- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V 380V 440V or Customized

-

Dimension(L*W*H):

-

according to model

-

Power (kW):

-

75

-

Weight:

-

according to model

-

Screw Speed (rpm):

-

1 - 90 rpm

-

Raw material:

-

plastic flakes

-

Motor brand:

-

SIEMENS or customized

-

Inverter:

-

ABB

-

Contactor:

-

Schneider Brand

-

Temperature:

-

Omron/RKC

-

Cutting type:

-

water-ring cutting or cold strand cutting

-

Bearing brand:

-

HRB or customized

-

Air vent design:

-

natural air venting/vacuum force air vent

-

Stage:

-

mother and baby extruder

-

Marketing Type:

-

Ordinary Product

-

Screw L/D Ratio:

-

33:1

-

After-sales Service Provided:

-

Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Online support, Video technical support

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Egypt, Canada, Turkey, United Kingdom, United States, Italy, France, Germany, Viet Nam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Spain, Thailand, Japan, Malaysia, Australia, Morocco, Kenya, Argentina, South Korea, Chile, UAE, Colombia, Algeria, Sri Lanka, Romania, Bangladesh, South Africa, Kazakhstan, Ukraine, Kyrgyzstan, Uzbekistan, Tajikistan

-

Certification:

-

CE/ ISO9001

Quick Details

-

Output (kg/h):

-

50 - 1000 kg/h

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Polestar

-

Voltage:

-

220V 380V 440V or Customized

-

Dimension(L*W*H):

-

according to model

-

Power (kW):

-

75

-

Weight:

-

according to model

-

Screw Speed (rpm):

-

1 - 90 rpm

-

Raw material:

-

plastic flakes

-

Motor brand:

-

SIEMENS or customized

-

Inverter:

-

ABB

-

Contactor:

-

Schneider Brand

-

Temperature:

-

Omron/RKC

-

Cutting type:

-

water-ring cutting or cold strand cutting

-

Bearing brand:

-

HRB or customized

-

Air vent design:

-

natural air venting/vacuum force air vent

-

Stage:

-

mother and baby extruder

-

Marketing Type:

-

Ordinary Product

-

Screw L/D Ratio:

-

33:1

-

After-sales Service Provided:

-

Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Online support, Video technical support

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Egypt, Canada, Turkey, United Kingdom, United States, Italy, France, Germany, Viet Nam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Spain, Thailand, Japan, Malaysia, Australia, Morocco, Kenya, Argentina, South Korea, Chile, UAE, Colombia, Algeria, Sri Lanka, Romania, Bangladesh, South Africa, Kazakhstan, Ukraine, Kyrgyzstan, Uzbekistan, Tajikistan

-

Certification:

-

CE/ ISO9001

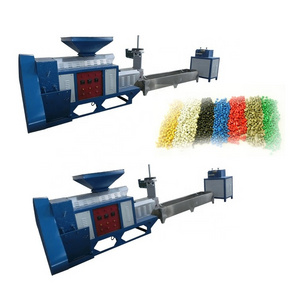

Product details:

As plastic is applied in more and more areas, waste plastic recycling emerges due to diverse area difference of cost and performance requirement. Through the firm’s own R&D efforts, PoleStar Machinery developed plastic recycling and granulation machines aiming at processing various rigid plastic products from injection moulding, blow moulding, rotational moulding, etc. PoleStar Machinery provides customers with various options, such as different L/D ratios, multiple exhaust screw structures, single and double stage design, different kinds of pelletizing die, capacity 100-1000kg/h line depending on your choice.

Competitive Advantages:

1.This line introduces Japanese technique, it can directly put PE/PP material into single-screw extrusion line for granulation after crushed and washing.

2.The extruder use large L/D screw, it bears special exhaust equipment and it can wipe off the liquid water content effectively and get high output.

3. All parts contacting with plastic material and water are made of high-quality 304 stainless steel; Ensure no second pollution to flakes.

4.Siemens contactor, RKC temperature controller

5.This line use water-ring pelletizer, granules are uniform and beautiful.

Main feature:

1. Highly automatic, user-friendly control, highly efficient, environmental protection and energy saving;

2. Different pelletizing ways, such as cold strand, water-ring, and underwater for various raw materials and production

requirements;

3. Multi-stations screen changer and automatic screen changing design can reduce manual labor and improve operation convenience;

4. Single and double stage, multi-exhaust and filtering system ensure high quality and products;

5. Suitable for diverse materials processing, also can specially design the machine for one material or different materials, which

can reduce customer's investment cost.

Technical parameter:

Single stage agglomeration granulation line

|

Model

|

70

|

90

|

100

|

120

|

150

|

180

|

|||||

|

Output (kg/h)

|

90-150

|

150-250

|

200-300

|

300-450

|

500-600

|

700-850

|

|||||

|

Power consumption (kWh/kg)

|

0.2-0.35

|

|

|

|

|

|

|||||

|

Main power (kW)

|

45

|

75

|

90

|

132

|

160

|

185

|

|||||

|

Screw outer diameter (L/D)

|

70(33:1)

|

90(30-35:1)

|

100(3035:1)

|

120

(30-33:1) |

150

(30-32:1) |

180

(30-32:1) |

|||||

|

Vacuum exhaust

|

Option

|

|

|

|

|

|

|||||

|

Screen changer

|

Standard configuration

|

|

|

|

|

|

|||||

|

Water-ring granulation

|

Option

|

|

|

|

|

|

|||||

|

Cold strand granulation

|

Option

|

|

|

|

|

|

|||||

|

Underwater granulation

|

Option

|

|

|

|

|

|

|||||

Double stage granulation line

|

Model

|

70+90

|

90+100

|

100+120

|

120+150

|

150+180

|

180+200

|

|||||

|

Output (kg/h)

|

110-180

|

150-250

|

200-300

|

300-450

|

500-650

|

700-850

|

|||||

|

Power consumption (kWh/kg)

|

0.2-0.35

|

|

|

|

|

|

|||||

|

Main power (kW)

|

30+22

|

55+30

|

75+37

|

90+45

|

110+55

|

160+75

|

|||||

|

Screw outer diameter(L/D)

|

70(25+12:1)

|

90

(25+12:1) |

100(25+12:1)

|

120(25+12:1)

|

150(25+12:1)

|

180(25+12:1)

|

|||||

|

Vacuum exhaust

|

Option

|

|

|

|

|

|

|||||

|

Screen changer

|

2 sets of standard configuration

|

|

|

|

|

|

|||||

|

Water-ring granulation

|

Option

|

|

|

|

|

|

|||||

|

Cold strand granulation

|

Option

|

|

|

|

|

|

|||||

|

Underwater granulation

|

Option

|

|

|

|

|

|

|||||

Zhangjiagang Polestar Machinery Co., Ltd. is a hi-tech company, professional in research, developement, production and sales of plastic machines. Polestar is located in Economy Development Zone, Zhangjiagang city, Jiangsu Province(only 120km from Shanghai,60km from Suzhou, and 50km from Wuxi).

For 15 years, Polestar devoted its mind to manufacturing plastic pipe extrusion lines, profile extrusion lines, washing recycling lines, pelletizing production lines, shredders, crushers, mixing units and some other auxiliary equipment. Until now more than 1000 lines are sold to domestic and many customers in the world.

With business principle of 'Quality is foundation and honesty is our first priority', we not only produce high quality machines, but also provide all-round technical support and service.

Polestar looks foward to cooperationg with you and will create a better furture for you!

Packing

:

Wood pallet and cover by plastic film

Service

:

Our Warranty is 1 year for whole machinery.

We will provide the technical advice and find the solution immediately for you when the machine is in trouble.For those wear parts, we guarantee the high quality parts for long-term supply.

Q: Where is your factory located? How can I visit there?

A: Our factory is located in Zhangjiagang city, Jiangsu province, When you confirm flight No. and time, please feel free to contact us, then we will pick up you on time.

Q: Why you choose our company?

A:1,Our company have mademachine forabout 20 years with strong experience and advanced technology.

2,we are factory direct sale ,provide you Best Quality and Service with Reasonable price.

Q: What's the trade term and payement term?

A: 30% or 50% T/T before production; Paid in full before shipment.

Q: Will you send the equipment to us directly after completion?

A: After the completion of the equipment,you must first come to the acceptance,confirm that there is no problem before delivery

Q: What price terms you offer?

A: FOB, CIF, EXW and other price terms based on your kind request.

Q: Installation and stuff training available from you?

A: Yes, our engineers will guide machine installation and train your workers.