- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

110V/120V/127V/208V/220V /240V/380V/415V/460V

-

Power:

-

16kw

-

Dimension(L*W*H):

-

4 m3

-

Weight (KG):

-

1500

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Power supply:

-

3*380V, 50/60HZ

-

Flame speed:

-

2100m/s

-

hardness:

-

1450

-

binding strength:

-

90MPa

-

Dual Compressors:

-

Water cooling

-

Coating porosity:

-

<1%

-

HVOF spray machine powder:

-

Tungsten Carbide WC-Co,TiC,Cr3C2-NiCr,NiCr18Al

-

equivalent to advanced foreign system:

-

easy to operate

-

eact with system breakdown:

-

monitor the system and control the spray gun real-time

Quick Details

-

Machine Type:

-

tungsten carbide alloy powder, Coating Equipment

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

HVOF Coating spraying repair gun

-

Voltage:

-

110V/120V/127V/208V/220V /240V/380V/415V/460V

-

Power:

-

16kw

-

Dimension(L*W*H):

-

4 m3

-

Weight (KG):

-

1500

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Power supply:

-

3*380V, 50/60HZ

-

Flame speed:

-

2100m/s

-

hardness:

-

1450

-

binding strength:

-

90MPa

-

Dual Compressors:

-

Water cooling

-

Coating porosity:

-

<1%

-

HVOF spray machine powder:

-

Tungsten Carbide WC-Co,TiC,Cr3C2-NiCr,NiCr18Al

-

equivalent to advanced foreign system:

-

easy to operate

-

eact with system breakdown:

-

monitor the system and control the spray gun real-time

Introduction: WC-Co-Cr Agglorated & Sintered Tungsten Carbide Based metal alloy Powders with cobalt and chromium painting aluminum

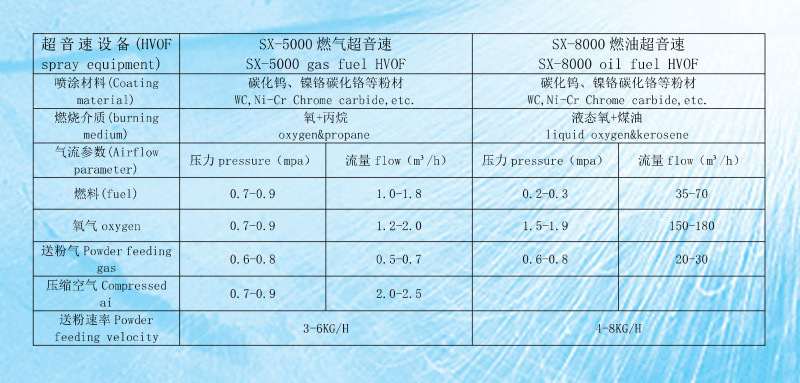

SANXIN provides SX-5000(gas fuel HVOF) & SX-8000(oil fuel HVOF) equipments.

SX-5000 a mixture of gaseous or liquid fuel and oxygen is fed into a combustion chamber, where they are ignited and combusted continuously. The resultant hot gas at a pressure close to 1 MPa emanates through a converging–diverging nozzle and travels through a straight section. The jet velocity at the exit of the barrel (>1000 m/s) exceeds the speed of sound. A powder feed stock is injected into the gas stream, which accelerates the powder up to 800 m/s. The stream of hot gas and powder is directed towards the surface to be coated. The powder partially melts in the stream, and deposits upon the substrate.

SX-8000 supersonic flame spraying is a new type of HVOF system, Its principle is that the combustion supporting agen oxygen atomizes the kerosene fully with atomizing nozzle, then they will enter into combustion chamber as flammable mixed gas.It will burn in high temperature and high pressure after the ignition system ignites it. high-temperature and high-pressure supersonic flame flow will be formed after it’s burning in the Laval nozzle. powder feeding system will send the powder material from the area of low pressure into the flame flow, heating accelerated then spray to the workpiece surface to form high quality coatings.

HVOF coating machine spray materials

HVOF coating machine can spray metarial of part of Alloy powder (

Tungsten carbide /WC-Co, Cr3C2-NiCr, MCrAlY, Cr C, Cr Co, Cr, etc

.)

HVOF equipment consists of HVOF spray gun , HVOF powder feeding machine , HVOF control system , heat-exchanger system for HVOF and pipeline system for HVOF.it's a compact equipment with the traits of easy-operating, stable working performance, low fuel consumption and high-quality coating.

Our company specializes in the production of arc spraying machines, HVOF supersonic flame spraying machines , plasma spraying machines, high-power flame spraying equipment , thermal spraying auxiliary equipment and automated coating line.

we has rich experience of manufacturing and construction applications more than 34 years in thermal spray field . We can provide a full set of technical support, including the best cost-effective equipments, onsite construction services , solution and process and any other support you need. hope to cooperate with agents and wholesalers from all over the world with high quality and the best price , we provide OEM production . Welcome to visit our factory in GUANGZHOU China .

We also provides diversified services

(1)Diversified thermal

(2)Spraying Equipment and coating

(3)Intelligent production line

(4)New coating service

(5)Soundproof room standard

(6)Power Boiler Global Construction

(7)Aerospace coating

(8)Medical coating TI HA

(9)Pulverizing system

(10)Auto parts anti-wear insulation

(11)Coated silicon aluminum target manufacturing

(12)Import and export equipment

(13)Raw material selection

This is our contact info

Skype: bermanhk

Whatapp / Mobile: +86 135 3322 3230

WeChat: 89995318

E-mail: thermalspray86#gmail.com (# repaired @)

Offical Web: http://www.sx-spray.com

Youtube: https://www.youtube.com/channel/UChtnCZL7KnF_p4Dxz8b9dgg

Wooden cases or iron box by sea

Parameters of HVOF coating machine

Parameters of hovf powder feeding machine

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Other Main Thermal Spraying Equipments and Service:

(1) Arc spray equipment

(2) Plasma spray equipment

(3) Vacuum Plasma Spray Machine

(4) Sputter Target Produce Equipment and technology

(5) Precious metal vacuum coating equipment

(6) Cooker magnetism and thermal conduction coating spraying production line Thermal

(7) Industrial water chillers

(8) Spray Coating Services

(9) Electro Brush Plating Equipment

(10) High power flame spray plastic equipment

Spray Coating Application Cases