- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

160 KG

-

Material:

-

Carbon Steel/ Stainless Steel 304

-

Layer:

-

1~3 Layers

-

Driving force:

-

Electricity

-

Capacity:

-

50-800 kg/h

-

Cleaning system:

-

Ultrasonic Cleaning device

-

Function:

-

Screening\separation\sorting\sieving

-

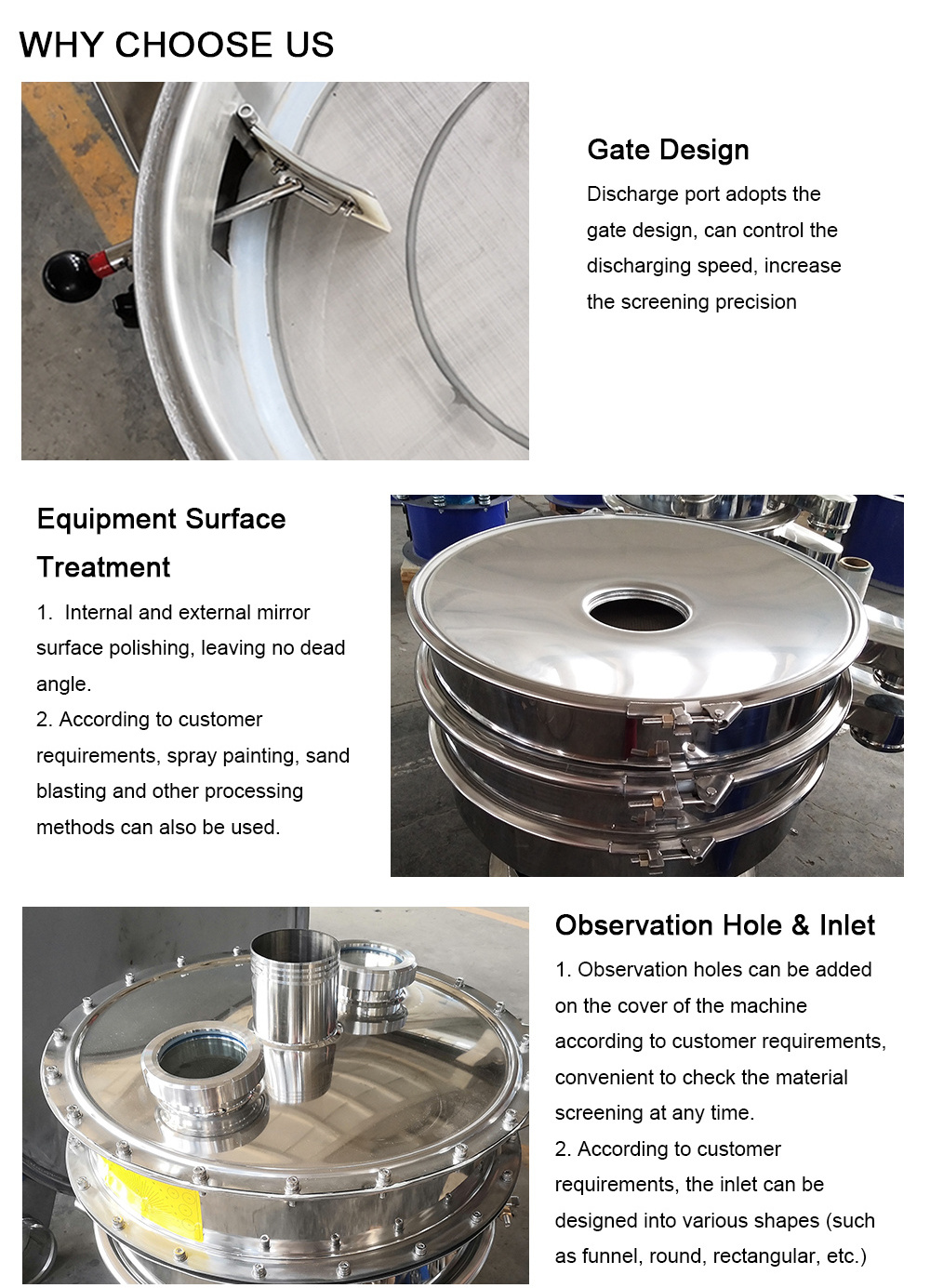

Surface treatment:

-

Surface treatment

-

Advantage:

-

High Sieving Precision

Quick Details

-

Type:

-

Circular

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Sanyuantang

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

160 KG

-

Material:

-

Carbon Steel/ Stainless Steel 304

-

Layer:

-

1~3 Layers

-

Driving force:

-

Electricity

-

Capacity:

-

50-800 kg/h

-

Cleaning system:

-

Ultrasonic Cleaning device

-

Function:

-

Screening\separation\sorting\sieving

-

Surface treatment:

-

Surface treatment

-

Advantage:

-

High Sieving Precision

Product Overview

High Frequency Ultrasonic Vibrating Screen

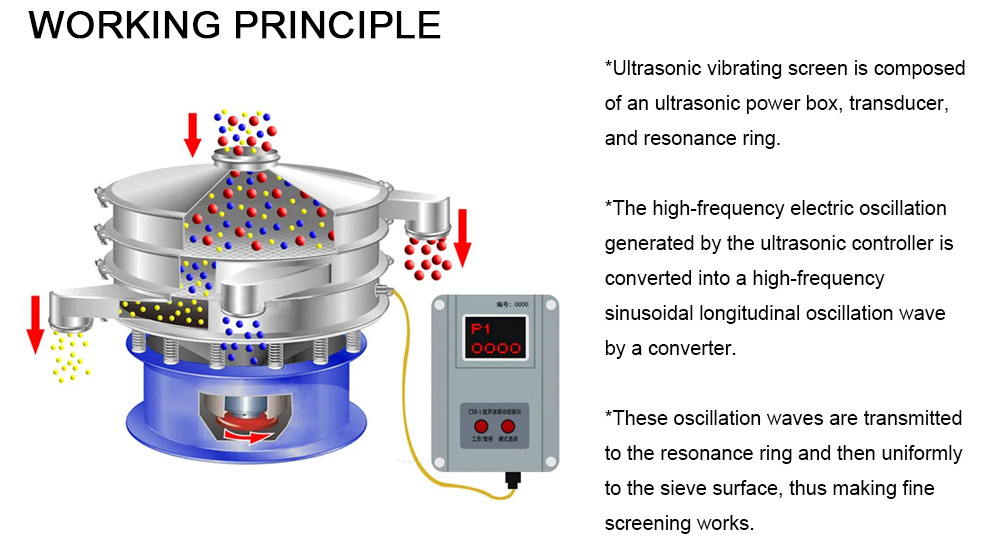

The ultrasonic vibrating screen is a high-frequency vibrating screen with features of high stability, no signal attenuation, and automatic frequency tracking. It adopt unique intelligent ultrasonic vibration signal generator is used to change the incompatibility and non-adjustability of the original single frequency band, realize the organic combination of ultrasonic and vibrating screen, and effectively solve the problem of static agglomeration and strong adsorption material screening .The ultrasonic waves are used to prevent blinding and blockage of the screen mesh, improving the screening accuracy, this technology is commonly used in industries such as pharmaceuticals, chemical, and food processing for precise.

PRODUCT SPECIFICATIONS

|

Model

|

Power

(kw)

|

Effective diameter for sieve surface

|

Packing Size

(MM)

|

Layer(s)

|

|

SYC-600

|

0.25

|

Φ600 mm

|

800×800×680

|

1-5

|

|

SYC-800

|

0.55

|

Φ800 mm

|

900×900×780

|

|

|

SYC-1000

|

0.75

|

Φ970 mm

|

1160×1160×880

|

|

|

SYC-1200

|

1.1

|

Φ1170 mm

|

1360×1360×980

|

|

|

SYC-1500

|

1.5

|

Φ1470 mm

|

1850×1850×1130

|

|

|

SYC-1800

|

2.2

|

Φ1770 mm

|

2200×2200×1360

|

|

* Chemical industry: resin pigment, calcium carbonate, decorative coatings, medicine, grease, paint, palette, etc.

* Abrasive material and ceramic industry: building sand, mica, alumina, silica sand, abrasive, refractory material, slurry, etc.

* Food industry: sugar, salt, alkali, flour powder, nut powder, whey protein powder, maltodextrin, flavors, sucralose, xanthan gum, soy lecithin ,farina, gourmet powder, starch, milk powder, yeast powder, pollen, food additive, bean milk, juice, etc.

* Paper-making industry:coated slurry, exhaust liquid, paper making liquid and waste water reclamation, etc.

* Metallurgy and mining industry: quartz sand, sand, ore, titanium oxide, zinc oxide, etc.

* Mechanical industry: casting sand, charcoal, grafito, powder metallurgy, electromagnetic material and metal powder, etcve material.

FAQ

1). MOQ require of the Ultrasonic Automatic Vibrating Screen?

Our MOQ is 1 set. (If you need the spare parts, it is also ok).

2). Payment method?

Usually, we accept T/T, Western Union, LC and others, we can't accept D/P, D/A

3). How to guarantee the vibrating sieves shaker quality?

If any machine quality problems, we accept return cargos. Our warranty is 12 months, promise your 0 risks purchasing.

4)How to choose vibrating screen separator? [Please provide the information as you could.]

1, Handling material? Bulk density?

2, Would you like grading size or dust-removal?

3, Production Capacity per hour (KG/H)?

4, How many Layers do you need? Mesh size of each layer?

Hot Searches