- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Trumony

-

product name:

-

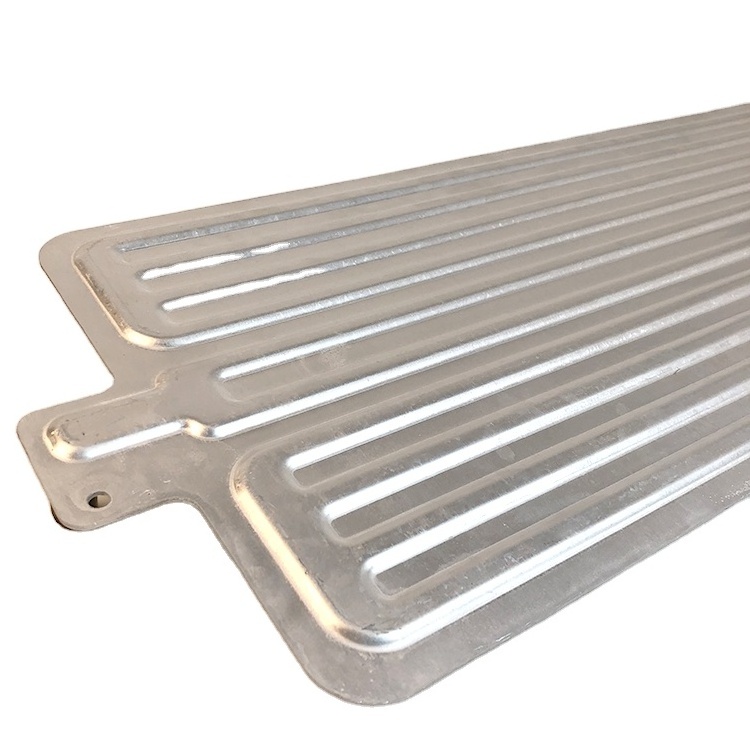

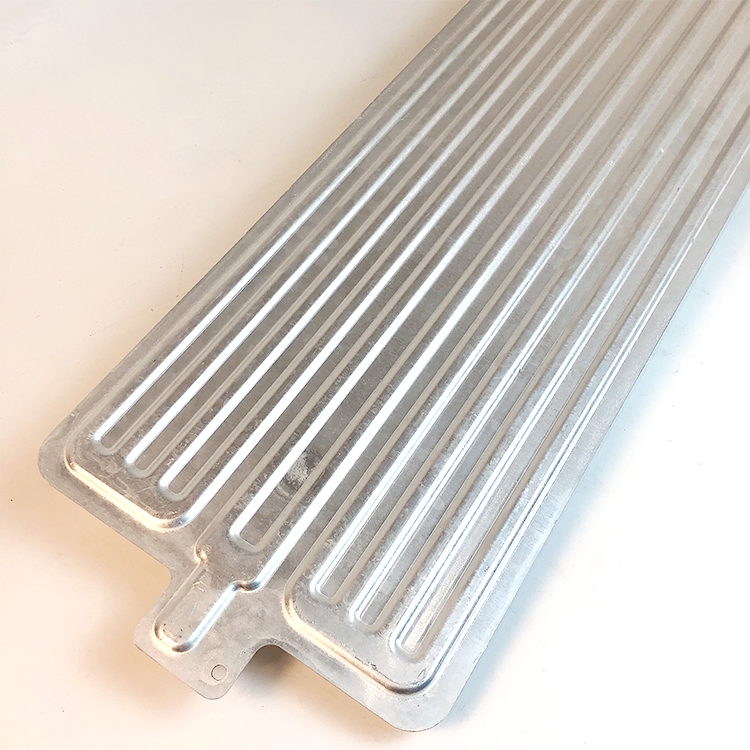

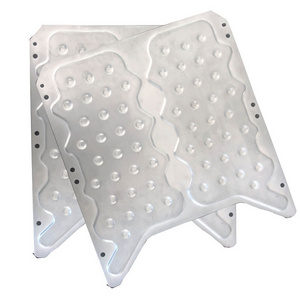

Stamping Process Aluminum Liquid Cold Plate For Cooling System

-

Keywords:

-

Liquid Cooling Plate

-

color:

-

sliver

-

Material:

-

Aluminum Alloy

-

Surface:

-

Mill Finish

-

Certification:

-

TS16949

-

Packing:

-

Standard Seaworthy Packing

-

Payment Term:

-

30% Deposit+70% Balance

-

After Warranty Service:

-

Video technical support

Quick Details

-

Type:

-

Heat Exchanger Plate

-

Application:

-

water cooling parts

-

Weight (KG):

-

3

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Trumony

-

product name:

-

Stamping Process Aluminum Liquid Cold Plate For Cooling System

-

Keywords:

-

Liquid Cooling Plate

-

color:

-

sliver

-

Material:

-

Aluminum Alloy

-

Surface:

-

Mill Finish

-

Certification:

-

TS16949

-

Packing:

-

Standard Seaworthy Packing

-

Payment Term:

-

30% Deposit+70% Balance

-

After Warranty Service:

-

Video technical support

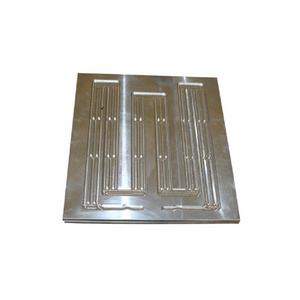

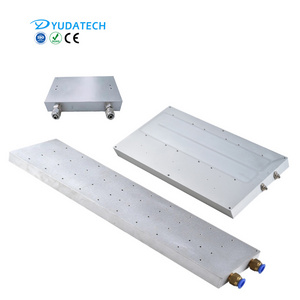

High Precision Stamping Process Aluminum Liquid Cold Plate For Cooling System

Features and Benefits

1. Tooling development — we do it in house, so we can make initial testing prompt and accurate.

2. Making all kinds of heat exchangers — we can do customized shape, to make the parts fit into different packs.

3. Assistance in parts design — we have experienced engineer team, they can provide professional suggestions regarding feasibility of carrying out new designs.

4. One station service — we can do heat exchangers, as well as its related insulation and silicon pad. So client can get

integrated solution.

Specifications

1. 3003 and other series aluminum alloy

2. anodizing, polishing, turning, power coating, mill finish etc

3. OEM, ODM, or design by ourselves

4. CNC ,extruding machine, cold drawn machine, heating oven, straightening machine, cutting machine

|

Item

|

High Precision Stamping Process Aluminum Liquid Cold Plate For Cooling System

|

|

|

|

|||

|

Alloy

|

3003,4343 or customized

|

|

|

|

|||

|

Temper

|

O,H14,H16 or customized

|

|

|

|

|||

|

Thickness

|

1-10 mm or Customized

|

|

|

|

|||

|

Application

|

Heat exchanger/ heat sink for battery cooling thermal management

|

|

|

|

|||

What can we do ?

Trumony Aluminium Limited,

We are a professional battery pack heat exchanger manufacturer.

Our company designs, makes and distributes heat exchangers for battery packs, which carrying cylindrical cells, prismatic cells or pouches.

I knew that you are looking for aluminum cooling channel for battery pack,We have full solutions about cooling the battery cells, for example snake tubes for cylindrical cells (18650,21700); water cooling plate for prismatic cells, and plate channel for pouches.We do hope to utilize our expertise to have chance to establish long-term cooperation with you , as battery thermal management is very critical in an operation of EV. Here are a few things we are good at:

1. Tooling development — we do it in house, so we can make initial testing prompt and accurate.

2. Making all kinds of heat exchangers — we can do customized shape, to make the parts fit into different packs.

3. Assistance in parts design — we have experienced engineer team, they can provide professional suggestions regarding feasibility of carrying out new designs.

4. One station service — we can do heat exchangers, as well as its related insulation and silicon pad. So client can get

integrated solution.

Q: Are you a trading company or manufacturer?

A: Yes,we are a factory with more than 10 years history in this industry.

Q: What is your terms of payment ?

A: Normally 30% TT in advance, balance paid before shipment.

Q: How long does it take for samples and mass production?

A: Usually it will take 15-20 days for new molds and free samples (within 5 kg),;after confirmation, 25-30 days for mass production.

Q: OEM/ODM available?

A: Yes,we can!

Q: Could you provide sample?

A: Yes, We are honored to offer you samples for quality check.

Q: Is sample order accepted?

A: Yes,we accept sample order and we can provide design service!