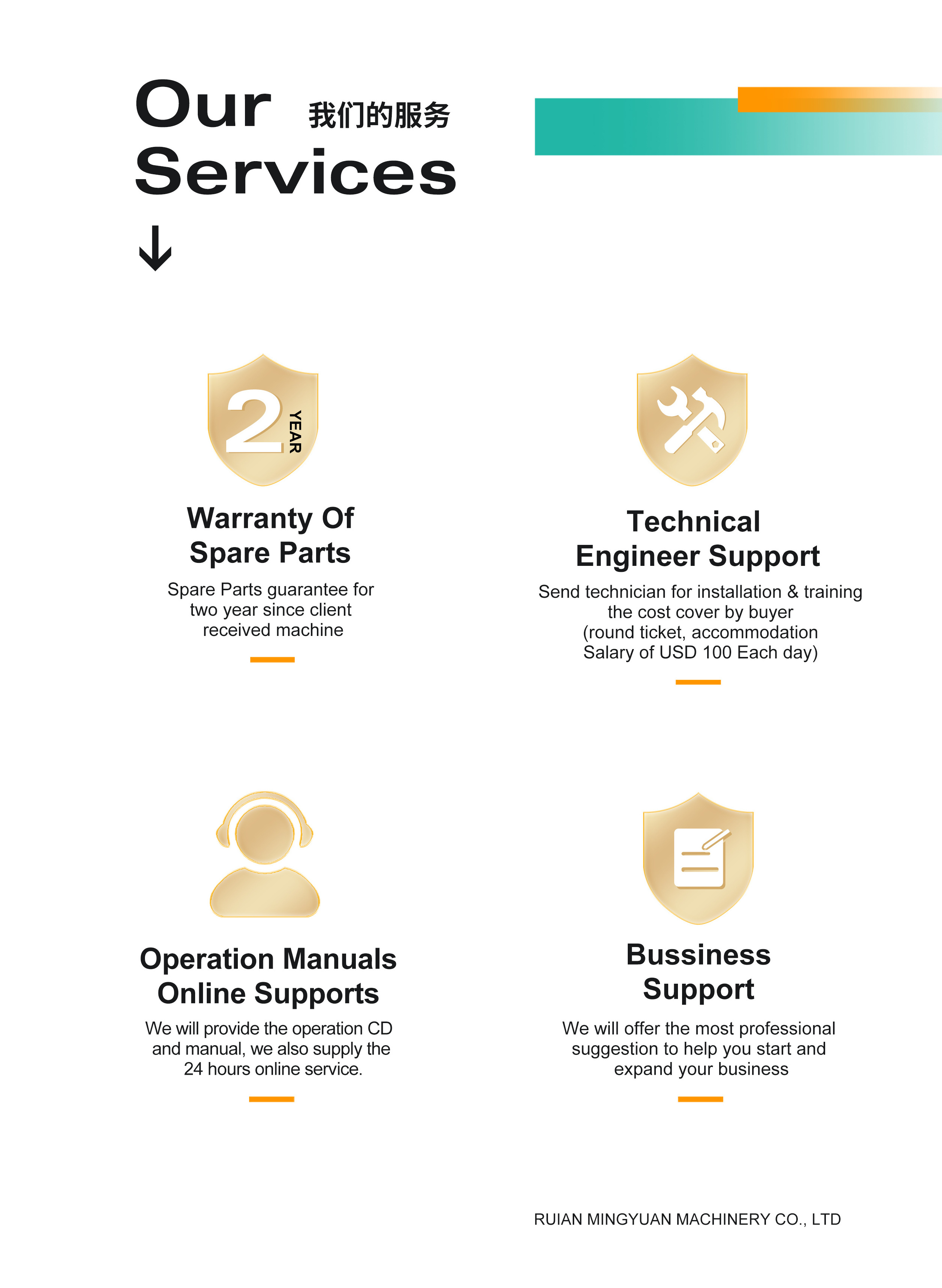

After-sales Service Provided:

-

Engineers available to service machinery overseas

Quick Details

-

Production Capacity:

-

100-110 pcs/min

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

MINGYUAN

-

Voltage:

-

220V/380 V or other require

-

Power:

-

6KW

-

Dimension(L*W*H):

-

2520*1080*1800mm.

-

Weight:

-

1800 kg

-

Suitable Paper Weight:

-

140-350gsm

-

Rated Productivity:

-

100-110 pcs/min

-

GW/NW:

-

1800KGS/1700KGS

-

Package Size:

-

2520*1080*1800mm

-

Cup Side Welding:

-

Copper Heater or Ultrasonic heater

-

Paper Cup Size:

-

2 ~16 OZ (50ml~330ml Mould exchangeable)

-

Raw Material:

-

One or Two side PE coated Paper

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

Data for machines

|

Model

|

High Speed Single Plate Open Cam Paper Cup Machine MYC-OCM12

|

|

|

|

||||

|

Paper Cup Size

|

2 ~16 OZ (Mould exchangeable, Max Cup Height:135mm , Max Bottom width :70mm

|

|

|

|

||||

|

Rated Speed

|

100-110pcs/min ( Speed affected by cup size, paper quality & thickness), 9OZ, 280GSM paper cup Stable running speed 100-110 pcs each min

|

|

|

|

||||

|

Raw Material

|

One or Two side PE coated Paper(Popular for Hot and Cold drink Cups)

|

|

|

|

||||

|

Suitable paper weight

|

140-350gsm

|

|

|

|

||||

|

Power Source

|

50/60HZ, 380V/220V ( better use 380V, 3 Phase ) or special Power requirement

|

|

|

|

||||

|

Total Power

|

6KW

|

|

|

|

||||

|

Total Weight

|

GW/NW: 1800KGS/1700KGS

|

|

|

|

||||

|

Pack Size(LWH)

|

2100*970*1700mm(Machine Packing Size)

1250*860*1860MM(Counting Machine Packing Size) |

|

|

|

||||

|

Working Air Source

|

Air pressure:0.4Mpa:

Air Out-put:0.6m³/minute Need to buy Air Compressor(by user) |

|

|

|

||||

|

Cup Side Welding

|

Ultrasonic heater

|

|

|

|

||||

|

Cup Bottom Heating

|

1side PE paper by heater knurling;

2side PE paper by cool device (circle water) knurling |

|

|

|

||||

|

Cup Bottom Knurling

|

Heater Knurling (if use single PE coated paper)

|

|

|

|

||||

|

OEM ( Show Client Company Name in Machine Panel ) is welcome in our factory

|

|

|

|

|

||||

Product details

Vaccum Suction Generator

Prevent wet air with water from entering solenoid valve, longer service life more stable and better.

Metal Rod Accessories Thickness Upgrade

New design is durable better quality is not easy to be broken in long time running.

12 Pcs Of Sensor

lt can detect the full working process of the machine like paper less paper stuck,paper tube blocking, hot air blowing bottom paper feeding and cup passing by errors. lt will send alarm and ensure machine inside spare parts less collision issues,and run more stable.

Metal Pipes

It is for the connection of hot air blowing heater , durable and high temperature resistance.

12 PCS Honeywell Relay

Best lmported US brand relay ,best quality and longer service life

Oil Lubrication and Circulation

The whole machine adopts automatic oil lubrication system( oil circulation system is including oil motor, filter, copper pipe )which makes all gear moving parts working at high speed much more smoothly and greatly improve the service life of spare parts

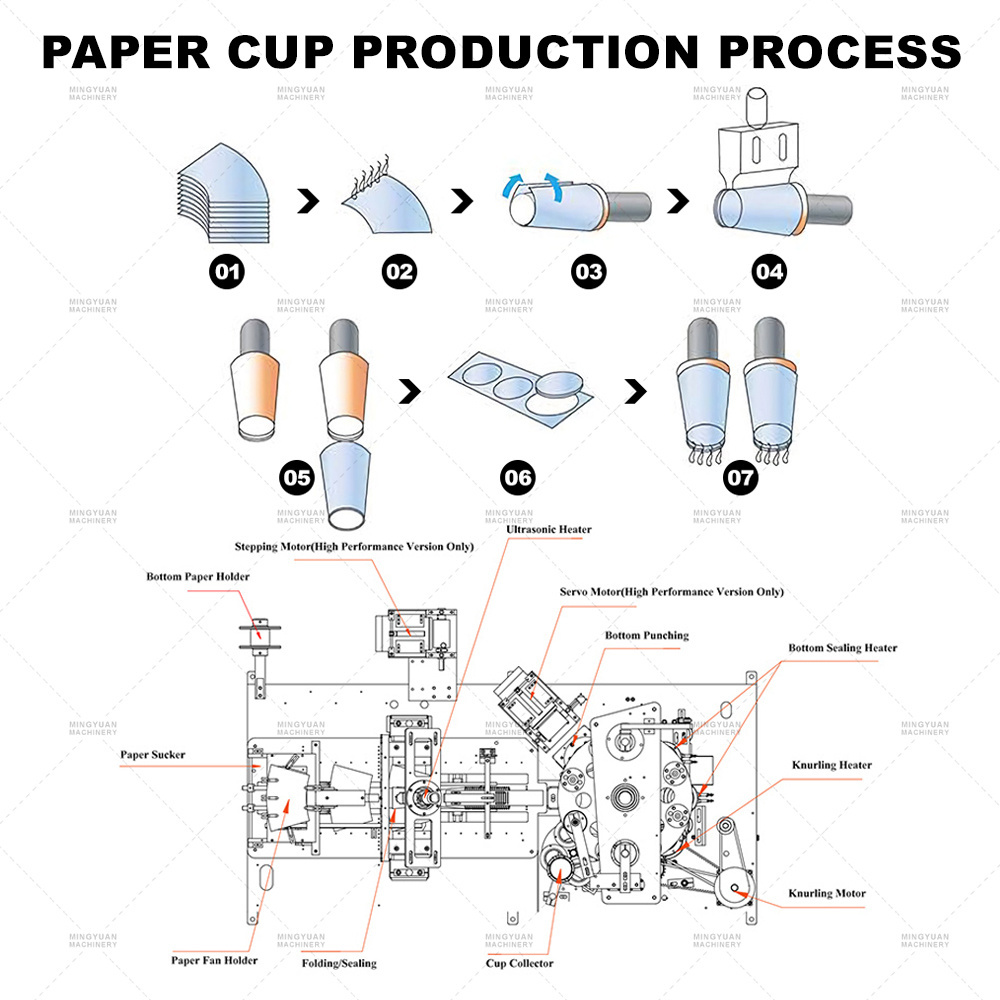

Production Flow

Company History

About Us

Packaging shipping

FAQ

Q1. Are you trading company or manufacturer?

A:we are one of the leading manufacturer of the paper cup machine, Plastic lid machine, paper plate machine etc paper product machinery in China.

Q2. How will the machine be repaired if there are faults, and what is the warranty?

A:Our engineer team will send the operation video to guide you to solve the problem .if the spare parts is broken in the warranty period, we will send you the new replacement parts for free

Q3. What is the delivery time after the order ?

A:We have only half finished machine (no mould) in stock.The mould design is customized as each customer requirement The mould production costs 20 days,10 days for the installation.The delivery time is 30-35 days after the deposit payment .

A:we are one of the leading manufacturer of the paper cup machine, Plastic lid machine, paper plate machine etc paper product machinery in China.

Q2. How will the machine be repaired if there are faults, and what is the warranty?

A:Our engineer team will send the operation video to guide you to solve the problem .if the spare parts is broken in the warranty period, we will send you the new replacement parts for free

Q3. What is the delivery time after the order ?

A:We have only half finished machine (no mould) in stock.The mould design is customized as each customer requirement The mould production costs 20 days,10 days for the installation.The delivery time is 30-35 days after the deposit payment .

Q4.How can I install the machine and get training services in my country?

A:The machine will be finished installation and tested running perfectly before the delivery . You will get the complete machine which is finished installation. We will provide the full operation and training Videos to guide you to run the machine Anyone can install the machine and operate it easily.

Q5. What terms of payment you usually use?

A:T/T 30% deposit and 70% before machine loading, Western Union, L/C at sight.

A:The machine will be finished installation and tested running perfectly before the delivery . You will get the complete machine which is finished installation. We will provide the full operation and training Videos to guide you to run the machine Anyone can install the machine and operate it easily.

Q5. What terms of payment you usually use?

A:T/T 30% deposit and 70% before machine loading, Western Union, L/C at sight.

Hot Searches