- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

60*30*60cm

-

Weight:

-

80 KG

-

Output product name:

-

Nut Butter Or Paste

-

Product name:

-

Colloid mill

-

Advantage:

-

High Effieciency

-

Application:

-

Food Industry

-

Certification:

-

CE ISO

-

Raw material of machine:

-

304 stainless steel

-

Function:

-

Grinding Processing Making

-

Capacity:

-

10-1500kg

Quick Details

-

Place of Origin:

-

Henan, China

-

Voltage:

-

220/380V, 220/380V

-

Power:

-

2.2KW-45KW, 2.2 kw - 45 kw

-

Dimension(L*W*H):

-

60*30*60cm

-

Weight:

-

80 KG

-

Output product name:

-

Nut Butter Or Paste

-

Product name:

-

Colloid mill

-

Advantage:

-

High Effieciency

-

Application:

-

Food Industry

-

Certification:

-

CE ISO

-

Raw material of machine:

-

304 stainless steel

-

Function:

-

Grinding Processing Making

-

Capacity:

-

10-1500kg

Product Description

Introduction of Colloid Mill

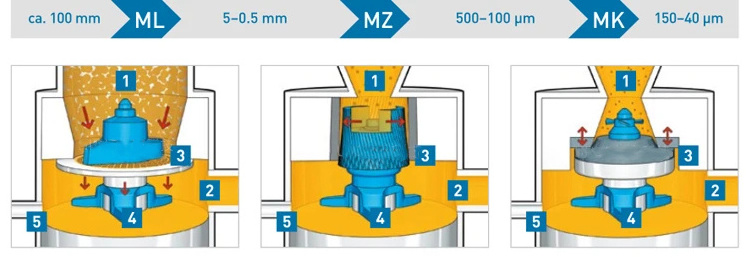

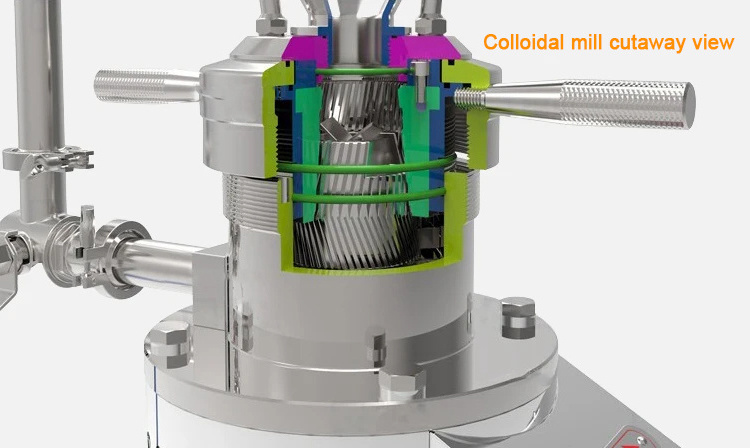

A colloid mill reduces the particle size of a solid by applying shearing, grinding and high speed mixing. Grinding is accomplished by the relative motion of two tooth profile inclines (one rotating at a high speed, the other being still).

Colloid mill is the ideal equipment for wet grinding at present, Materials between the tooth profile inclines are effectively dispersed, pulverized and homogenized under high levels of shearing force, friction, high-frequency vibration and other forces.

1.

A pair of conical rotating teeth in the colloid mill and fixed teeth do relative movement, the material through the gap between fixed and rotating teeth, subjected to shear force, friction.

2.

Fine ultrafine particle crushing efficiency is high, using shear, grinding and high-speed stirring force, crushing and grinding rely on the relative movement of the grinding disk tooth bevel.

3.

Colloid mill is the ideal equipment for wet grinding at present. Under the action of complex forces such as high-frequency vibration and high-speed vortex, the material is ground, emulsified,crushed, mixed, dispersed and homogenized.

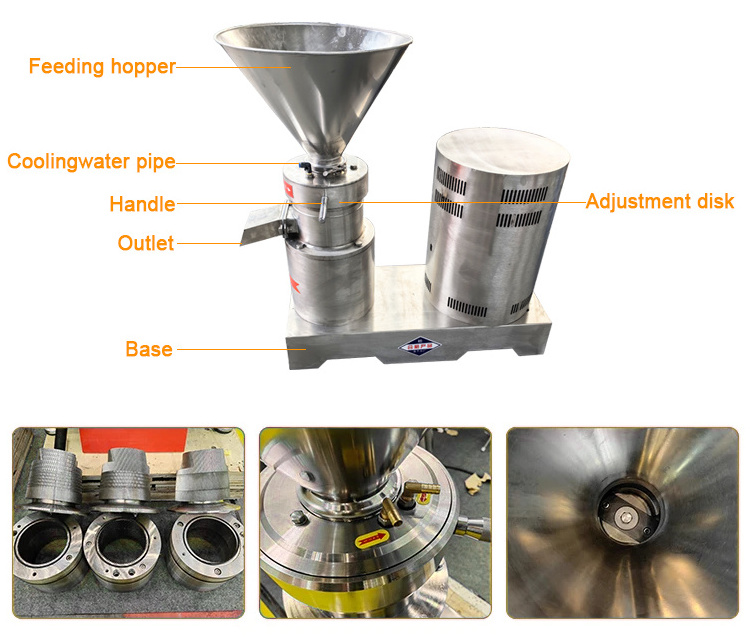

Hopper

304, 316L stainless steel material, sanitary and long life, widely used in industry, food,and other industries. Customized size.

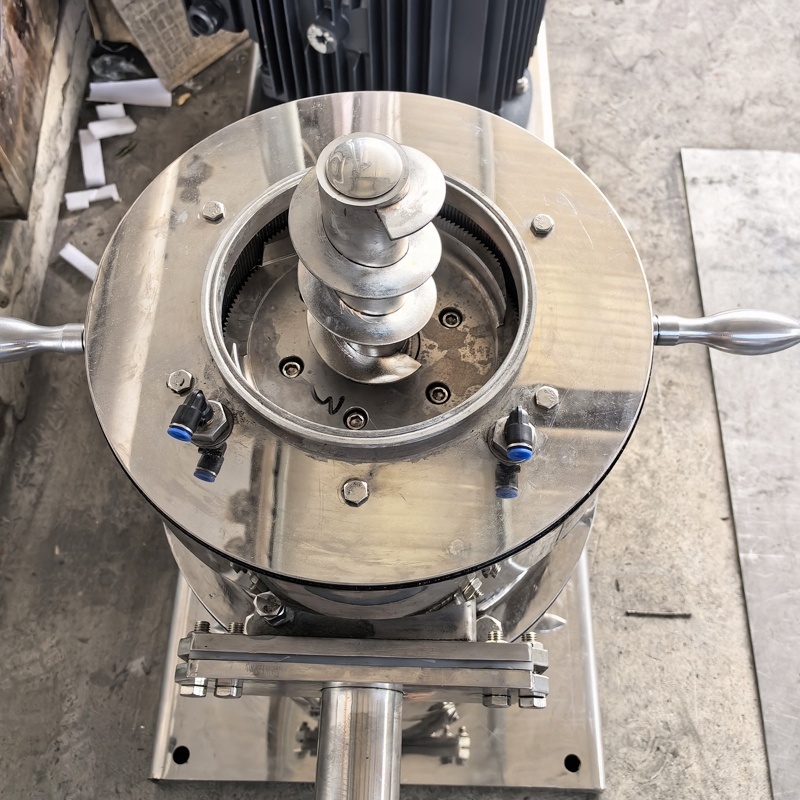

Teeth

High precision stainless steel mill, tight gear structure, 2800r/min speed grinding material in a moment.

Adjusting disk

Adjust fineness according to demand, about 2~40μm, easy to operate.

Outlet 1: Circulating pipe

Suitable for low-viscosity materials that need reflux or grinding,such as fruit juice,soy milk,etc.

Outlet 2: Square

Suitable for high and medium viscosity materials that don't need reflux or grinding,such as peanut butter,chilli sauce,etc.

Product Paramenters

|

Model

|

Power

|

Size

|

Capacity

|

Weight

|

|

50

|

2.2kw

|

600*300*600mm

|

10kg/h

|

80KG

|

|

80

|

5.5kw

7.5kw

|

800*350*800mm

|

150-200kg/h

|

130KG

|

|

130

|

7.5kw

11kw

|

1000*450*900mm

|

200-300kg/h

|

230KG

|

|

160

|

18.5kw

|

1300*550*1100mm

|

400kg/h

|

300KG

|

|

180

|

22kw

|

1500*600*1450mm

|

500-600kg/h

|

380KG

|

|

240

|

37kw

|

1600*650*1450mm

|

1000kg/h

|

550KG

|

|

300

|

45kw

|

1650*750*1450mm

|

1500kg/h

|

800KG

|

Product Application

Product Show

About Us

Henan vibrate Machinery is a production of food, chemical equipment enterprises, located in Henan Xinxiang City. We design custom solutions for the production, washing, cutting, meat processing, packaging and filling of vegetables, spices, meat, liquids, powders and pellets in many industries such as food, pharmaceutical, plastics, chemical, etc. Our main products include: packaging machines, filling machines, cleaning machines, cutting machines, meat processing machines and related products. the company has passed iso9001 quality management system certification and SGS certification, and all products have passed CE certification. At present, the products have been exported to 96 countries and regions. We also have in-depth cooperation with local agents in key markets such as Indonesia, Malaysia, Singapore, Thailand, India, Vietnam, Brazil, Australia, France, United Kingdom, Hungary, etc., to provide localized after-sales service and technical support.

Customer

Packing & Shipping

FAQ

Q: 1. Are you a manufacturer, trading company or third party?

A: We are a manufacturer, located in the high-tech zone of Xinxiang City, Henan Province, China. You are warmly welcome to visit our company.

Q:2. What is your minimum order quantity and can you send me samples?

A: Our MOQ is 1 set, because our products are mechanical equipments, so it is difficult to send you samples, if you have any questions about the products, please feel free to contact us for more details, we will be happy to provide you with more information, such as specifications, videos and so on.

Q:3. How does your factory perform quality control?

A:(1) All raw materials we use are environmentally friendly.

(2) Skilled workers pay attention to every detail during production and packaging.

(3) The quality control department specializes in the quality of each process.36 Over the years, we continue to introduce advanced technology and provide high quality products, and our products are also widely exported to many countries, such as Russia, Middle East, Africa, Southeast Asia, and the European Union, and we have won a high reputation among our customers.

Q: 4. What is the delivery time of your machines?

A: Generally speaking, the delivery period of our machines is about 30 days, and the customized machines will be delivered according to the negotiation with customers.

Q: 5. How about after-sales service?

A:(1) TM is online 24 hours a day, also can be contacted by email, skype, MSN, whatsapp etc.

(2) Problem solving by video/picture.

(3) One year warranty for spare parts replacement. If you encounter any other problems, please feel free to contact us. If you meet any other questions, please feel free to contact us. click here.

Hot Searches