- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

3*1*1.6m

-

Weight:

-

1500 KG

-

Place of Origin:

-

Shandong, China

-

Voltage:

-

380v,50hz or according to customer's requirement

-

Power:

-

according to customer's requirement

-

Name:

-

Corn Flakes Production Line

-

Application:

-

Corn Flakes

-

After Warranty Service:

-

Online

-

Function:

-

Multifunctional

-

Material:

-

Stainless Steel Food Grade

-

Feature:

-

Low Energy High Speed

-

Advantage:

-

Easy Operation High Performance

-

Color:

-

Silver

-

MOQ:

-

1 Set

-

Type:

-

Double Screw

Quick Details

-

Machinery Capacity:

-

150kg/h,200kg/h,350kg/h,600kg/h

-

Brand Name:

-

XILANG

-

Year:

-

2024

-

Dimension(L*W*H):

-

3*1*1.6m

-

Weight:

-

1500 KG

-

Place of Origin:

-

Shandong, China

-

Voltage:

-

380v,50hz or according to customer's requirement

-

Power:

-

according to customer's requirement

-

Name:

-

Corn Flakes Production Line

-

Application:

-

Corn Flakes

-

After Warranty Service:

-

Online

-

Function:

-

Multifunctional

-

Material:

-

Stainless Steel Food Grade

-

Feature:

-

Low Energy High Speed

-

Advantage:

-

Easy Operation High Performance

-

Color:

-

Silver

-

MOQ:

-

1 Set

-

Type:

-

Double Screw

Products Description

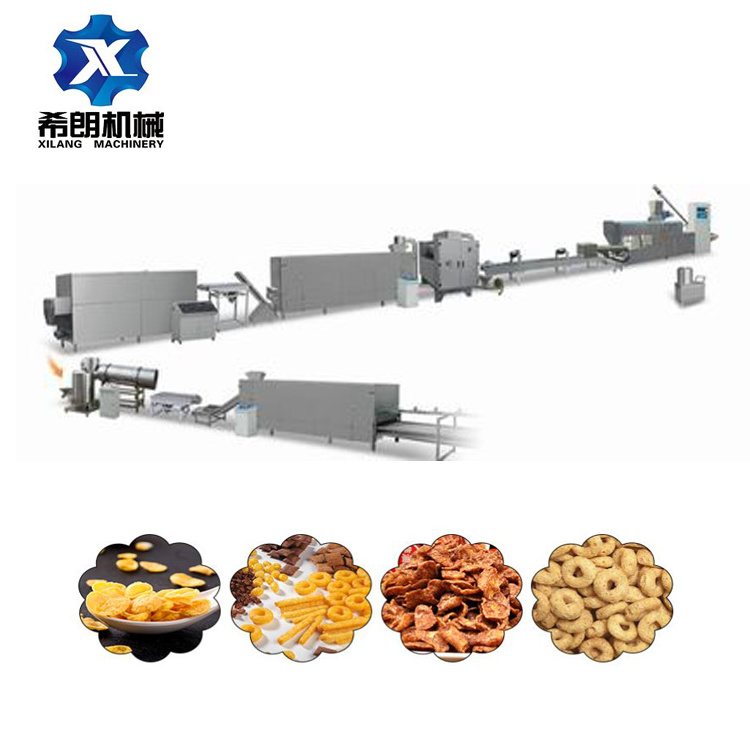

Hot Sale Corn Flakes Production Line Breakfast Cereals Extruder Production Line Breakfast Cereal Making Machine

1 Corn Flakes Making Equipment

corn flakes production line

use cereals as main raw material. Breakfast cereals are made from cereals, which are extruded,pelletized, tableted, dried, baked, coated, dried, and cooled. It can also be processed into rings, granules, flakes and other products after one-time puffing and drying. The product can be mixed with hot coffee and eaten after warming milk, or as a casual snack. The taste is sweet and the taste is excellent.

2 Flow chart of corn flakes making equipment:

Mixing system---Extrusion system---Flaking system---Drying system---Sugar Spraying system ---Drying system---- Packing system

Mixing system---Extrusion system---Flaking system---Drying system---Sugar Spraying system ---Drying system---- Packing system

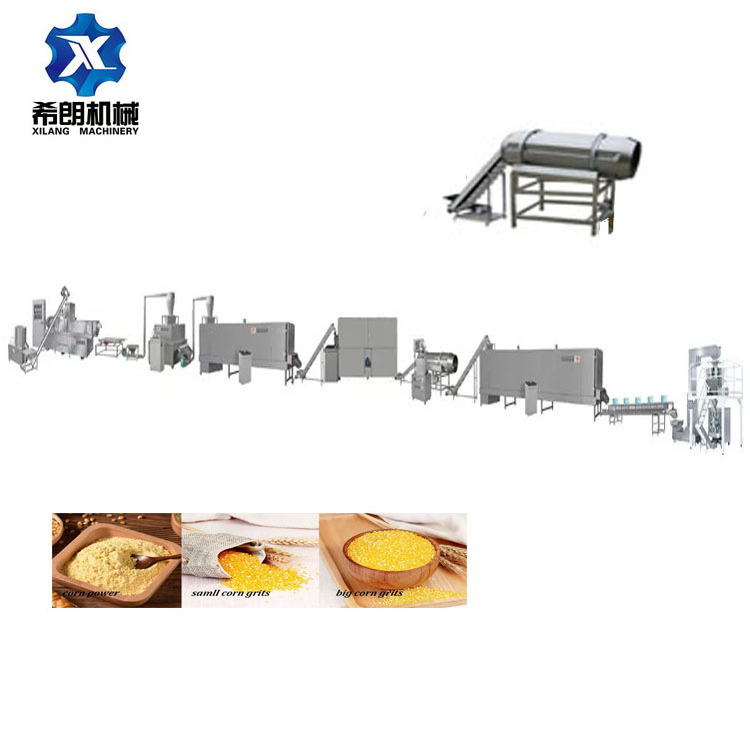

3 Raw Material

: Corn flour, rice flour, wheat flour, soya flour, millet flour, corn grits, and other different grain flours..

4 Voltage in China:

Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers’ Local voltage according to different countries

5 Machines Materials: All the machine are made by stainless steel, this line is with reasonable design and with high automation;the screws are made by alloy steel, with building block system structure and self-cleaning function

5 Machines Materials: All the machine are made by stainless steel, this line is with reasonable design and with high automation;the screws are made by alloy steel, with building block system structure and self-cleaning function

6 The technical specification of breakfast cereal ,corn flakes production line

|

Model

|

65-III twin screw exruder

|

70-II twin screw extruder

|

75 twin screw extruder

|

95 twin screw extruder

|

|

The power of main machine

|

22KW

|

37KW

|

55KW

|

110KW

|

|

Production capacity

|

120-150kg/h

|

180-200kg/h

|

250-350kg/h

|

600-800kg/h

|

|

Appearance size

|

28x1.2x2.0m

|

30x1.5x2.0m

|

38x1.5x2.0m

|

45x1.5x2.0m

|

Details Images

Mixer

This machine can mix raw material(Corn flour, rice flour, wheat flour, soya flour, millet

flour, corn grits and so on),water and other additives.

flour, corn grits and so on),water and other additives.

Extruder

The twin-screw extruder is made of the feeding system, extruding system, cutting system, heating system, transmission system and

controlling system.

controlling system.

Dryer

The dryer include drive motor,drive belt,circulating fan,dehumidification equipment and so on.The moisture of dried material is around

9-10%

9-10%

Hot Searches