- Product Details

- {{item.text}}

Quick Details

-

Max. Welding:

-

3000 mm x1800 mm

-

Min. Welding:

-

620 mmx 620 mm

-

Profile Height:

-

20 mm to 120 mm

-

Max. Profile Width:

-

120 mm

Quick Details

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Air Pressure:

-

0.5 to 0.8 MPa

-

Air Consumption:

-

200 L/min

-

Max. Welding:

-

3000 mm x1800 mm

-

Min. Welding:

-

620 mmx 620 mm

-

Profile Height:

-

20 mm to 120 mm

-

Max. Profile Width:

-

120 mm

pvc window door profiles CNC 4 heads welding machine/pvc window door corner cleaning machine

If the above product is not your cup of tea?

Never mind,

please click here

,leave product name you need

,leave product name you need

You will find more solutions.

PVC/UPVC window making machine

Description

WPL130 welding and cleaning line for door and window is typically used for welding and cleaning PVC door and window frame. It welds four corners of PVC profiles and cleans the welded corners. This welding-cleaning production line is mainly composed of welding unit, transfer unit, manipulator and corner cleaning unit. Thanks to Parker's unique, rigid and aesthetic design, this welding and cleaning line has high working speed. The original robot system can convey the corners to the cleaning unit without time loss. Besides, our welding-cleaning production lines have passed CE and UL certifications.

Features

1. Whole Machine

WPL130 welding and cleaning line adopts imported computer control system with high reliability and production ability. It can automatically program and select processing programs.

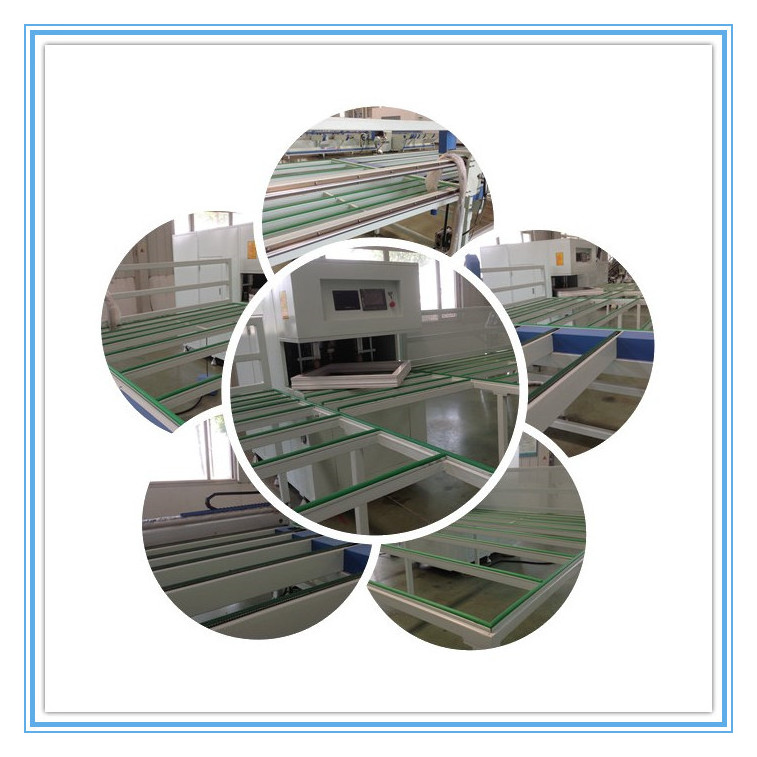

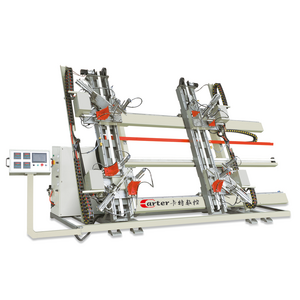

2. Welding Unit

This welding-cleaning production line uses horizontal structure for stable running. It realizes automatic size error compensation, high processing precision and high stability. Special locating system and impaction device ensure its size precision. Steel stand and low center of gravity ensure stable welding of this welding and cleaning line.

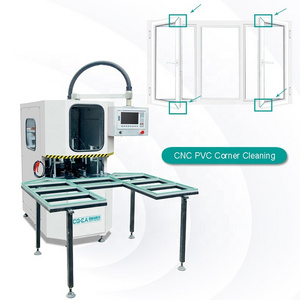

3. Cleaning Unit

This welding-cleaning production line owns eight groups of different cutters to achieve the cleaning of welded corners. Adopting four-axis servo-drive system contributes to high processing efficiency. Imported computer system and drive system also ensure high reliability of this welding and cleaning line. It is not necessary to change cutters to process more than one hundred profiles. Error compensation between arc and straight line is possible and gives good cleaning appearance.

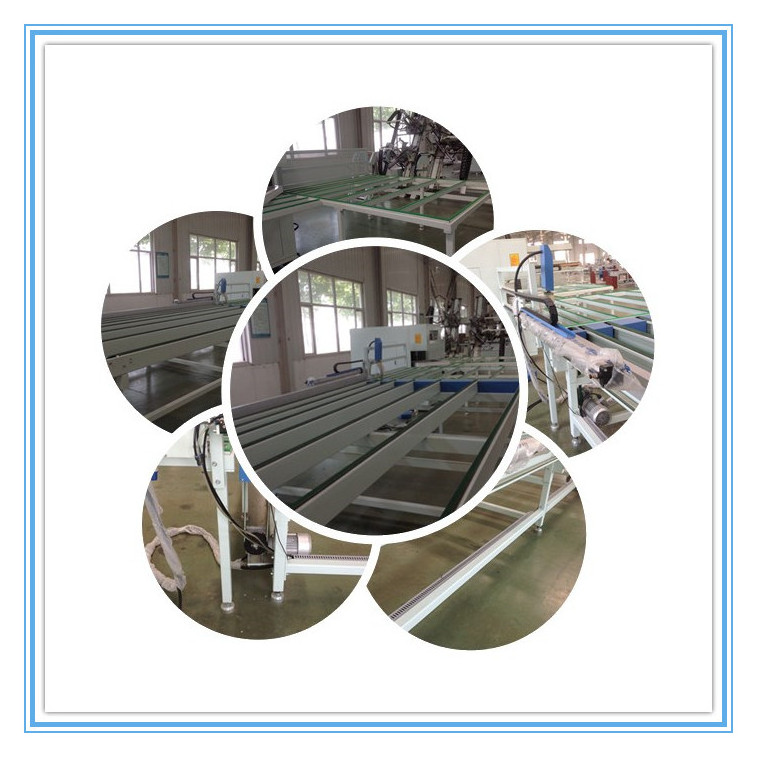

4. Transfer Unit and Manipulator

Transfer unit of this welding-cleaning production line is used for automatically conveying the finished frame or sash after welding. Manipulator is applied for transferring the frame or sash to the precise position.

Parameters of WPL130 Welding and Cleaning Line

| Voltage | 380V 50 Hz |

| Total Power | 14 kW |

| Air Pressure | 0.5 to 0.8 MPa |

| Air Consumption | 200 L/min |

| Max. Welding | 3000 mm × 1800 mm |

| Min. Welding | 620 mm × 620 mm |

| Profile Height | 20 mm to 120 mm |

| Max. Profile Width | 120 mm |

| Conveying Speed in the Middle Part | 30 m/min |

| Overall Dimension | 12600 mm × 6000 mm × 1700 mm |

| Weight of Welding-Cleaning Production Line | 5500 kg |