- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Raw Wax Tealight Candle Making Machine

-

Function:

-

Normal Candle

-

Advantage:

-

High Efficiency Automatic Working

-

After-sales Service Provided:

-

Online Support

-

MOQ:

-

1 Set

-

Suitable for:

-

Candle Filling Wax Filling

-

Packing:

-

Wooden Case Package

-

Name:

-

Candle Making Machine

-

Keywords:

-

Semi Automatic Small Candle Making Machine

Quick Details

-

Place of Origin:

-

Henan, China

-

Weight:

-

25

-

Product name:

-

Candle Filling Machine

-

Application:

-

Raw Wax Tealight Candle Making Machine

-

Function:

-

Normal Candle

-

Advantage:

-

High Efficiency Automatic Working

-

After-sales Service Provided:

-

Online Support

-

MOQ:

-

1 Set

-

Suitable for:

-

Candle Filling Wax Filling

-

Packing:

-

Wooden Case Package

-

Name:

-

Candle Making Machine

-

Keywords:

-

Semi Automatic Small Candle Making Machine

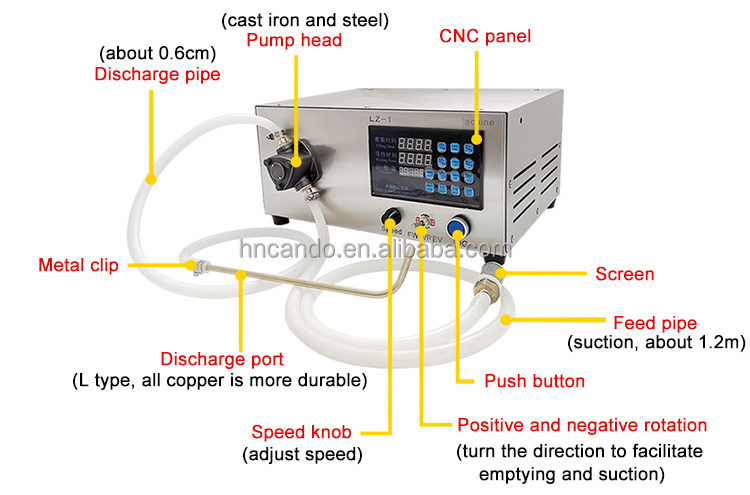

High Speed Candle Making Wax Filling Machine Candle Maker Candle Filling Machine

Products Description

This machine Suitable for filling over 5ml of oily liquids, such as candles, shortening, crystal candles, edible oil, salad oil,etc.If you need to fill candles, melt the candles into liquid in the matching heating bucket, and then follow our instructions tofacilitate filling. The cart can be used for mobile filling.

Product Advantages:

1. The operation panel adopts CNC display, and the filling time range is more flexible, adjustable from 0.01-999.9 seconds

2. Positive and negative rotation function, more convenient wax discharge/emptying

3. The pump head material is more durable with high temperature resistance, simple structure, easy to clean after plugging

4. More customized accessories for candles. There are anti-ejection port (suitable for more than 50ml), pump head heating ring, pipe heating belt, etc., can be purchased, and candle filling is more convenient

|

Model:

|

CD-1

|

CD-2

|

|

Power Supply:

|

AC 220

|

AC 220

|

|

Power:

|

0.15KW

|

0.4KW

|

|

Material quality:

|

stainless steel

|

stainless steel

|

|

Size:

|

410*360*200mm

|

450*380*250mm

|

|

Maximum flow:

|

7000ML/min

|

7000 ML*2/min

|

|

Recommended filling/bottle:

|

10-600ML

|

10-600ML*2

|

Details Images

Installation Instructions

NOTE:

1. Candles need to be heated and melted into liquid before they can be filled.

1. Candles need to be heated and melted into liquid before they can be filled.

2. Before filling the candle, preheat the pipe: cycle with

hot oil

for a few minutes, such as white oil, salad oil, etc

Function : After the hot oil passes through, the pipeline and the pump head are heated together to avoid the wax oil contact with the cold channel after solidification.

Note : LZ models should not be preheated with hot water (refilling candles will cause bubbles and rust inside).

3. After filling the candle: refill it with oil (without heat).

4. Coagulation/clogging treatment:

Method 1: Attach an external heating belt to the pump head, plug in the power supply, and wait for the pump head to heat itself and the candle to melt out. It takes about ten minutes.

Method 2: Manually open the pump head cover, pull out the gear, remove the residual wax, and add a little lubricating oil can be installed back. .

Do not use a hair dryer, heat gun or other tools directly or for a long time to add heat pump head, too high temperature will damage the pump head.

Function : After the hot oil passes through, the pipeline and the pump head are heated together to avoid the wax oil contact with the cold channel after solidification.

Note : LZ models should not be preheated with hot water (refilling candles will cause bubbles and rust inside).

3. After filling the candle: refill it with oil (without heat).

4. Coagulation/clogging treatment:

Method 1: Attach an external heating belt to the pump head, plug in the power supply, and wait for the pump head to heat itself and the candle to melt out. It takes about ten minutes.

Method 2: Manually open the pump head cover, pull out the gear, remove the residual wax, and add a little lubricating oil can be installed back. .

Do not use a hair dryer, heat gun or other tools directly or for a long time to add heat pump head, too high temperature will damage the pump head.

Exhibition

Operating Steps:

1. Filling time adjustment

A. Press the setting key first, the time flashes, and press the increase key 0-9 to set the time required for this bit.

B. Then press the right shift button to position the finger, press the increase button to adjust the time of this bit, and repeat the operation.

C. Press the unit key to move the decimal point back and forth to determine the time unit.

D. Press the Exit key to complete the setting.

2. The intermittent time adjustment is the same as the filling time adjustment.

3. Timer adjustment

A. Press the setting key, the timer flashes, press the increase key 0-9 to adjust the number of

this bit, press the right shift to adjust the number of other bits, and set the required number.

this bit, press the right shift to adjust the number of other bits, and set the required number.

B. Press the mode key, when the light is on, the filling machine will stop working when the specified quantity is filled. When it is not lit, it works continuously and counts continuously.

4. Filling setting Press the filling setting button, and the filling machine starts to work.When the filling reaches the required amount, press the filling setting button. The time displayed on the filling time is the timerequired for filling this amount.

Certifications

FAQ

Q: 1. What are your advantages?

A: Quality and stable products, reasonable prices, good customer service, quick response to any inquiries or problems, on-time delivery.

Q: 2. Are you a factory or a trading company?

A: We are a factory mainly produces the machinery .We have our own professional research team to develop products.using "Self-produced Self-marketing" business model, reducing the cost of intermediate links.

Q: 3. What is the service?

A: 24 hours on line service,your inquiry will be reply quickly.

Q: 4. What should I do if there is some trouble while using?

A: We will supply English manual book and take a video to show how to resolve the problems or dispatch our engineer to your factory.

Q: 5. What's your Minimum Order Quantity?

A: Any order quantity is warmly welcomed.

Q: 6. Does the machine accept customization?

A: Yes, we can customize according to customer's requirements.

Q: 7. What’s the Payment term?

A: 30% deposit, 70 % before delivery or Trade Assurance. L/C,T/T, PayPal and other payment methods if it is convenient for you.

Hot Searches