- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

GYBF

-

Dimension(L*W*H):

-

1.24x1.07x1.44 m

-

Raw Material:

-

Charcoal Powder / mineral powder

-

Product name:

-

Charcoal Briquette Making Machine

-

Usage:

-

Make Fuel Briquettes

-

Keyword:

-

Coal Forming Machine

-

Power:

-

5.5kw

-

After-sales Service Provided:

-

Online Support

-

Application:

-

Heating Cooking BBQ

-

Finished Products:

-

Charcoal Pieces

-

Package:

-

Wooden Case

-

Diameter of Briquette:

-

5~80mm Customized

Quick Details

-

Weight (KG):

-

750

-

Marketing Type:

-

Hot Product 2023

-

Production Capacity:

-

1-30t/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

GYBF

-

Dimension(L*W*H):

-

1.24x1.07x1.44 m

-

Raw Material:

-

Charcoal Powder / mineral powder

-

Product name:

-

Charcoal Briquette Making Machine

-

Usage:

-

Make Fuel Briquettes

-

Keyword:

-

Coal Forming Machine

-

Power:

-

5.5kw

-

After-sales Service Provided:

-

Online Support

-

Application:

-

Heating Cooking BBQ

-

Finished Products:

-

Charcoal Pieces

-

Package:

-

Wooden Case

-

Diameter of Briquette:

-

5~80mm Customized

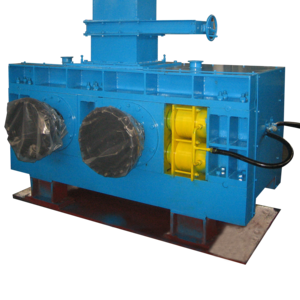

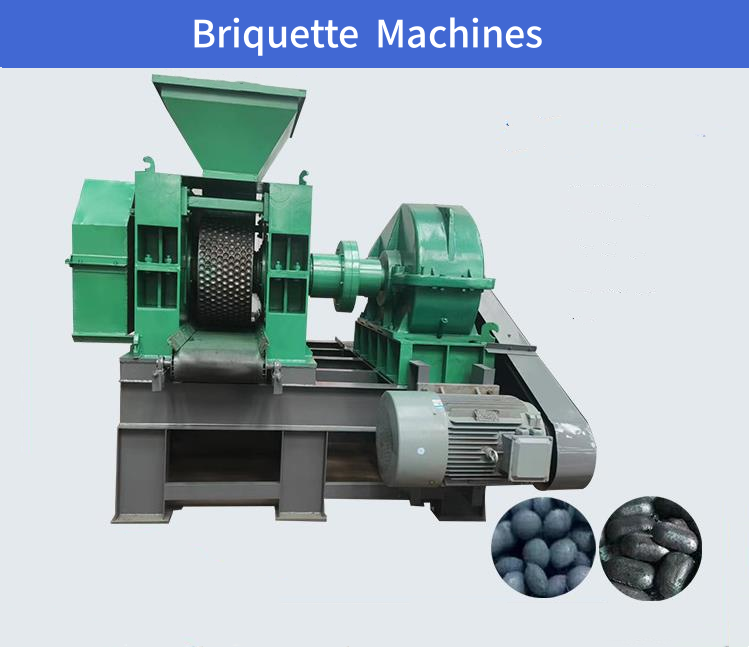

Professional pressing pressure ball machine rice husk coal briquette roller press charcoal briquetting machine

Product Description

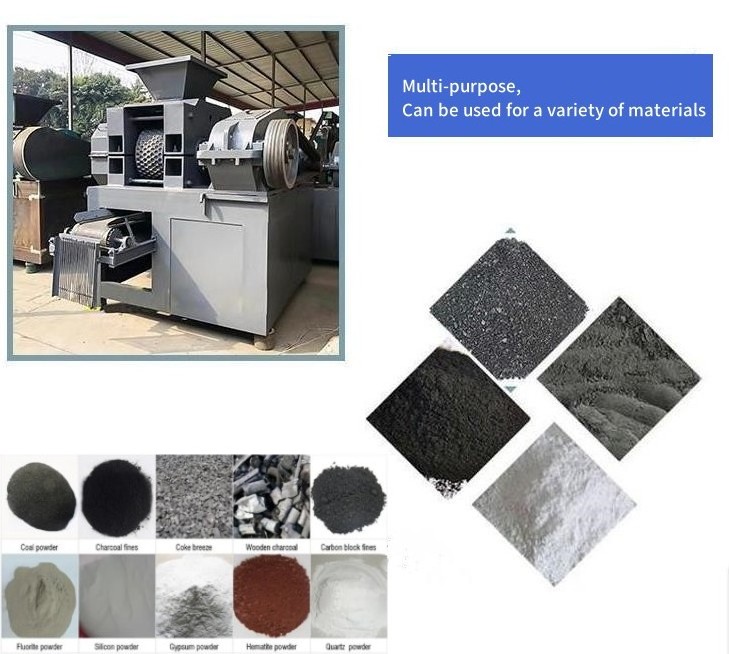

Charcoal coal briquette machines, also called charcoal briquette granulator, is used to process the charcoal powder into charcoal briquettes. Mature technology, stable performance and easy operation, our charcoal powder briquette machine enjoys extensive popularity among clients. With high Calorific value and density, the charcoal briquettes produced by our charcoal powder briquette machine are most suitable for industrial boilers, home heating, barbecue, etc.

Working principle of charcoal ball briquitte machine:

From the storage silo, the material is fed into the molding machine hopper evenly by the quantitative device. Then the regulation board on the hopper make the materal evenly enter into the middle of the roller; the reverse operating roller compress the material and the forming pressure increases gradually, at the centerline of the roll the forming pressure reaches its maximum value, once the material through the line, the molding pressure rapidly decrease so that the material forms into ball shape and smoothly discharge the ball.

Application:

Coal Charcoal ball press briquetting machines and coal briquette machines are widely used in refractory, powder plant, metallurgical, chemical engineering, energy, transportation, heating and other industries.

Product Flow:

Raw materials---crushing---feeding---mixing---briquetting---drying---finished products

Technical parameters of charcoal ball briquitte machine:

Packaging & Shipping

Hot Searches