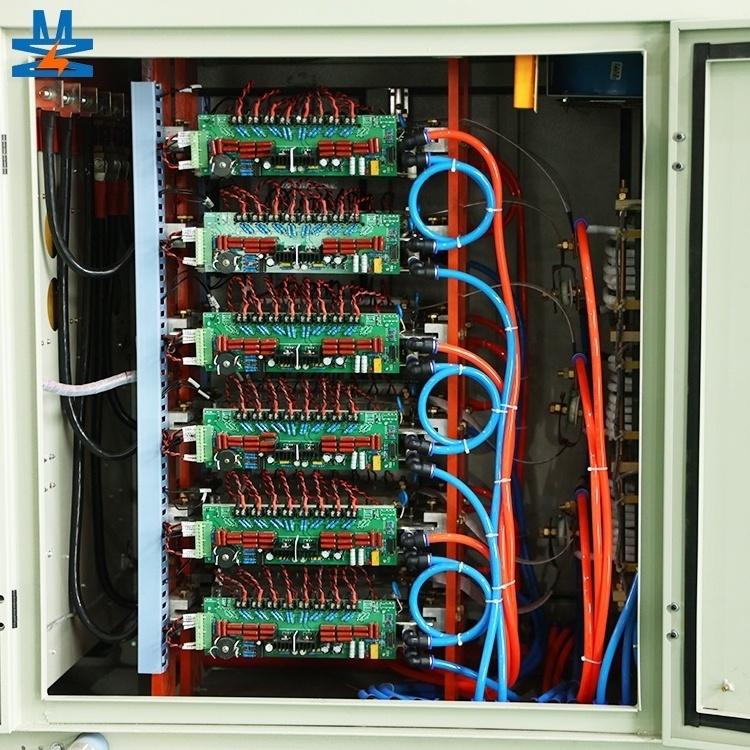

Diode all wave rectifying add IGBT chopping to replace SCR rectifying,it’s improving the power factor;The DC part and inverter part into one cabinet,which reduce the waterway and circuit between the cabinets,which is effectively avoiding the electrical interference and reducing the installation time.

The inverter part is consisted of MOSFET single phase invert bridge in parallel style.Each bridge’s design power is 120kW/60kW.We adopt building block mode to pile up power,it’s very convenient to install and maintain because every single bridge board is designed as drawer structure consisted of slideway.

We adopt matching transformer to realize power combination,also we adopt sub-resonance,no-welding transformer output mode and make resonance directly by tank resonance capacitor (low voltage) and inductor to achieve steel pipe welding power transmission bu output lead.

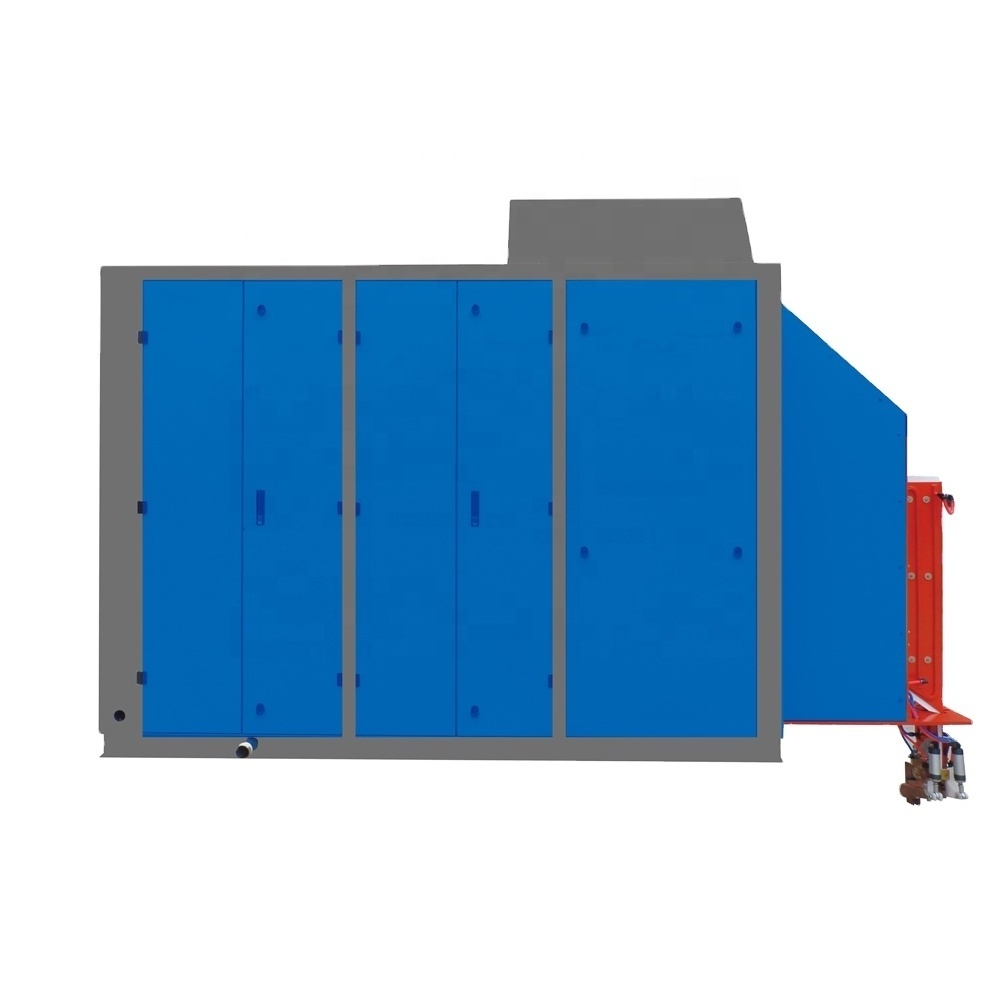

Use sealed box and install overhead air conditioning.