- Product Details

- {{item.text}}

Quick Details

-

Product Name:

-

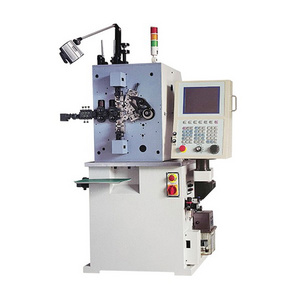

CNC Coiler Auto Conical Spring Coiling Machine for Sale

-

Color::

-

Optional

-

Size::

-

1900*2200*1400mm

-

Max wire feed speed::

-

0-70m/min

-

Cam instruction value ::

-

±0.1°-±359.9°

-

Cam rotation speed ::

-

1-60rpm

-

Wire feed servo power ::

-

7.0kw

-

Cam servo motor::

-

7.0kw

-

Power supply::

-

380V±10%V50HZ

-

Weight::

-

1950kg

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

HITECH

-

Weight (KG):

-

1950

-

Product Name:

-

CNC Coiler Auto Conical Spring Coiling Machine for Sale

-

Color::

-

Optional

-

Size::

-

1900*2200*1400mm

-

Max wire feed speed::

-

0-70m/min

-

Cam instruction value ::

-

±0.1°-±359.9°

-

Cam rotation speed ::

-

1-60rpm

-

Wire feed servo power ::

-

7.0kw

-

Cam servo motor::

-

7.0kw

-

Power supply::

-

380V±10%V50HZ

-

Weight::

-

1950kg

Product Introduction

The HT series CNC spring machine computer has an English interface, which is easy to operate and accurate in positioning. Thecomputer can control three to eight servo motors. All motors can operate synchronously or independently. It is equipped with precision detection and tracking equipment. If there are unqualified products, it can automatically stop. According to the working conditions on the evaluation screen, the external diameter angle of the products can be maintained at any time. The automatic mechanical parts are designed with automatic lubrication and oil supply to ensure the long-term operation of the equipment. The automatic stop design and automatic acceleration function of the wire rack make the production easier and more effective when wireless, broken or entangled. It is applicable to the production of double torsion springs, straight springs, pagoda springs, tension springs, rectangular springs, wire forming, steel sheet vortex springs, spring springs and various fancy springs, as well as miscellaneous and difficult special-shaped springs.

.

|

Modle

|

HT-8208

|

HT-8212

|

HT-8320

|

HT-8322

|

HT-8335

|

HT-8345

|

HT-8350

|

|

Wire diameter of coiled material

|

ɸ0.15-ɸ0.8mm

|

ɸ0.2-ɸ1.2mm

|

ɸ0.4-ɸ2.0mm

|

ɸ0.2-ɸ2.5mm

|

ɸ0.5-ɸ3.5mm

|

ɸ1.0-ɸ4.5mm

|

ɸ1.0-ɸ5.0mm

|

|

Number of Axles

|

2 Axles

|

2 Axles

|

3 Axles

|

3 Axles

|

3 Axles

|

3 Axles

|

3 Axles

|

|

Wire feed instruction value

|

±0.01-±9999.99

|

±0.01-±9999.99

|

±0.01-±9999.99

|

±0.01-±9999.99

|

±0.01-±9999.99

|

±0.01-±9999.99

|

±0.01-±9999.99

|

|

Cam instruction value

|

±0.10°-±359.9°

|

±0.10°-±359.9°

|

±0.10°-±359.9°

|

±0.10°-±359.9°

|

±0.10°-±359.9°

|

±0.10°-±359.9°

|

±0.10°-±359.9°

|

|

Max outer diameter of coiled spring

|

Maxɸ20mm

|

Maxɸ20mm

|

Maxɸ60mm

|

Maxɸ60mm

|

Maxɸ80mm

|

Maxɸ80m

|

Maxɸ80m

|

|

Wire feed servo power

|

1.0KW

|

1.2KW

|

2.7KW

|

2.7KW

|

4.5KW

|

5.5KW

|

7.0KW

|

|

Cam servo motor

|

1.0KW

|

1.0KW

|

2.7KW

|

2.7KW

|

4.5KW

|

5.5KW

|

7.0KW

|

|

Power supply

|

380V±10%V50HZ

|

380V±10%V50HZ

|

380V±10%V50HZ

|

380V±10%V50HZ

|

380V±10%V50HZ

|

380V±10%V50HZ

|

380V±10%V50HZ

|

|

Size

|

1000*950*1600mm

|

1000*1000*1600mm

|

900*900*1300mm

|

1500*900*1900mm

|

1700*1300*2000mm

|

1700*1300*2000mm

|

1700*1300*2000mm

|

|

Weight

|

350kg

|

400kg

|

460kg

|

880kg

|

1500kg

|

1800kg

|

1950kg

|

Features and Functions

1. Adopt Taiwan imported computer control system and imported servo motor.

2. The computer has an English interface, which is easyto operate and accurate in positioning. The computer can control three to eight servo motors, and all motors can run synchronouslyor independently.

3. It is equipped with precision detection and tracking system. If there are unqualified products, it canautomatically stop. 4. According to the working conditions on the fluorescent screen, the outer diameter and angle of the product can be repaired at any time.

5. The automatic lubrication and oil supply design of mechanical automatic parts ensures the long-term operation of the equipment.

6. When there is no wire, broken wire, tangled wire, machine automatic shutdown design and wire rack automatic acceleration function, make the production easier and more effective.

7. It is suitable for the production of straight springs, pagoda springs, tension springs, rectangular springs, wire forming, steel scroll springs, springs and various fancy springs, complex and difficult special-shaped springs.

Hot Searches