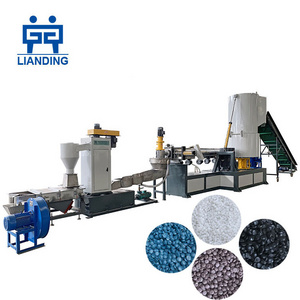

Double Stage Design

Mother Extruder

and Baby Extruder

Cold Cutting pelletizing way

Suitable for hard plastic flakes

Easy to operate

High Capacity