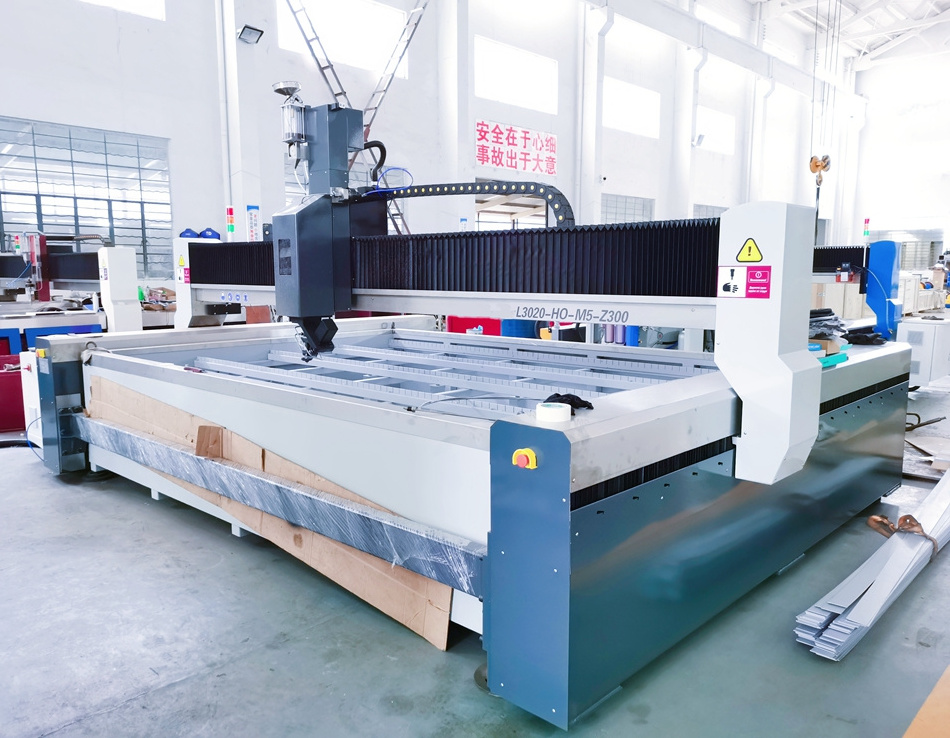

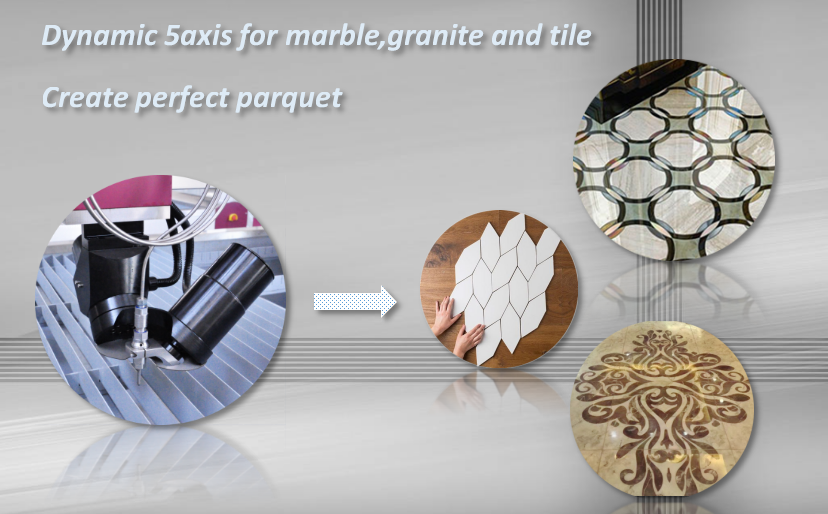

This Dynamic 5 axis water jet cutting machine is specially used to cut marble and granite, it can compensate ±10° cutting angle. It is one kind of bevel cutting machine.

Due to the water jet cutting is a flexible cutting, therefore,there will be a certain degree of inclination on the product cross section after cutting by the traditional 3 axis water jet cutting.In order to ensure the accuracy of vertical cutting section, it must reduce the cutting speed. However, our 5 axis water jet cutting machine can ensure the accuracy of vertical cutting section by compensating the cutting angle, without reducing the cutting speed. So that it can be used for cutting parquet stone, the parquet flooring does not need to be polished again, which can save time and labor.

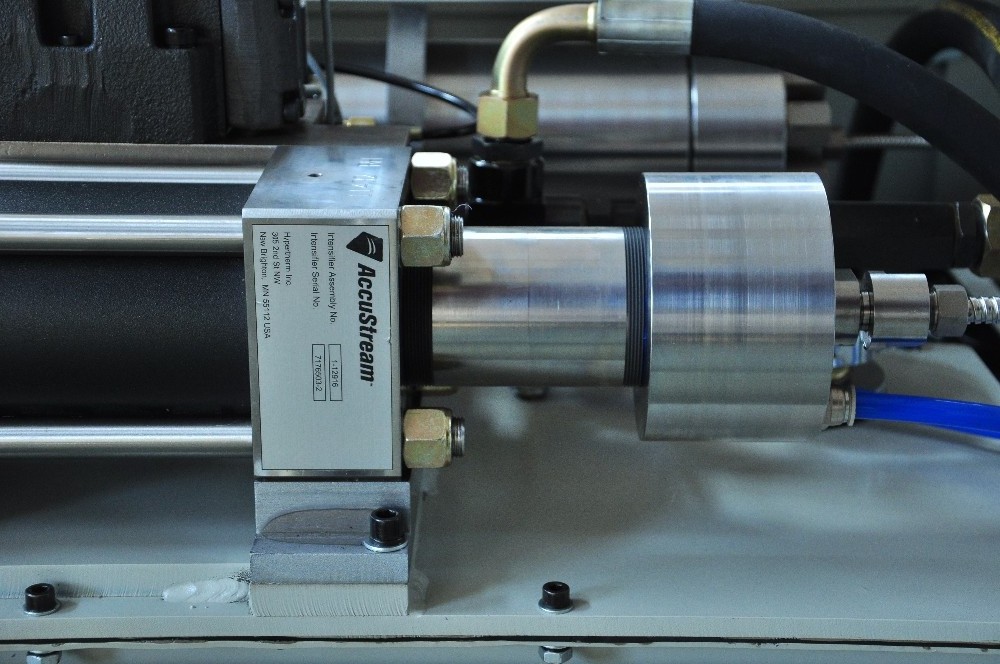

Dynamic 5 axis cutting head X、Y、Z axis for transmission A,B axis for compensation 0°-±10°