▶ High precision camera recognition

▶ Inkjet marking

▶ Drying and unloading

|

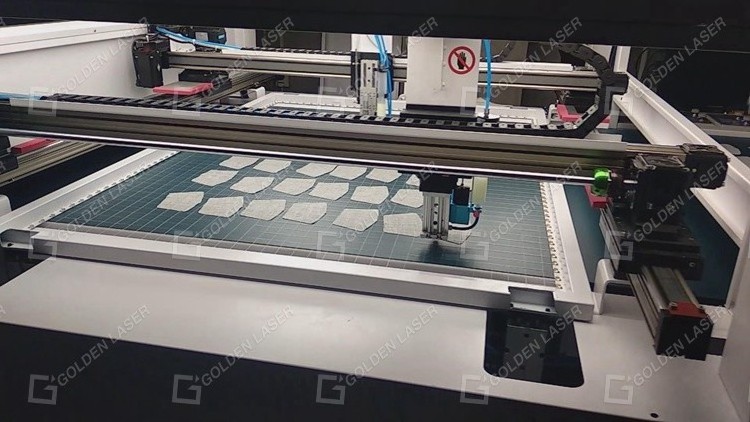

JYBJ-12090LD

Technical Parameters

|

|

|

|

Maximum working speed

|

1,000mm/s

|

|

|

Acceleration

|

12,000mm/s2

|

|

|

Repeating positioning accuracy

|

≤0.05mm

|

|

|

Positioning accuracy

|

≤0.1mm/m

|

|

|

Recognition accuracy

|

≤0.2mm

|

|

|

Working table

|

Rubber belt driving transmission working table

|

|

|

Working table height

|

750mm

|

|

|

Transmission system

|

Synchronous belt module transmission

|

|

|

Control system

|

Servo control system

|

|

|

Vision positioning

|

2.4M pixels industrial camera

|

|

|

Noise

|

≤65Dd

|

|

|

Power supply

|

AC220V±5% 50Hz

|

|

|

Power consumption

|

3KW

|

|

|

Software

|

Golden Laser Vision Positioning Software

|

|

|

Graphic formats supported

|

AI, BMP, PLT, DXF, DST

|

|