- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

LM

-

Pulse Width:

-

Adjustable

-

Wavelength:

-

1070nm

-

Dimensions:

-

136*71*123CM

-

Weight (KG):

-

225 KG

-

Applicable Industries:

-

metal processing, metal welding, metal cutting, metal cleaning, metal welding seam cleaning

-

Marketing Type:

-

New Product 2024

-

Core Components:

-

laser generator

-

power:

-

1000w/1500w/2000w/3000w

-

Scan width:

-

50-120mm

-

Cooling method:

-

S&A Water Chiller Cooling

-

Cleaning materials:

-

rust, oil, paint, oxide layers, welds

-

Cleaning Process:

-

Laser Non-contact Laser Cleaning

-

Standard cable length:

-

20M

-

Voltage:

-

380v

-

Processing material:

-

Metal Stainless Steel Carbon Steel

Quick Details

-

Max. Output Power:

-

3000w

-

Usage:

-

laser welding

-

Laser Source Brand:

-

BWT/MAX

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

LM

-

Pulse Width:

-

Adjustable

-

Wavelength:

-

1070nm

-

Dimensions:

-

136*71*123CM

-

Weight (KG):

-

225 KG

-

Applicable Industries:

-

metal processing, metal welding, metal cutting, metal cleaning, metal welding seam cleaning

-

Marketing Type:

-

New Product 2024

-

Core Components:

-

laser generator

-

power:

-

1000w/1500w/2000w/3000w

-

Scan width:

-

50-120mm

-

Cooling method:

-

S&A Water Chiller Cooling

-

Cleaning materials:

-

rust, oil, paint, oxide layers, welds

-

Cleaning Process:

-

Laser Non-contact Laser Cleaning

-

Standard cable length:

-

20M

-

Voltage:

-

380v

-

Processing material:

-

Metal Stainless Steel Carbon Steel

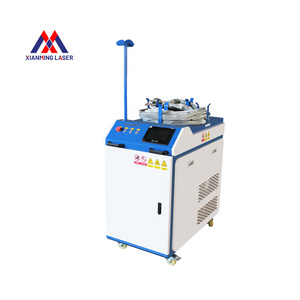

3000W handheld portable Laser Welding Cleaning Cutting Machine

4 in 1 Mini Portable Fiber Laser Welding Cleaning Cutting Machine

The 4 in 1 laser welding cleaning cutting machine can not only clean the metal surface contaminants, but also weld and cut various metal materials. It is a multi-functional laser equipment. And it has three modes of welding cleaning and cutting, which can be flexibly switched.

Laser power: 3000W

Laser source brand: Raycus/Jpt/Max/Reci(optional)

Fiber laser width: 10m (optional)

Cooling system: water cooling

Air system: air compressor

Application: thin stainless steel plates, carbon steel plates, galvanized sheets, ect

Features:

1.High efficiency.

2.Simple interface operation.

3.Hand-held design is easy to carry.

4. protect mirrors Nozzles

The 4 in 1 laser welding cleaning cutting machine can not only clean the metal surface contaminants, but also weld and cut various metal materials. It is a multi-functional laser equipment. And it has three modes of welding cleaning and cutting, which can be flexibly switched.

Laser power: 3000W

Laser source brand: Raycus/Jpt/Max/Reci(optional)

Fiber laser width: 10m (optional)

Cooling system: water cooling

Air system: air compressor

Application: thin stainless steel plates, carbon steel plates, galvanized sheets, ect

Features:

1.High efficiency.

2.Simple interface operation.

3.Hand-held design is easy to carry.

4. protect mirrors Nozzles

Bulk purchases to obtain greater support from suppliers, lower purchase costs for the same product, and better after-sales policies.

Product Description

Fiber Laser welding cuttting cleaning Machine 3000W

The latest 3000W small cabinet is easier to move, saves space and saves shipping costs.The laser cleaning machine can efficiently remove resin, oil stains, stains, dirt, rust, coating, plating, and paint on the surface of the workpiece, meeting the cleaning requirements of complex shapes and fine positioning in the industrial processing field, achieving a cleaner cleaning effect with higher cleanliness.

Touch Control System

Water-Cooling System

As a new cleaning technology, laser cleaning has many advantages, such as environmental protection and high efficiency. It is one of the main development directions of laser technology today, and has a broad application prospect. It has been well applied in aerospace, shipbuilding, rail transit, automobile manufacturing, steel manufacturing, electronic industry, medical care and cultural relics restoration.

Aerospace industry

Laser cleaning of aluminum alloy before and after welding; Laser cleaning of titanium alloy before and after welding; Laser cleaning for aircraft radar layer repair Shipbuilding industry

Laser cleaning before and after welding in shipbuilding; Laser cleaning of the surface before painting; Ship maintenance

accomplishment

Rail transit industry

Laser cleaning for stainless steel train manufacturing; Laser cleaning for aluminum alloy train manufacturing; Maintenance and

accomplishment of rail transit equipment Laser cleaning

Automobile manufacturing industry

Laser cleaning of galvanized sheet before welding; Laser cleaning of aluminum alloy before and after welding

Steel manufacturing industry

Laser derusting of steel surface; Laser Derusting of Cold Rolled Sheet Surface

Electronics industry

Cleaning of oxide layer of electronic board; Cleaning of electronic component joints before welding

Advantages

Break the limits of the workbench Helping you to produce efficiently

Break the limits of the workbench Helping you to produce efficiently

1. Lightweight shape, ergonomic design, comfortable grip,easy to operate, with safety alarm, automatic light lock after removing the workpiece, high safety.

2. Equipped with a nozzle assembly and a variety of angular copper nozzles to meet different production needs.

3. The internal design is dexterous, with good interactive control system, accurate positioning and flexible alignment

4. Suitable for a wide range of metals or alloys, for welding and cutting between a variety of shaped materials, for media-free cleaning, manual focus, and for cleaning of fitted surfaces

Specification

|

Machine model

|

Hand-held fiber cleaning machine

|

|

Laser source

|

MAX/JPT/Raycus

|

|

laser power

|

1000W/1500W/2000W/3000W

|

|

laser wave length

|

1070 NM

|

|

Uptime

|

24 hours

|

|

operate mode

|

continuation/ modulate

|

|

Welding speed range

|

0~120 mm/s

|

|

Laser pulse width

|

0.1-20ms

|

|

Cooling chiller

|

Industrial water chiller

|

|

Working environment temperature range

|

15~35 ℃

|

|

Humidity range of working environment

|

< 70% No condensation

|

|

Welding thickness recommendations

|

0.5-3mm

|

|

Welding gap requirements

|

≤0.5mm

|

|

Working voltage

|

220 V

|

|

Dimensions

|

107×65×76cm

|

|

Weight

|

150kg

|

Samples

Laser Cleaning Machine can be used to remove the defective layer on the surface of metal or glass and remove paint quickly. It can not only remove all the paint layers, but also remove the surface paint layer by layer; quickly remove rust and various oxides on the metal surface; remove grease, resin, glue, Molds, stains, production slag; metal surface roughening; rust and oil removal of automobile parts before welding, and cleaning of oxides and stains after welding; mold cleaning, such as tire molds, electronic molds, food molds; production and processing of precision parts Post-oil pollution removal; rapid cleaning of nuclear power component maintenance; oxide treatment, paint removal, and rust removal during the production or maintenance of aerospace weapons and ships; metal surface cleaning in small spaces; cultural relic cleaning, rock cleaning, and building exterior surface cleaning.

Application areas

Partial certificate display

We have passed the international certifications such as CE certification, ISO9001 quality management system certification, Alibaba SGS enterprise certification and design patents.Strictly control all aspects of incoming materials, processing, assembly, commissioning, testing, packaging and shipping to ensure the performance and quality of laser products. Laser Max, a high-tech enterprise specializing in R&D, production and sales, has more than 10 years of experience in the laser industry. Its products mainly cover fiber laser cutting machine, laser engraving machine,laser marking machine,and laser welding machine. Our factory covers an area of 8000 square meters, and contains nearly 100 employees, which maximally shorten product cycle time and guarantee the delivery of products. Our products are exported to more than 160 countries and regions around Asia, Europe, Africa and Oceania. In addition, we have more than 10 professional after-sales personnel, providing 24-hour online and offline technical

services in 12 languages. In a word, we are committed to helping customers improve their economic efficiency and providing comprehensive laser application solutions for users around the world.

services in 12 languages. In a word, we are committed to helping customers improve their economic efficiency and providing comprehensive laser application solutions for users around the world.

COMPANY PROFILE

Laser Max found in 2013,is one high-tech enterprise with focus on developing,manufacturing and servicing for laser equipment and system

2013 Jinan was established

2015 developed rapidly , product sales exceeded 800 sets

2016 Laser Cutting Division was established

2018 over 2000 sets of machines been sold, beeing one of the well-known manufacturers of laser equipment in the world

2020 laser cutting factory which size over 8000 square meters was established in Jinan. Sales keeping growth rapidly, sales reach 120 million RMB.

2021, independently developed and produced the first 12,000 watt high-power laser cutting machine

2022, more than 10sets 12000W high-power laser cutting machines and 5sets 20000w laser cutting machines were delivered Laser Max with a decade of cumulative laser equipment design and manufacturing expertise Laser Max focus on laser cutting machine, laser welding machine, laser cleaning machine, laser marking machines, customized and other series of more than 50 kinds of industry specific laser solutions.Having long-term with Unite States,Russia,Mexico,Britain,Germany,Brazil,Korea,Turkey,India,Indonesia,Saudi Arabia and more than 50 countries' company in R&D cooperation

2015 developed rapidly , product sales exceeded 800 sets

2016 Laser Cutting Division was established

2018 over 2000 sets of machines been sold, beeing one of the well-known manufacturers of laser equipment in the world

2020 laser cutting factory which size over 8000 square meters was established in Jinan. Sales keeping growth rapidly, sales reach 120 million RMB.

2021, independently developed and produced the first 12,000 watt high-power laser cutting machine

2022, more than 10sets 12000W high-power laser cutting machines and 5sets 20000w laser cutting machines were delivered Laser Max with a decade of cumulative laser equipment design and manufacturing expertise Laser Max focus on laser cutting machine, laser welding machine, laser cleaning machine, laser marking machines, customized and other series of more than 50 kinds of industry specific laser solutions.Having long-term with Unite States,Russia,Mexico,Britain,Germany,Brazil,Korea,Turkey,India,Indonesia,Saudi Arabia and more than 50 countries' company in R&D cooperation

Bulk purchases to obtain greater support from suppliers, lower purchase costs for the same product, and better after-sales policies

.Laser Max is willing to share our advantages and resources with partners, and warmly welcome to cooperate with us

After-sell Service

What kind of support you can get from LASER MAX?

一.

3 year warranty

,Provide a full range of technical support for life.

二. From monday to sunday 9am to 22pm. Experienced technician to guarantee lifetime online support(by whatsapp /skyper /wechat /email). So there is no need to worry about technical support due to time difference.

三. Support local after-sales service. up to 2022, we have offered onsite to these countries and areas: Canada, Mexico, the United States, Ukraine, Russia, Italy, Poland, Spain, Brazil, Indonesia, India, Turkey, Thailand, Vietnam, Australia,etc..

三. Support local after-sales service. up to 2022, we have offered onsite to these countries and areas: Canada, Mexico, the United States, Ukraine, Russia, Italy, Poland, Spain, Brazil, Indonesia, India, Turkey, Thailand, Vietnam, Australia,etc..

Package & Delivery

1. Cleaning the fiber laser cutting machine.

2. Wrap all the laser cutting machine parts with bubble film and plastic film.

3. Fix the machine with iron frame.

4. Wooden box sealing the fumigated plywood portection is finished.

5. Forklift the packed machine to the container.

6. Choose the optimal routes and transportation mode according to the distance.

2. Wrap all the laser cutting machine parts with bubble film and plastic film.

3. Fix the machine with iron frame.

4. Wooden box sealing the fumigated plywood portection is finished.

5. Forklift the packed machine to the container.

6. Choose the optimal routes and transportation mode according to the distance.

(1)Packaging:

Whole film packaging machine; anti-collision package edge; fumigation-free plywood wooden box and pallets with iron binding belt.

(2)Shipping:We cooperate with the company whose experience in the ocean transportation will guarantee your machine safety. We also provide train transport, especially to Russia, Ukraine and other inland countries.

Whole film packaging machine; anti-collision package edge; fumigation-free plywood wooden box and pallets with iron binding belt.

(2)Shipping:We cooperate with the company whose experience in the ocean transportation will guarantee your machine safety. We also provide train transport, especially to Russia, Ukraine and other inland countries.

FAQ

How to operate the machine ?

We will deliver English manual and video with the machine to you. If you still need our help, please contact us.

How can I get the sample to check you quality ?

If you want to welding sample to check the quality, we can help you do this.Just tell us your needs, when finished the testing, we can send testing video to you, if you need, we also can send welding sample to you.

Does the machine can be customized according to my requirements ?

Yes, we have a strong technical team and have rich experience. Tell us your needs, and we will customize your own solutions

We will deliver English manual and video with the machine to you. If you still need our help, please contact us.

How can I get the sample to check you quality ?

If you want to welding sample to check the quality, we can help you do this.Just tell us your needs, when finished the testing, we can send testing video to you, if you need, we also can send welding sample to you.

Does the machine can be customized according to my requirements ?

Yes, we have a strong technical team and have rich experience. Tell us your needs, and we will customize your own solutions

Hot Searches