- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

ZTRFM

-

Product name:

-

roll slitting machine

-

Decoiler Type:

-

hydraulic decoiler

-

line speed:

-

0-60m/min

-

Cutting thickness:

-

0.5-2.0mm

-

width:

-

500-1500(Max)

-

diagonal tolerance:

-

≤±1mm/2000mm

-

length tolerance:

-

≤±0.5mm/2000mm

-

Type:

-

Shearing Machines

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Certification:

-

CE ISO

Quick Details

-

Weight (KG):

-

7000

-

Core Components:

-

PLC, Gear

-

Place of Origin:

-

Hebei,China

-

Brand Name:

-

ZTRFM

-

Product name:

-

roll slitting machine

-

Decoiler Type:

-

hydraulic decoiler

-

line speed:

-

0-60m/min

-

Cutting thickness:

-

0.5-2.0mm

-

width:

-

500-1500(Max)

-

diagonal tolerance:

-

≤±1mm/2000mm

-

length tolerance:

-

≤±0.5mm/2000mm

-

Type:

-

Shearing Machines

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Certification:

-

CE ISO

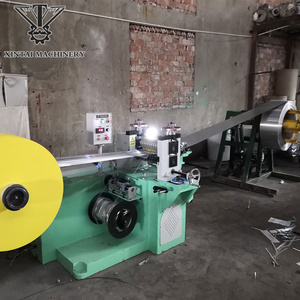

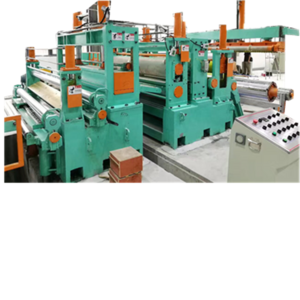

ZTRFM Steel coil slitting machine steel slitting line metal slitting cutting machine

A slitting machine consists of

three main parts

;

the unwind, the slitter and the rewind

. By feeding a large roll of your chosen material through the slitter’s unwind, your material will then unwind and

be slit into various widths

, before being rewound into cores of various widths.

Working flow as below:

|

ZTRFM Steel coil slitting machine steel slitting line metal slitting cutting machine

|

|

|

|

Formed Material

|

PPGI,GI,AI,carbon steel and others

|

|

|

Material Thickness

|

0.5-2.0mm

|

|

|

width of cutting

|

500mm-1500mm(Max)

|

|

|

diameter of leveling rollers

|

65mm

|

|

|

distance of leveling rollers

|

70mm

|

|

|

material of leveling roller

|

GCr15

|

|

|

diagonal tolerance

|

≤±1mm/2000mm

|

|

|

length tolerance

|

≤±0.5mm/2000mm

|

|

|

power

|

380V/50Hz/3Ph

|

|

|

line speed

|

0-60m/min

|

|

|

capacity

|

around 100Kw

|

|

Hydraulic decoiler

Pre-leveling machine

It is composed of two rows leveling roller, two rows middle supporting roller, 2 groups of supporting rollers, driving device, 2 pinch rollers and frame. Each roller both of ends drive with roller pin bearing, the working rollers can be adjusted the gap electrically which is controlled by 2 hand wheels to ensure the leveling quality.

It can straighten the rough plate and guide strip right after entering the process.

High speed Cutter

2. The precious of the width: ±1mm

3. The speed of slitting: 50m/min

4. The width can be change.

5. Material of the slitting: Cr12MoV.

Hardness of slitting blade: HRC5860.

6. slitting: 2~3mm 6 lines.

7. quantity of blades: 10 sets .

8. Width of side scrap: 3-15mm

9. The precious of side scrap: ±0.5mm

10. Quantity of side scrap: 2 strips

Recoiler

Advantage:

Designed with the seamless expand and shrink structure and clip-mouth so that when the strip heads insert into the clip-mouth, it will close automatically and start winding.

PLC control system

2. Control panel: Button-type switch and touch screen

3. PLC : KAUTO

4.

Touch screen:

WEINVIEW (TAIWAN)

5. Frequency converter: DELTA

5. Frequency converter: DELTA

CE(

NO.OP180719.CZIDC95

)

ISO 9001(No:ZL92090220234630)

Hot Searches