- Product Details

- {{item.text}}

Quick Details

-

Material:

-

Mild steel, SUS304/316, FRP stainless steel

-

Weight:

-

1500 kg- 10000 kg

-

Size:

-

12.5*4.8*3.0

-

Power:

-

20.9kw/h

-

Weight (KG):

-

1500 kg

-

Brand:

-

JORSUN

-

Type:

-

DAF2-150

-

Capacity:

-

150000L/H

-

Usage:

-

Water Treament

-

Hydraulic loading:

-

5-8 m/h

-

Feature:

-

Packaged design

-

Meterial:

-

Carbon steel and stainless steel SUS304/316 PVC

-

Key words:

-

sludge hopper

-

Function:

-

sedimentation tank

-

Keywords:

-

automation

Quick Details

-

Warranty of core components:

-

18 months

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

JORSUN

-

Material:

-

Mild steel, SUS304/316, FRP stainless steel

-

Weight:

-

1500 kg- 10000 kg

-

Size:

-

12.5*4.8*3.0

-

Power:

-

20.9kw/h

-

Weight (KG):

-

1500 kg

-

Brand:

-

JORSUN

-

Type:

-

DAF2-150

-

Capacity:

-

150000L/H

-

Usage:

-

Water Treament

-

Hydraulic loading:

-

5-8 m/h

-

Feature:

-

Packaged design

-

Meterial:

-

Carbon steel and stainless steel SUS304/316 PVC

-

Key words:

-

sludge hopper

-

Function:

-

sedimentation tank

-

Keywords:

-

automation

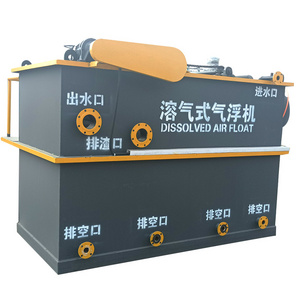

DAF Working Process

Dissolved Air Flotation is a solid/liquid or liquid/liquid separation process to remove tiny suspended

solids that density close to water, colloid ,oil and grease etc.

DAF will generate a large numbers of micronano bubbles (3 ~ 20μm) ,which will be as carrier to mix,

contact and adhere to the suspended solids, and bring the SS to float to the liquid surface. Then the

floating scums will be removed by top skimmer to achieve the purpose of separation of impurities,

and water purification.

Features

1. Customized design, meet variable requirements.

2. Fairly adapt to the sewage with large amount of sedimentation ( rich particles, greese and colliod ).

3. Fully (100%) manufactured in the factory, and no need secondary welding, also it takes 2 workers 3h to assemble.

4. Indoor or outdoor layout (environment temperature/Fahrenheit should be over 0 ° C /32 ° F,

water temperature/Fahrenheit should be no less than 42 ° C/107.6 ° F).

5. Apply to automatic & continuous operation.

DAF Application Field

1. Industrial wastewater treatment: food, pharmacy, textile&dyeing, semiconductor, machining

process, steel, chemical,animal breeding & slaughter etc .

2. Wastewater Treatment Plant (WWTP): upgrade , phosphorous removal.

3. Water Treatment Plant (WTP): algae removal.

4. Ecological environment: water purification of river, lake and landscape.

5. Sea water desalination.

Superiority

1. Stable performance ,reliable operation .

2. Huge markets,high cost-effective solution.

3. Automatic scum removal, adjustable solid content according to actual demand.

4. Hydraulic load 5-8 m/h.

5. Packaged design, nice bending reinforcement appearance.

6. A nti-corrosion treatment and no blind angle.

7. DAF2 model with “V” or “W” type sludge hopper is especially

8. designed for wastewater with precipitation phenomenon.

Our Services

1. Detailed installation manual and maintenance guideline are provided with the equipment.

2. Technical training and site-commissioning are available for you.

3. Any question in regard to the equipment could be solved at any time.

|

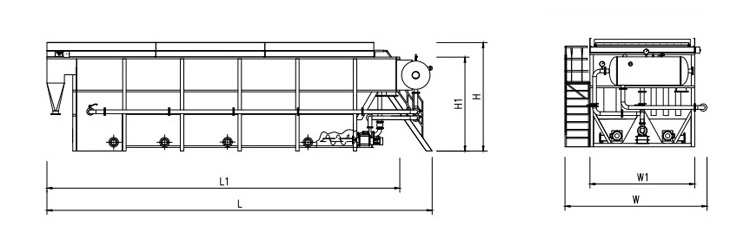

Model |

Capacity |

Power(kw) |

Dimension(m) |

Nozzle list(DN) |

|||||||

|

(m^3/h) |

Recirlation pump |

Air compressor |

Skimmer |

L/L1 |

W/W1 |

DAF H/H1 |

DAF2 H/H1 |

Inlet |

Outlet |

Sludge scraper |

|

|

DAF-003 |

~3 |

0.75 |

0.55 |

0.2 |

3.6/2.8 |

2.4/1.16 |

2.2/1.7 |

/ |

50 |

50 |

100 |

|

DAF-005 |

~5 |

1.1 |

0.55 |

0.2 |

3.9/3.1 |

2.4/1.16 |

2.2/1.7 |

/ |

80 |

50 |

100 |

|

DAF/DAF2-010 |

~10 |

1.1 |

0.55 |

0.2 |

4.3/3.3 |

2.9/1.66 |

2.3/1.9 |

2.7/2.2 |

100 |

100 |

100 |

|

DAF/DAF2-020 |

~20 |

3.0/5.5 |

0.75 |

0.2 |

5.4/4.4 |

3.2/2.16 |

2.3/1.9 |

2.7/2.2 |

150 |

100 |

100 |

|

DAF/DAF2-030 |

~30 |

3.0/5.5 |

0.75 |

0.2 |

6.5/5.5 |

3.2/2.16 |

2.3/1.9 |

2.7/2.2 |

150 |

150 |

150 |

|

DAF/DAF2-040 |

~40 |

3.0/5.5 |

0.75 |

0.2 |

6.5/5.5 |

3.7/2.7 |

2.3/1.9 |

2.7/2.2 |

150 |

150 |

150 |

|

DAF/DAF2-050 |

~50 |

7.5 |

1.5 |

0.2 |

7.3/6.2 |

3.7/2.7 |

2.3/1.9 |

2.7/2.2 |

200 |

150 |

150 |

|

DAF/DAF2-060 |

~60 |

7.5 |

1.5 |

0.2 |

7.9/6.5 |

4.0/3.0 |

2.7/2.3 |

3.0/2.6 |

250 |

200 |

150 |

|

DAF/DAF2-080 |

~80 |

11 |

1.5 |

0.2 |

9.7/8.3 |

4.0/3.0 |

2.7/2.3 |

3.0/2.6 |

250 |

200 |

150 |

|

DAF/DAF2-100 |

~100 |

15 |

2.2 |

0.2 |

10.7/9.3 |

4.4/3.0 |

2.7/2.3 |

3.0/2.6 |

300 |

250 |

150 |

|

DAF/DAF2-120 |

~120 |

15 |

2.2 |

0.2 |

11.7/10.3 |

4.4/3.4 |

2.7/2.3 |

3.0/2.6 |

300 |

250 |

150 |

|

DAF/DAF2-150 |

~150 |

18.5 |

2.2 |

0.2 |

12.5/11.4 |

4.8/3.8 |

2.7/2.3 |

3.0/2.6 |

300 |

300 |

150 |

FAQ

Q: How to buy your idea products?

A:You can provide us your water sources, water quality, flow rate and ground area (connect us for more details).

Q:How to pay?

A:TT and L/C are acceptable and TT will be more appreciated. 30% deposit before producing, 70% balance before loading by TT.

Q:What is the delivery time?

A:It depends on order quantities. Generally speaking, the delivery time will be within 4 to 6 weeks.

Q:How to pack the products?

A:We use standard package. If you have special package requirements, we will pack as required, but the fees will be paid by customers.

Q:How to keep your equipments from corrosion?

A:We use the world-famous paint, like SigmaCoatings,PainBow,etc. What's more, we paint strictly according to the standard process.

Q:How do you manufacture your equipment?

A:Our machining technology includes laser/plasma cutting, automatic welding,CNC cutting and bending.

Q:How to install after the equipments arriving destination?

A:We will provide detailed illustrations to you. If it is necessary, we will send technicians to help you. However, the visa fee, air tickets, accommodation, wages will be paid by buyers.