- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

15000 KG

-

Dimension(L*W*H):

-

10000*25000*3000mm, According to capacity

-

Certification:

-

CE/ISO9001

-

O2 purity:

-

92%~96%

-

O2 Pressure:

-

150Ba,200Bar

-

Technology:

-

Pressure Swing Adsorbtion (PSA)

-

process Material:

-

Zeolite

-

Production Rate:

-

100%

-

Power:

-

5-200KW

-

Product name:

-

oxygen filling station

-

O2 capacity:

-

1~200Nm3/h

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

YG

-

Voltage:

-

220V 380V

-

Weight:

-

15000 KG

-

Dimension(L*W*H):

-

10000*25000*3000mm, According to capacity

-

Certification:

-

CE/ISO9001

-

O2 purity:

-

92%~96%

-

O2 Pressure:

-

150Ba,200Bar

-

Technology:

-

Pressure Swing Adsorbtion (PSA)

-

process Material:

-

Zeolite

-

Production Rate:

-

100%

-

Power:

-

5-200KW

-

Product name:

-

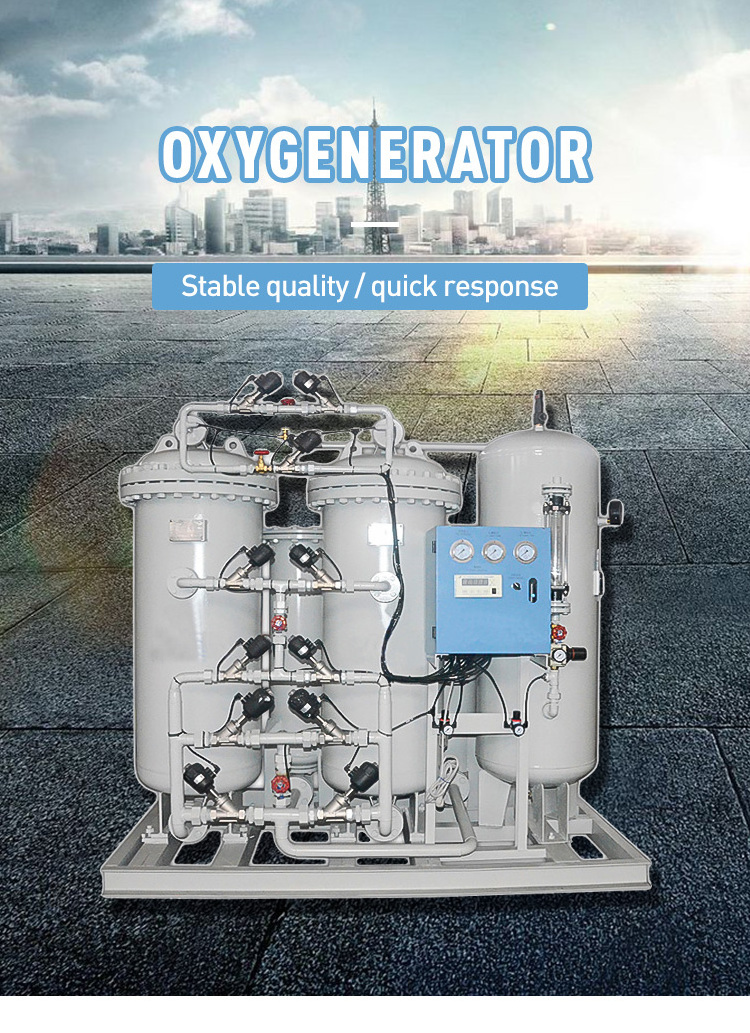

oxygen filling station

-

O2 capacity:

-

1~200Nm3/h

On-site Mobile Gases Systems Psa Vpsa Membrane Liquid Cryogenic Oxygen Nitrogen Generator

Product Description

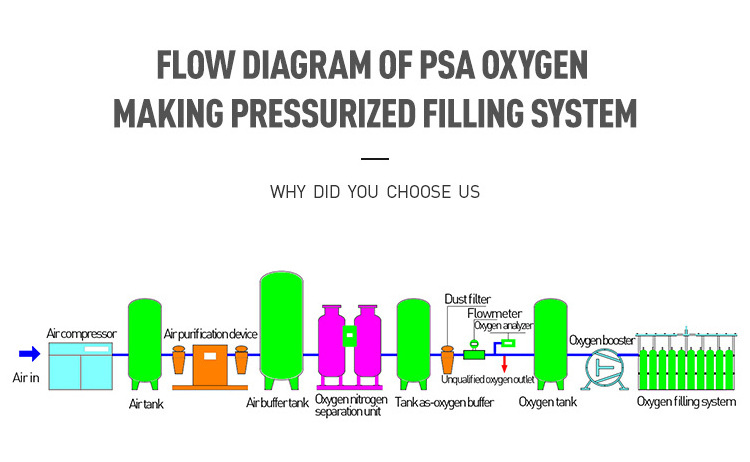

Oxygen generator filling Plant theory

China High Efficiency Medical Oxygen Generator System Medical Oxygen PlantThe pressure swing adsorption oxygen generator uses zeolite molecular sieve as the adsorbent.

China High Efficiency Medical Oxygen Generator System Medical Oxygen PlantThe pressure swing adsorption oxygen generator uses zeolite molecular sieve as the adsorbent.

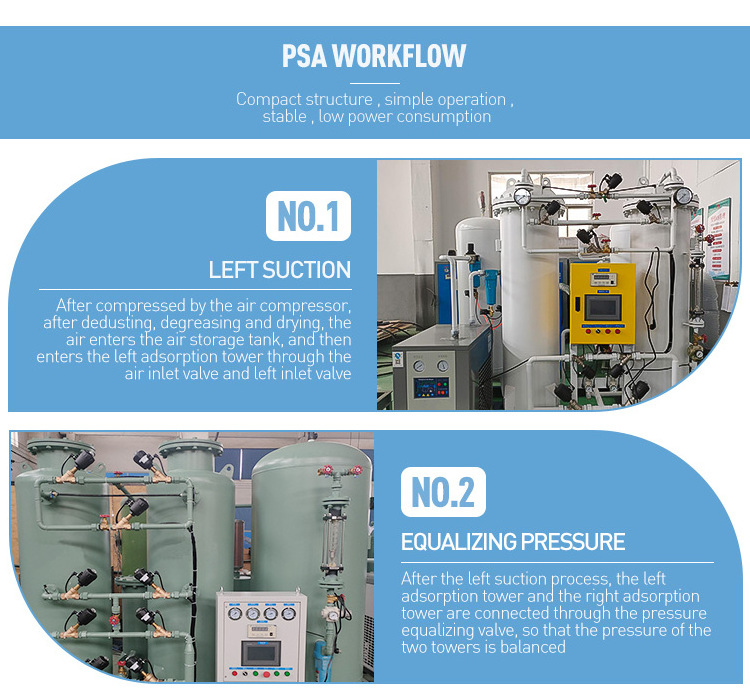

Under a certain pressure, the adsorption capacity of zeolite molecular sieve for nitrogen in the air is much greater than oxygen,therefore, the opening and closing of the pneumatic valve can be controlled through programmable.

The two towers A and B can be cycled alternately, followed by pressure adsorption and decompression desorption to complete the separation of oxygen and nitrogen to obtain oxygen with the required purity.

Specification

|

Oxygen production

|

10-200Nm3/h

|

|

Oxygen purity

|

≥93%±3%

|

|

Inlet pressure

|

≥0.6mpa

|

|

Oxygen outlet pressure

|

0.4MPa (58Psi)

|

|

Dust particle size

|

≤0.01um

Carbon molecular sieve has a service life of more than 5-8 years.

|

|

Weight

|

According to the flow rate and altitude

|

|

Size

|

According to the flow rate and altitude

|

Features

1. The start-up speed is fast, and qualified oxygen can be provided within 15-40 minutes;

2. The equipment is fully automatic, and the whole process can be unattended;

3. Efficient molecular sieve packing, tighter, more solid, and longer service life;

4. The pressure, purity and flow are stable and adjustable to meet the different needs of customers;

5. Reasonable structure, advanced process, safety and stability, low energy consumption;

1. The start-up speed is fast, and qualified oxygen can be provided within 15-40 minutes;

2. The equipment is fully automatic, and the whole process can be unattended;

3. Efficient molecular sieve packing, tighter, more solid, and longer service life;

4. The pressure, purity and flow are stable and adjustable to meet the different needs of customers;

5. Reasonable structure, advanced process, safety and stability, low energy consumption;

Packing & Delivery

1. Packaging

Packed by standard import & export wooden cases or carton boxes.

2. Shipping

By logistics; by automobile; by train; by shipping; by air etc.

Packed by standard import & export wooden cases or carton boxes.

2. Shipping

By logistics; by automobile; by train; by shipping; by air etc.

Hot Searches