Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Application:

-

building materials, chemicals

-

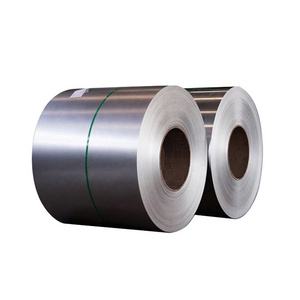

Thickness:

-

0.3-200mm, hot rolled 2.5mm-200mm/cold rolled 0.3mm - 6mm

-

Width:

-

10-3500mm

-

Grade:

-

200 300 400 Series

-

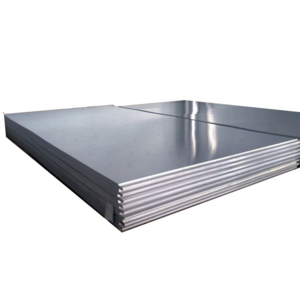

Product name:

-

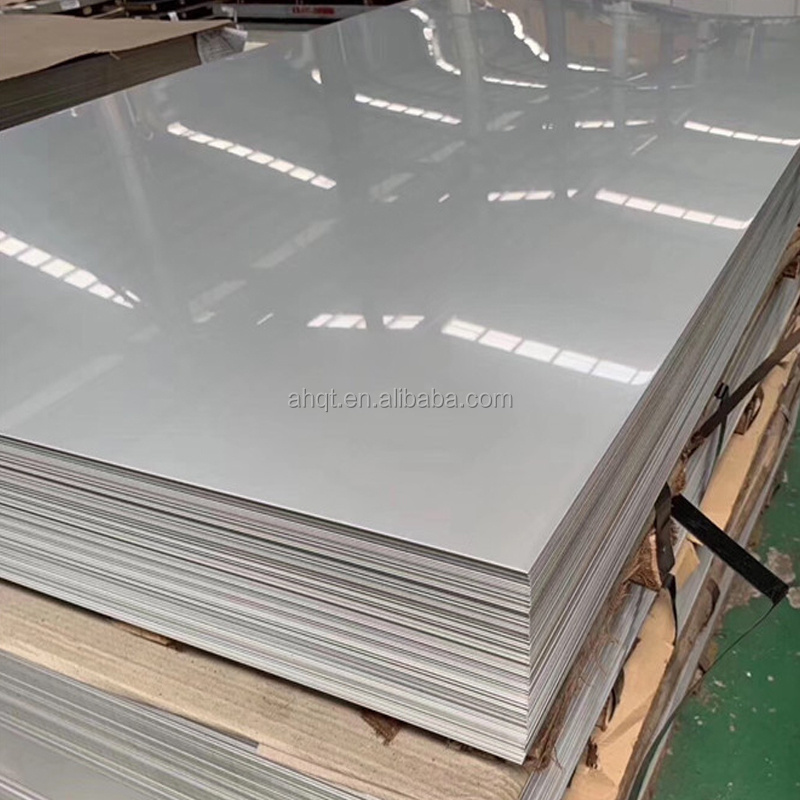

Stainless steel

-

Keyword:

-

304 304l Stainless Steel Plate

-

MOQ:

-

1 Ton

-

Packing:

-

Seaworthy Package

-

surface finish:

-

2B/BA 4K 8K

-

Payment terms:

-

30%T/T Advance + 70% Balance

-

Port:

-

Qingdao/Tianjin

-

width:

-

hot rolled 1000mm-3500mm/cold rolled 10mm - 2000mm

-

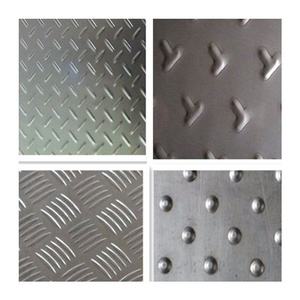

Finish:

-

2B, NO.1, HL, NO.4, 4K, 8K, sandblast, BA

Quick Details

-

Surface Finish:

-

2B/BA 4K 8K

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

BEST STEEL

-

Application:

-

building materials, chemicals

-

Thickness:

-

0.3-200mm, hot rolled 2.5mm-200mm/cold rolled 0.3mm - 6mm

-

Width:

-

10-3500mm

-

Grade:

-

200 300 400 Series

-

Product name:

-

Stainless steel

-

Keyword:

-

304 304l Stainless Steel Plate

-

MOQ:

-

1 Ton

-

Packing:

-

Seaworthy Package

-

surface finish:

-

2B/BA 4K 8K

-

Payment terms:

-

30%T/T Advance + 70% Balance

-

Port:

-

Qingdao/Tianjin

-

width:

-

hot rolled 1000mm-3500mm/cold rolled 10mm - 2000mm

-

Finish:

-

2B, NO.1, HL, NO.4, 4K, 8K, sandblast, BA

|

Standard |

GB,AISI,ASTM,DIN,EN,JIS |

|

Grade |

Stainless steel 304 / 304L / 310S / 316L / 316Ti / 316LN / 317L / 904L / 2205 / 2507 / 32760 / S31254 / XM-19 / S31803 /S32750 / S32205 / F50 / F60 / F55 / F60 / F61 / F65 etc |

|

Monel 400 / Monel K-500 |

|

|

Inconel 600 / Inconel 601 / Inconel 625 / Inconel 617 / Inconel 690 / Inconel 718 / Inconel X-750 |

|

|

Incoloy A-286 / Incoloy 800 / Incoloy 800H / Incoloy 800HT |

|

|

Incoloy 825 / Incoloy 901 / Incoloy 925 / Incoloy 926 |

|

|

Nimonic 75 / Nimonic 80A / Nimonic 90 / Nimonic 105 / Nimonic C263 / L-605 |

|

|

Hastelloy B / Hastelloy B-2 / Hastelloy B-3 / Hastelloy C / Hastelloy C-276 / Hastelloy C-22 |

|

|

Hastelloy C-4 / Hastelloy C-2000 / Hastelloy G-35 / Hastelloy X / Hastelloy N |

|

|

PH stainless steel 15-5PH / 17-4PH / 17-7PH |

|

|

Thickness |

hot rolled 2.5mm-200mm/cold rolled 0.3mm - 6mm |

|

width |

hot rolled 1000mm-3500mm/cold rolled 10mm - 2000mm |

|

Finish |

2B, NO.1, HL, NO.4, 4K, 8K, sandblast, BA |

|

Inspection |

TUV,BV,ABS,LR and so on |

|

Application |

Construction, Chemical, Pharmaceutical & Bio-Medical, Petrochemical & Refinery, Environmental, Food Processing, Aviation, Chemical,Fertilizer, Sewage Disposal, Desalination, Waste Incineration etc. |

|

Processing Service |

Machining : Turning / Milling / Planing / Drilling / Boring / Grinding / Gear Cutting / CNC Machining |

|

Surface Finish |

Definition |

Application |

|

2B |

Finished by heat treatment, picking, or equivalent cold rolling, followed by skin pass to obtain adequate luster surface. |

With a bright and smooth surface, easy for further grinding to obtain a brighter surface, suitable for medical instruments, milk containers, tableware, and so on. |

|

BA |

Bright heat treatment after cold rolling. |

Structural members .etc.kitchen utensils, cutlery, electric appliances, medical instruments, building decorations, etc. |

|

NO.3/NO.4 |

Polished with No.150-240 abrasives. |

Milky food processing equipment, medical instruments, and building decorations. |

|

HL |

Finished by polishing with abrasives of suitable grain size to obtain continuous streaks. |

Building decorations, such as elevators, escalators, doors, etc. |

|

6K/8K |

A mirror-like reflective surface is obtained by polishing with successively finer abrasives and buffing extensively with all gridlines removed. |

Building entrances, building column casting, elevator wall doors, counters, sculptures, etc. |

What is stainless steel circle?

The corrosion resistance of stainless steel circles mainly depends on their alloy composition (chromium, nickel, titanium, silicon, aluminum, manganese, etc.) and internal structure, which plays a major role in the chromium element. Chromium has high chemical stability, can form a passivation film on the steel surface, make the metal isolated from the outside world, protect the steel plate from oxidation, and increase the corrosion resistance of the steel plate. The corrosion resistance decreases after the passivation film is destroyed

Regarding the quality control of Grand Metal, our products need to go through a series of strict quality control from production to delivery, including thickness testing, tensile testing, tensile testing, surface testing, color difference testing, packaging testing, etc. to ensure Our products are safely delivered to customers.