- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-1mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

KEFA

-

Voltage:

-

380V 50Hz 3phases

-

Dimension(L*W*H):

-

5000mm*1000mm*1300mm

-

Weight:

-

5 kg

-

Certification:

-

CE/ISO9001

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Colored Glaze Steel

-

Production Capacity:

-

Other

-

Rolling thinckness:

-

0.3-1mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

KEFA

-

Voltage:

-

380V 50Hz 3phases

-

Dimension(L*W*H):

-

5000mm*1000mm*1300mm

-

Weight:

-

5 kg

-

Certification:

-

CE/ISO9001

Advantages of shelf layer panel cold roll forming machine

1.The width be automatic adjusted by PLC.

2.shelf layer panel cold roll forming machine adopts memorial arch frame type,independent roller station make the machine more beautiful and stability.

3.All the rollers are through quench treatment ,CNC machine treatment twice and polished on the surface to guarantee the accuracy and long life.

4.we also have other type of shelf layer panel cold roll forming machine.It is with the whole adjusting system to change the sizes of the shelf panel. it no need to change the spacer one by one, just change the screw whole on the machine so that can adjust different sizes. this design is much convenient and quick than the changing spacer machine line.

5.The cutting is hydraulic cutting, you can change different blades for different sizes of the shelf.

|

Decoiler :

|

Manual decoiler

|

* Hydraulic decoiler (Optional)

|

|

Forming station :

|

According to your profile drawings

|

* With straighten revise rollers

|

|

Main machine motor brand :

|

Shanghai Lichao (Famouse Brand)

|

* Siemens (Optional)

|

|

Driving system :

|

Chain drive or Gear drive

|

* Gearbox drive (Optional)

|

|

Machine structure:

|

Cantilever type

|

* Forged Iron station (Optional)

|

|

Forming speed :

|

10-20 (M/MIN)

|

* Or according to your profile drawings

|

|

Rolling Shaft:

|

40Cr Steel Material

|

* (Modulation, fine turning, fine grinding)

|

|

Rollers’ material :

|

CR12 Steel (Quenching, fine turning and grinding of inner holes and surfaces, Hard chrome)

|

* SKD-11 (Optional)

|

|

Cutting system :

|

Post-cutting

|

* Pre-cutting (Optional)

|

|

Frequency changer brand :

|

Yaskawa

|

* Siemens (Optional)

|

|

PLC brand :

|

Delta,Touch Screen

|

* Siemens (Optional)

|

|

Power supply :

|

380V 50Hz 3ph

|

* Or according to your requirment

|

|

Machine color :

|

Industrial blue

|

* Or according to your requirment

|

|

Runout Table:

|

Roller type,non-power

|

* Motorized,Drop off,auto stack(Optional)

|

De-Coiler is provided to load Raw material coil on its bridge& Hold the coil and also in loop area store the row material before in process. It will hold tighten sheet coil & decoiling for roofing line smoothly.

7 rolls leveling, 3 rolls up and 4 rolls down

Diameter is Ø 80mm, chrome and HRC60 heat treatment to secure the smooth surface

Leveling Raw Material thickness:1.6mm

Max Leveling Raw Material width: 500mm

Servo Feeder

Usage: Applied to control the width and position of the steel sheet,which is guided into the correct position of machine to make sure the panel is neat and parallel.

1. Nc-500 CNC feeder + GO500

2. Power: 2.3KW

3. Working width: 500 mm

4. Working thickness range: 1.6mm

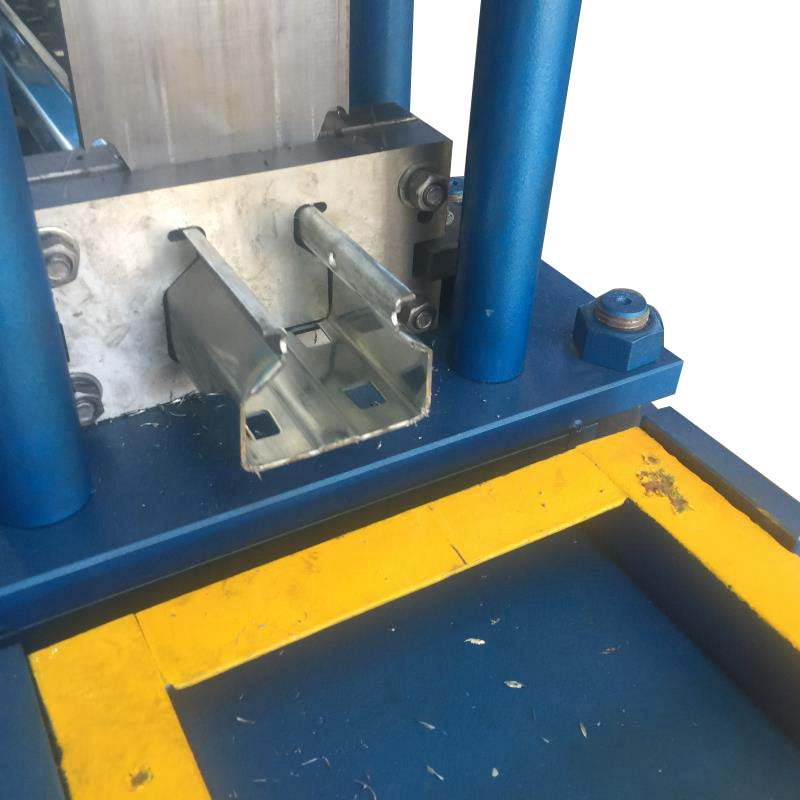

Hydraulic Press

Hydraulic Punch: Hydraulic Punch,high precision and automatic

Punching Mold Material:SKD11, heat treatment,quenched to 58 - 62 °

Holes distance can be set on PLC ,and automatically punch.

Punching holes after roll forming,Includes side and end holes, which can achieve the Angle corner and holes connection requirements of the cabinet.

Entry Guides

1. With several support rollers, to feed the material more smoothly

2. Equipped with 2 groups nylon wheels in the middle of the platform, prevent the material surface from being damaged, and feed the material more easily and quickly

3. Can be With hand wheels to adjust the feeding size, more conveniently.

4. Optional With manual cutters to cut feed material more easily.

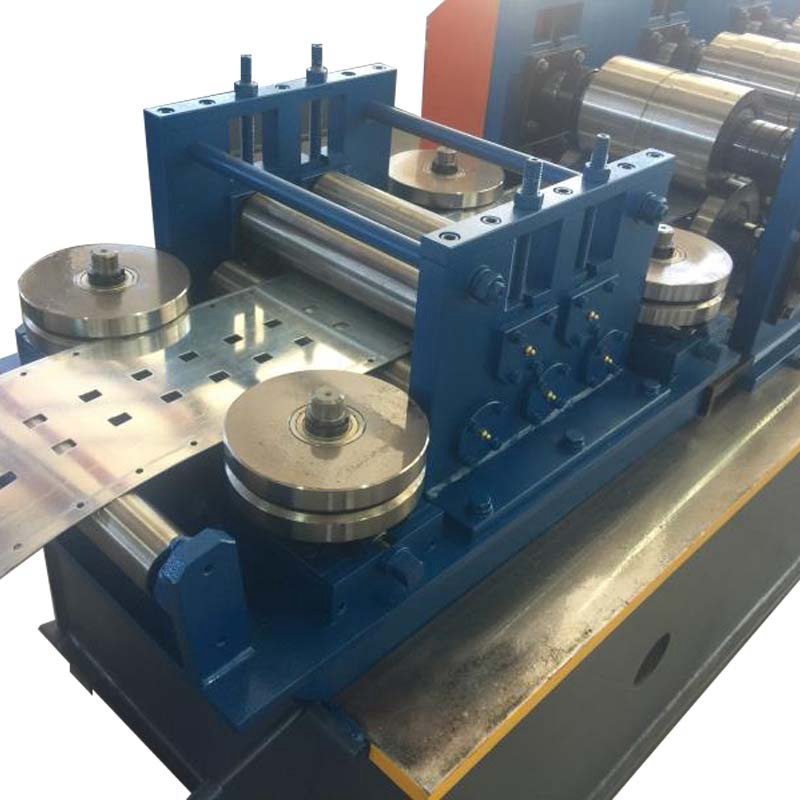

Roll Forming

Consist pairs of contoured roll tools. While the coil stock is passing through succession contoured rolls the material bends to

its desired shape. 1.Rolling shaft :40Cr STEEL,Tempering treatment to prevent deformed and improve hardness,Shaft diameter: 75mm

2.Roller:Cr12 steel,Chromed treatment, improve the hardness and prevent abrasion, anti corrosion increase service life.

its desired shape. 1.Rolling shaft :40Cr STEEL,Tempering treatment to prevent deformed and improve hardness,Shaft diameter: 75mm

2.Roller:Cr12 steel,Chromed treatment, improve the hardness and prevent abrasion, anti corrosion increase service life.

Flying Cutting

Work type:Hydraulic Non Stop cutting

Driving :By pillar type cylinder Cutting device structure:Guide pillar type Cutter material:

GB-Cr12 with heat treatment Cutting length tolerance:±1mm/3m Cutting feature: Steady and safe working condition Oil tube and wires

connection All the tubes and wires will be marked by the numbers or letters,So it will be very easy to connect for the

unprofessional client.

GB-Cr12 with heat treatment Cutting length tolerance:±1mm/3m Cutting feature: Steady and safe working condition Oil tube and wires

connection All the tubes and wires will be marked by the numbers or letters,So it will be very easy to connect for the

unprofessional client.

PLC & CONTROL PANELS

Frequency brand:Delta,PLC brand:Delta Screen type:Touch screen, also have buttons on the panel Screen language:English /Chinese /Spanish Low pressure electric part:Schneider brand Encode:Omron brand Remark:Support multi orders input,ensure the machine can work continuously according to different request without stop. All the electrical parts are branded with high quality, it can be fixed easily if damaged.

Box Beam

Square Post

Heavy Rack

P Beam

1.How to maintain the machine?

Answer: add mechanical lubrication equipment to chain, bearing and cutting slide every month. Add mechanical lubrication to the case every half a year.

2. Do you sell only standard machines?

A: No, most of our machines are built according to customers specifications, using top brand name components.

3.How many workers to operate the machine?

A:Only 1-2 workers.

4. How to visit your company?

a.Fly to Beijing airport: By high speed train From Beijing Nan Station to Cangzhou West Station(1 hour), then we can pick you up .

b.Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou West station(4.5 hours), then we can pick you up.

5. What can you do if the machine broken?

Our machine's warranty period is 12months,if the broken parts can't be repaired,we can send the new parts to replace the broken parts for free,but you need pay the express cost yourself.if over warranty period,we can for to solve the problems via negotiation,and we supply the technical support for the whole life of the equipment.

6.How can I trust you that machines pasted testing running before shipping?

A: 1) We record the testing video for your reference. Or,

2) Please visit company and test machine if convenient.

Hot Searches