- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

7 swords

-

Processing Type:

-

Cnc Turning Cnc Milling

-

Keyword:

-

Rack And Pinion For Cnc Parts

-

Our Service:

-

24 hours online

-

Process:

-

cnc turning and milling

-

Length:

-

Customized Length

-

Application:

-

Machinery

-

Certificate:

-

ISO9001

-

Surface treatment:

-

Polished

-

After Warranty Service:

-

No service

Quick Details

-

Weight (KG):

-

1

-

Place of Origin:

-

Guangdong, China

-

Model Number:

-

Customize

-

Brand Name:

-

7 swords

-

Processing Type:

-

Cnc Turning Cnc Milling

-

Keyword:

-

Rack And Pinion For Cnc Parts

-

Our Service:

-

24 hours online

-

Process:

-

cnc turning and milling

-

Length:

-

Customized Length

-

Application:

-

Machinery

-

Certificate:

-

ISO9001

-

Surface treatment:

-

Polished

-

After Warranty Service:

-

No service

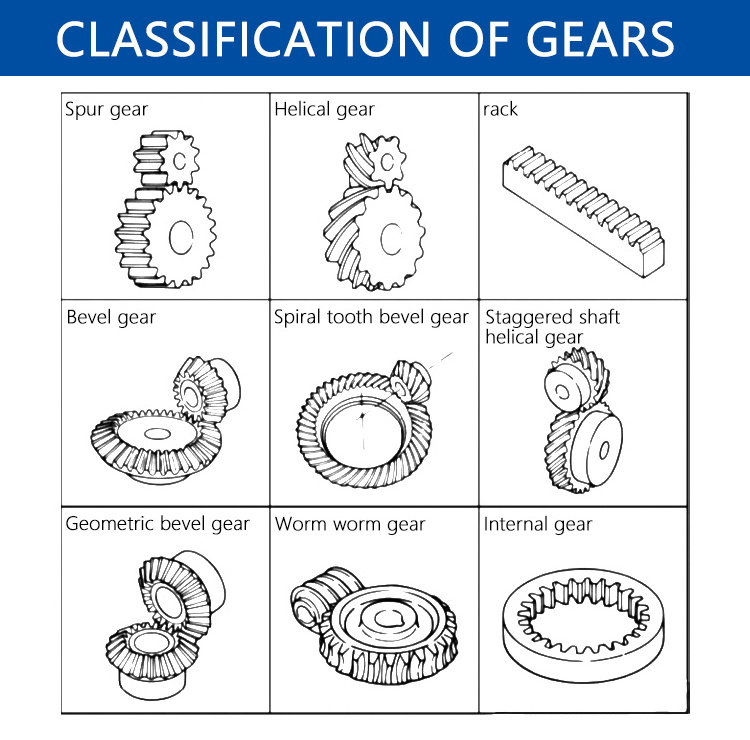

CLASSIFICATION OF GEARS

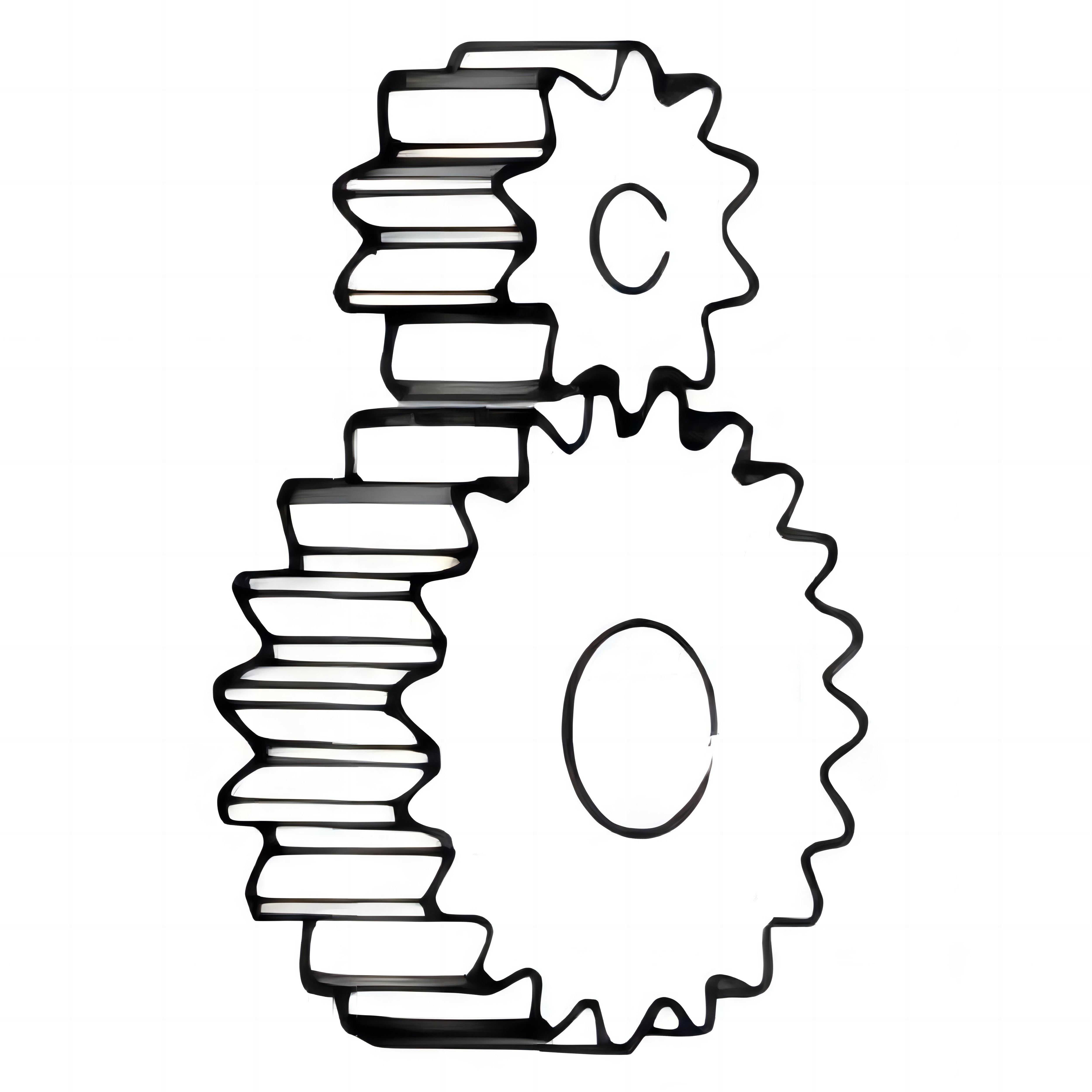

Spur gear

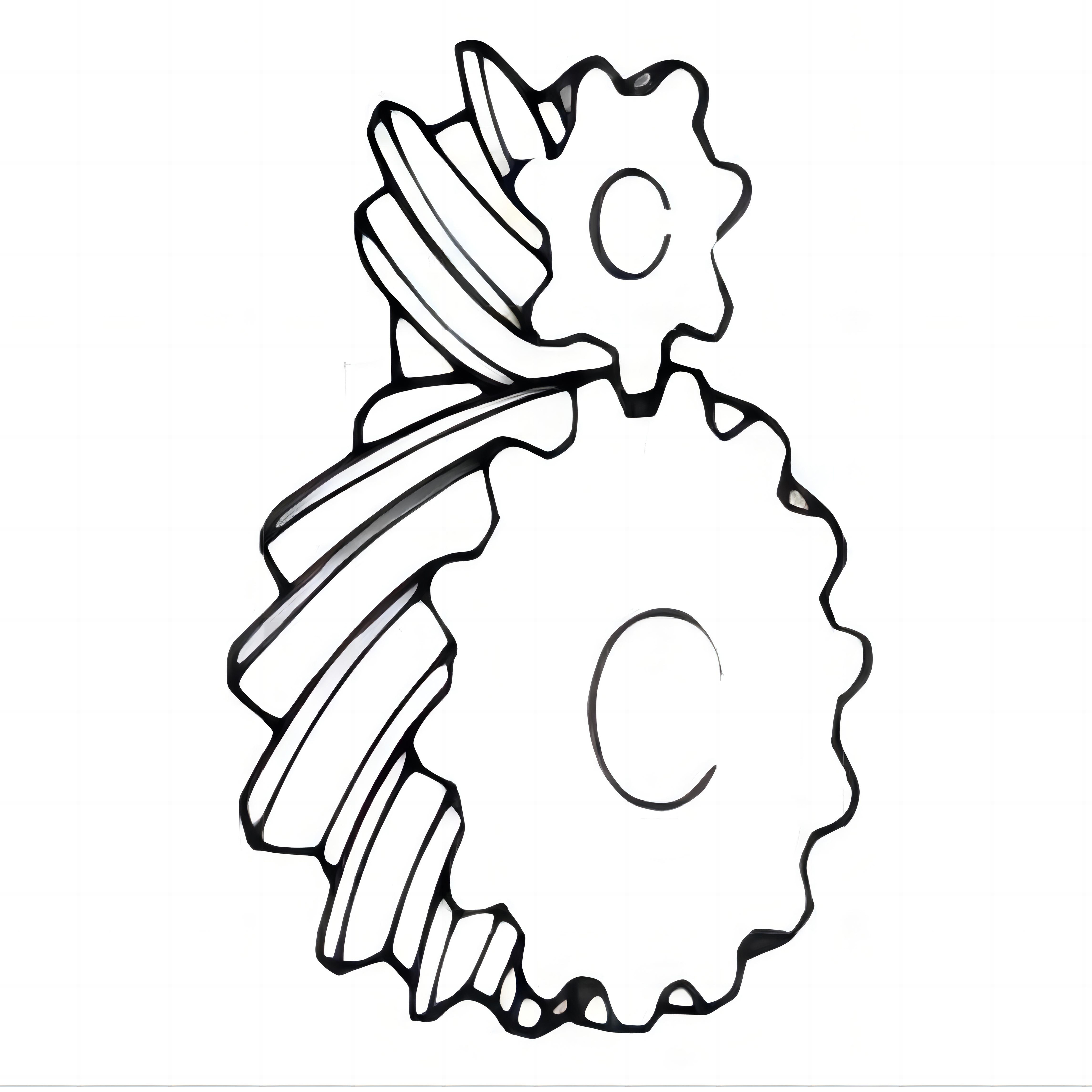

Helical gear

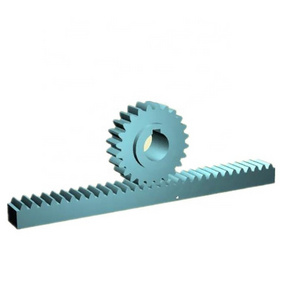

Rack

Bevel gear

Spiral tooth bevel gear

Staggered shafthelical gear

Geometric bevel gear

Worm worm gear

Internal gear

OUR SERVICE

|

Tooth Profile

|

Spur Gears, Helical Gears, Bevel Gears

|

|

|

|

|

Module

|

M0.5, M0.8, M1.0, M1.5,M2.0,M2.5,M3.0...etc

|

|

|

|

|

Teeth Quantity

|

10-150 teeth or customized

|

|

|

|

|

Inner Bore

|

2-200mm or customized

|

|

|

|

|

Pressure Angle

|

20 Degree

|

|

|

|

|

Direction

|

Left hand or right hand

|

|

|

|

|

Teeth Width

|

Customized

|

|

|

|

|

Total Thickness

|

Customized

|

|

|

|

|

Heat Treatment

|

Gear Teeth Induction Quenching

|

|

|

|

|

Application Industry

|

|

|

|

Automotive

|

Power Steering Rack and Pinion Assembly

Steering Gear Rack and Pinion Unit

Steering Rack and Pinion Kit

Rack and Pinion Steering Gear Box

|

|

|

Industrial Machinery

|

Linear Motion Rack and Pinion System

Rotary Motion Rack and Pinion Drive

Actuator Rack and Pinion Assembly

Positioning System with Rack and Pinion

|

|

|

Material Handling

|

Crane Hoist Rack and Pinion System

Scissor Lift Rack and Pinion Drive

Cargo Elevator Rack and Pinion Assembly

Automated Storage and Retrieval System (ASRS) Rack and Pinion Drive

|

|

|

Construction

|

Scaffolding Rack and Pinion System

Elevator Rack and Pinion Drive

Bridge Formwork Rack and Pinion Assembly

Mast Climbing Work Platform Rack and Pinion Drive

|

|

|

Robotics

|

Robotic Arm Rack and Pinion Drive

Linear Actuator with Rack and Pinion System

CNC Machine Tool Rack and Pinion Drive

Gantry Robot Rack and Pinion Assembly

|

|

|

Medical Equipment

|

Medical Table Positioning Rack and Pinion System

Imaging Equipment Rack and Pinion Drive

Robotic Surgery Rack and Pinion Assembly

Prosthetic Limb Rack and Pinion Drive |

|

FAQ

1. What is the load capacity of the custom rack and pinion system?

The load capacity of the custom rack and pinion system is dependent on several factors, including the size and material of the rack and pinion components, the gear ratio, and the application requirements. We can work with you to determine the load capacity needed for your specific application and design a custom solution that meets those requirements.

2. What is the speed of the custom rack and pinion system?

The speed of the custom rack and pinion system is dependent on the gear ratio selected. We can work with you to determine the required speed for your application and select an appropriate gear ratio to achieve that speed.

3. What is the precision of the custom rack and pinion system?

The precision of the custom rack and pinion system is dependent on several factors, including the gear ratio, the size and material of the rack and pinion components, and the manufacturing process used. We can work with you to determine the precision requirements of your application and design a custom solution that meets those requirements.

4. What are the dimensions of the custom rack and pinion system?

The dimensions of the custom rack and pinion system will be determined by the application requirements. We can work with you to determine the necessary dimensions for your application and design a custom solution that meets those requirements.

What lubrication method and frequency should be used for the

5. Custom rack and pinion system?

The lubrication method and frequency for the custom rack and pinion system will depend on several factors, including the application requirements, the materials used for the rack and pinion components, and the operating environment. We can work with you to determine the most appropriate lubrication method and frequency for your application.

6. What materials and coatings should be used for the custom rack and pinion system to withstand the environmental factors of the application?

The materials and coatings used for the custom rack and pinion system will depend on the specific environmental factors of the application, such as temperature, humidity, and corrosive substances. We can work with you to determine the most appropriate materials and coatings to ensure the system can withstand the operating environment.

7. What are the mounting options for the custom rack and pinion system?

The mounting options for the custom rack and pinion system will depend on the application requirements. We can work with you to determine the necessary mounting options and design a custom solution that meets those requirements.

8. What is the lead time for the custom rack and pinion system to be manufactured and delivered?

The lead time for the custom rack and pinion system will depend on several factors, including the complexity of the design, the materials and coatings used, and the manufacturing process required. We can provide you with an estimated lead time once we have a better understanding of your specific requirements.

9. What is the warranty and support for the custom rack and pinion system?

We offer a warranty for our custom rack and pinion systems, which will vary depending on the specific system and application. We also offer technical support and maintenance services to ensure the system continues to operate effectively.

10. Can the custom rack and pinion system be modified or adjusted if necessary?

Yes, we can modify or adjust the custom rack and pinion system if necessary to ensure it meets the changing requirements of your application.

Application Field

Customer Photos

Customer Reviews

FAQ

1. Are you a manufacturer or a trading company?

We are a factory located in Shenzhen, China, with 20 years of rich experience,

covering 6000 square meters. Complete facilities, including 3D quality inspection equipment, ERP system and 40 machines. If necessary, we can provide you with material certificates, sample quality inspection and other reports.

covering 6000 square meters. Complete facilities, including 3D quality inspection equipment, ERP system and 40 machines. If necessary, we can provide you with material certificates, sample quality inspection and other reports.

2. How to get a quote?

Detailed drawings (PDF/STEP/IGS/DWG...), including quality, delivery date, materials, quality, quantity, surface treatment and other information.

Detailed drawings (PDF/STEP/IGS/DWG...), including quality, delivery date, materials, quality, quantity, surface treatment and other information.

3. Can I get a quotation without drawings?

Can your engineering team draw for my creativity? Of course, we are also glad to receive your samples, pictures or detailed size drafts for accurate quotation.

4. Can you provide samples before mass production?

Of course, the sample fee is necessary. If possible, it will be returned during mass production.

5. What is the delivery date?

Generally, the sample lasts for 1-2 weeks and the batch production lasts for 3-4 weeks.

6. How do you control quality?

(1) Material Inspection - Check material surfaces and approximate dimensions.

(2) First inspection of production - ensure

critical dimensions in mass production.

(3) Sampling inspection - check the quality before delivery to the warehouse.

(4) Preshipment inspection - 100% inspection by QC assistant before shipment.

7. After sales service team

Hot Searches