- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Current:

-

50-60HZ

-

Dimensions:

-

2000*2000*2000

-

Use:

-

Stainless Steel + Aluminum + Copper + Other

-

Feature:

-

ultra-low splash

Quick Details

-

Marketing Type:

-

hot product

-

Place of Origin:

-

Guangdong, China

-

Weight (KG):

-

270

-

Voltage:

-

380V

-

Current:

-

50-60HZ

-

Dimensions:

-

2000*2000*2000

-

Use:

-

Stainless Steel + Aluminum + Copper + Other

-

Feature:

-

ultra-low splash

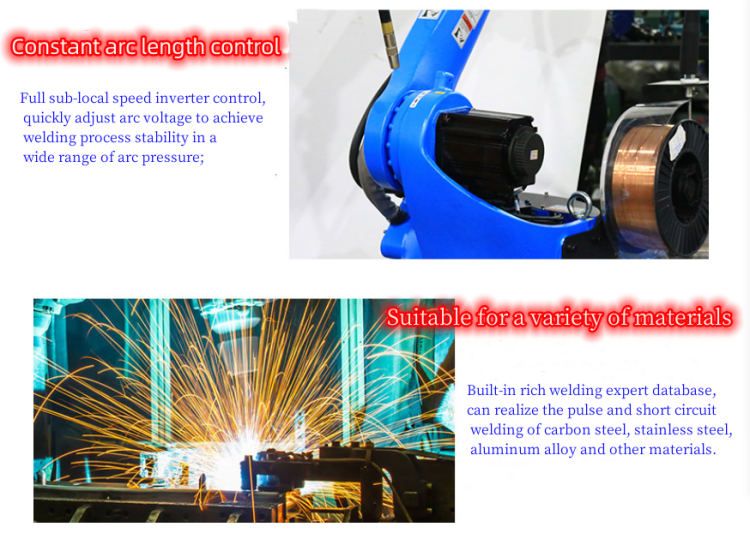

Products Description

1. Fast movement of the robot: the beat is effectively raised and

the transition is natural

.

2. Sheet technology in the arc welding software package: small line segment acceleration, flight arc lifting to effectively improve the beat, wire withdrawal function to effectively improve the success rate of arc lifting, fish scale welding can weld thinner plates.

3.The robot and welder communicate with each other in full digital mode, which is fast and stable.

4.DC, sheet, ultra-low splash: Both CO2 and mixture can be welded with

ultra-low splash

Smooth short circuit transition: the arc is softer, there is tension, and the molding is more beautiful

5. Very high clearance tolerance: high clearance tolerance for errors of workpiece group pairs

6. Feed machine encoder feedback control: can adjust quickly when arc fluctuation occurs

7.Optional fish scale welding function: intermittent dimension arc to reduce spatter, and speed up

Built-in search function: no need to add search hardware

Techincal parameters

|

6 axis robot welding machine |

||

| Model | RH14-10-W | |

| Number of axis | 6 | |

| Payload (kg) | 10 | |

| Reach (mm) | 1454 | |

| Repeatability (mm) | ± 0.05 | |

| Protection class | IP54 | |

| Mounting | Floor and ceiling | |

| Weight (kg) | 170 | |

| Application | Welding | |

| Advantages | Compact structure, high speed, high precision, easy operation. | |

| Max. speed (°/s) | axis 1 | 169 |

| axis 2 | 169 | |

| axis 3 | 169 | |

| axis 4 | 301 | |

| axis 5 | 220 | |

| axis 6 | 743 | |

| Working range (°) | axis 1 | -167-167 |

| axis 2 | -155-90 | |

| axis 3 | -175-240 | |

| axis 4 | -190-190 | |

| axis 5 | -105-130 | |

| axis 6 | -210-210 | |

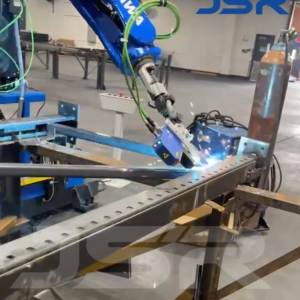

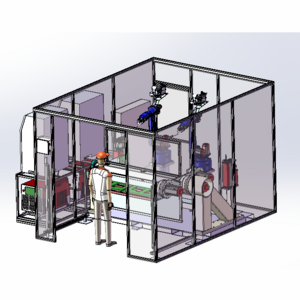

Successful case

Work site

Welding effect