- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

9800

-

Power (kW):

-

5.5

-

Application:

-

Steel Sheet Grooving

-

Usage:

-

Shape Grooving

-

Type:

-

Vertical

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

KingKong

-

Year:

-

2024

-

Weight (KG):

-

9800

-

Power (kW):

-

5.5

-

Application:

-

Steel Sheet Grooving

-

Usage:

-

Shape Grooving

-

Type:

-

Vertical

|

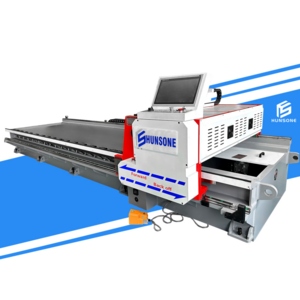

Model

|

MSK-4100*1500(Standard configuration type)

|

|

||

|

Machine range

|

Length 4100mm x Width 1500mm x

Thickness 0.5-6mm

|

Plate parallelism<2mm

|

||

|

System

configuration

|

Control mode

|

4-axis CNC control (X, Y, Z, W) w-axis dual tool holder

|

||

|

|

Monitor

|

15 inch billion image touch screen (optional)

|

||

|

|

Capacity

|

99 sets, 999 channels (capable of 99 cycles)

|

||

|

|

Transmission mode

|

Main motor, ball screw, linear guide rail, gear rack

|

||

|

Clamping

device

|

Hydraulic pressure

|

Optional

|

||

|

Machining

accuracy

|

Main tool holder X-axis positioning

accuracy

|

±0.05mm

|

||

|

|

Rear material Y-axis positioning

accuracy

|

±0.03mm

|

||

|

|

Positioning accuracy of tool holder

Z1 axis

|

±0.02mm

|

||

|

|

Positioning accuracy of tool holder

Z2 axis

|

±0.02mm

|

||

|

Processing

speed

|

Main tool holder X-axis

|

0-90m/min(Stepless speed regulation)

|

||

|

|

Rear stopper Y-axis

|

0-90m/min(Stepless speed regulation)

|

||

|

|

Tool holder Z1, Z2 axis

|

0-20m/min(Stepless speed regulation)

|

||

|

Structural

accuracy

|

Parallelism of workbench

|

±0.03mm

|

||

|

|

Parallelism of knife rest crossbeam

guide rail

|

±0.03mm

|

||

|

|

Parallelism of rear retaining rail

|

±0.03mm

|

||

|

Diameter of

the pressing

cylinder

|

Hydro-cylinder

|

θ30mmx Stroke 32mm

|

||

|

Minimum edge

distance for

grooving

|

|

8mm(Customizable according to customer

requirements)

|

||

|

Overall

dimensions

|

5800mm long * 2100mm wide * 2000mm high

|

|

||

|

Note: The final interpretation rights of the above parameters belong to our company

|

|

|

||

All equipment packaging is wrapped in film, and the film cover is covered again before being loaded into a container for transportation. Some models of equipment can enter and exit the container as a whole, without the need to dismantle any part for loading and unloading goodsAll equipment packaging is wrapped in film, and the film cover is covered again before being loaded into a container for transportation. Some models of equipment can enter and exit the container as a whole, without the need to dismantle any part for loading and unloading goods

Q: How to choose the most suitable model?

A: You can send us the technical requirements for the parts you need to process, and we will recommend the most suitable model to you based on the actual situation, and provide you with a detailed introduction to the advantages and disadvantages of each model.

Q: How to disassemble the equipment during transportation?

A: We will carefully package and secure each device onto the container, and after unloading the equipment, we will provide video guidance for you to assemble the goods. Some models of equipment can be transported as a whole, without the need for assembly after unloading, and can be used directly.

Q: What kind of payment do you accept?

A: Generally, we accept T/T and L/C payment, 30% deposit and 70% payment before delivery.

Q: What is the warranty period of your machine?

A: For conventional machines, our warranty period is one year. For special non-standard machines, we may provide a 2-3 yearwarranty, but this should be confirmed with our sales team in advance.

A: You can send us the technical requirements for the parts you need to process, and we will recommend the most suitable model to you based on the actual situation, and provide you with a detailed introduction to the advantages and disadvantages of each model.

Q: How to disassemble the equipment during transportation?

A: We will carefully package and secure each device onto the container, and after unloading the equipment, we will provide video guidance for you to assemble the goods. Some models of equipment can be transported as a whole, without the need for assembly after unloading, and can be used directly.

Q: What kind of payment do you accept?

A: Generally, we accept T/T and L/C payment, 30% deposit and 70% payment before delivery.

Q: What is the warranty period of your machine?

A: For conventional machines, our warranty period is one year. For special non-standard machines, we may provide a 2-3 yearwarranty, but this should be confirmed with our sales team in advance.

Hot Searches