- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

U-POLEMAG

-

Model Number:

-

N52

-

Product Name:

-

Neodymium magnet

-

Coating:

-

Epoxy.Black Epoxy. Nickel.Silver.etc

-

Size:

-

Customized Magnet Size

-

Magnetism direction:

-

Thickness. Axial. Radial

-

Usage:

-

Industrial Usage

-

Magnet shape:

-

Round,Disc,Block,Ring,Arc Or special customization

-

Material:

-

Rare Earth Neodymium Magnet

-

Certification:

-

ISO 9001: 2015 ROHS REACH CE

-

Working Temperature:

-

80-220 Degree Centigrade

Quick Details

-

Tolerance:

-

±0.05mm

-

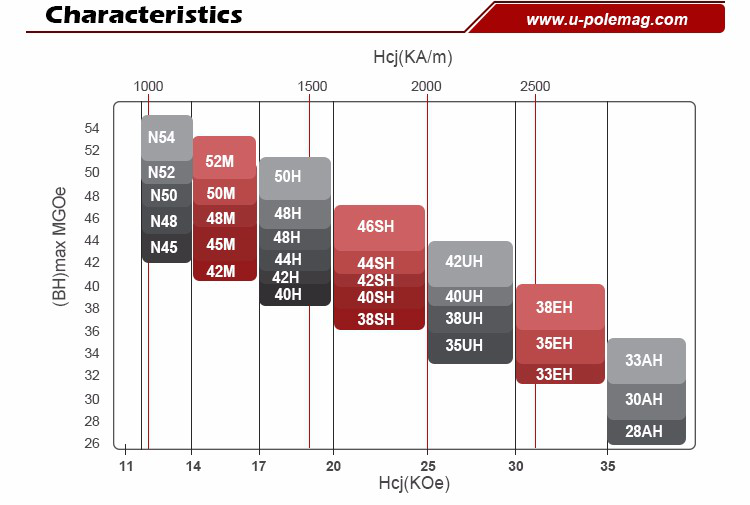

Grade:

-

Neodymium Magnet, N35-N52 (M.H.SH.UH.EH.AH)

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

U-POLEMAG

-

Model Number:

-

N52

-

Product Name:

-

Neodymium magnet

-

Coating:

-

Epoxy.Black Epoxy. Nickel.Silver.etc

-

Size:

-

Customized Magnet Size

-

Magnetism direction:

-

Thickness. Axial. Radial

-

Usage:

-

Industrial Usage

-

Magnet shape:

-

Round,Disc,Block,Ring,Arc Or special customization

-

Material:

-

Rare Earth Neodymium Magnet

-

Certification:

-

ISO 9001: 2015 ROHS REACH CE

-

Working Temperature:

-

80-220 Degree Centigrade

Products Description

Disc N52 Neodymium hijab Magnet

Sintered Neodymium Iron Boron Magnets or "NdFeB" magnets offer the highest energy product of any material today and are available in a wide range of shapes, sizes and grades. NdFeB magnets can be found in a variety of applications including high performance motors, brushless DC motors, magnetic separation, magnetic resonance imaging, sensors and loudspeakers.

Magnetic properties will differ depending upon alignment direction during compaction and upon size and shape.

Table of Magnet Properties

|

Grade

|

Residual magnetism

|

|

Coercive field strength

|

|

|

|

Energy product

|

|

Max.

operational temp. |

|||||

|

|

Br

|

|

bHc

|

|

iHc

|

|

(BxH)max

|

|

|

|||||

|

|

Gauss (G)

|

Tesla (T)

|

kOe

|

kA/m

|

kOe

|

kA/m

|

MGOe

|

kJ/m³

|

°C

|

|||||

|

N30

|

10800-11200

|

1.08-1.12

|

9.8-10.5

|

780-836

|

≥12

|

≥955

|

28-30

|

223-239

|

≤80

|

|||||

|

N33

|

11400-11700

|

1.14-1.17

|

10.3-11

|

820-876

|

≥12

|

≥955

|

31-33

|

247-263

|

≤80

|

|||||

|

N35

|

11700-12100

|

1.17-1.21

|

10.8-11.5

|

860-915

|

≥12

|

≥955

|

33-35

|

263-279

|

≤80

|

|||||

|

N38

|

12200-12600

|

1.22-1.26

|

10.8-11.5

|

860-915

|

≥12

|

≥955

|

36-38

|

287-303

|

≤80

|

|||||

|

N40

|

12600-12900

|

1.26-1.29

|

10.5-12.0

|

860-955

|

≥12

|

≥955

|

38-40

|

303-318

|

≤80

|

|||||

|

N42

|

12900-13200

|

1.29-1.32

|

10.8-12.0

|

860-955

|

≥12

|

≥955

|

40-42

|

318-334

|

≤80

|

|||||

|

N45

|

13200-13700

|

1.32-1.37

|

10.8-12.5

|

860-995

|

≥12

|

≥955

|

43-45

|

342-358

|

≤80

|

|||||

|

N48

|

13700-14200

|

1.37-1.42

|

10.8-12.5

|

860-995

|

≥12

|

≥955

|

45-48

|

358-382

|

≤80

|

|||||

|

N50

|

14000-14600

|

1.40-1.46

|

10.8-12.5

|

860-995

|

≥12

|

≥955

|

47-51

|

374-406

|

≤80

|

|||||

|

N52

|

14200-14700

|

1.42-1.47

|

10.8-12.5

|

860-995

|

≥12

|

≥955

|

48-53

|

380-422

|

≤65

|

|||||

Magnet Plating and Coating Options

The following is a list and description of common plating options for custom magnets.Why do magnets need to be plated?

★ Harsh Environments

Platings vary in their tolerance of different harsh chemicals and abrasion. Salt and humidity in regions near the ocean are

commonly overlooked when selecting a plating. Be sure to consider the magnets environment when selecting a plating.

★

Oxidization (Rust)

NdFeB magnets will oxidize(rust) if left exposed. When a plating wears down or cracks, the exposed area will oxidize. An oxidized area will not result in complete degradation of the magnet, only the oxidized area will lose its strength. However the magnet will lose some structural integrity and become more susceptible to breakage.

NdFeB magnets will oxidize(rust) if left exposed. When a plating wears down or cracks, the exposed area will oxidize. An oxidized area will not result in complete degradation of the magnet, only the oxidized area will lose its strength. However the magnet will lose some structural integrity and become more susceptible to breakage.

★

Durability

Depending on shape, permanent magnet substrate is brittle. A multilayered metal plating like nickel or zinc improves the magnets resistance to chipping and wear, particularly around corners.

Depending on shape, permanent magnet substrate is brittle. A multilayered metal plating like nickel or zinc improves the magnets resistance to chipping and wear, particularly around corners.

★ Harsh Environments

Platings vary in their tolerance of different harsh chemicals and abrasion. Salt and humidity in regions near the ocean are

commonly overlooked when selecting a plating. Be sure to consider the magnets environment when selecting a plating.

The most common type of plating for neodymium magnets Nickel (Ni-Cu-Ni) Intended for indoor use. It has proven to be very resilient when subjected to normal wear and tear. However it will corrode oudoors in prolonged exposure to salt water, salty air,or harsh chemicals.

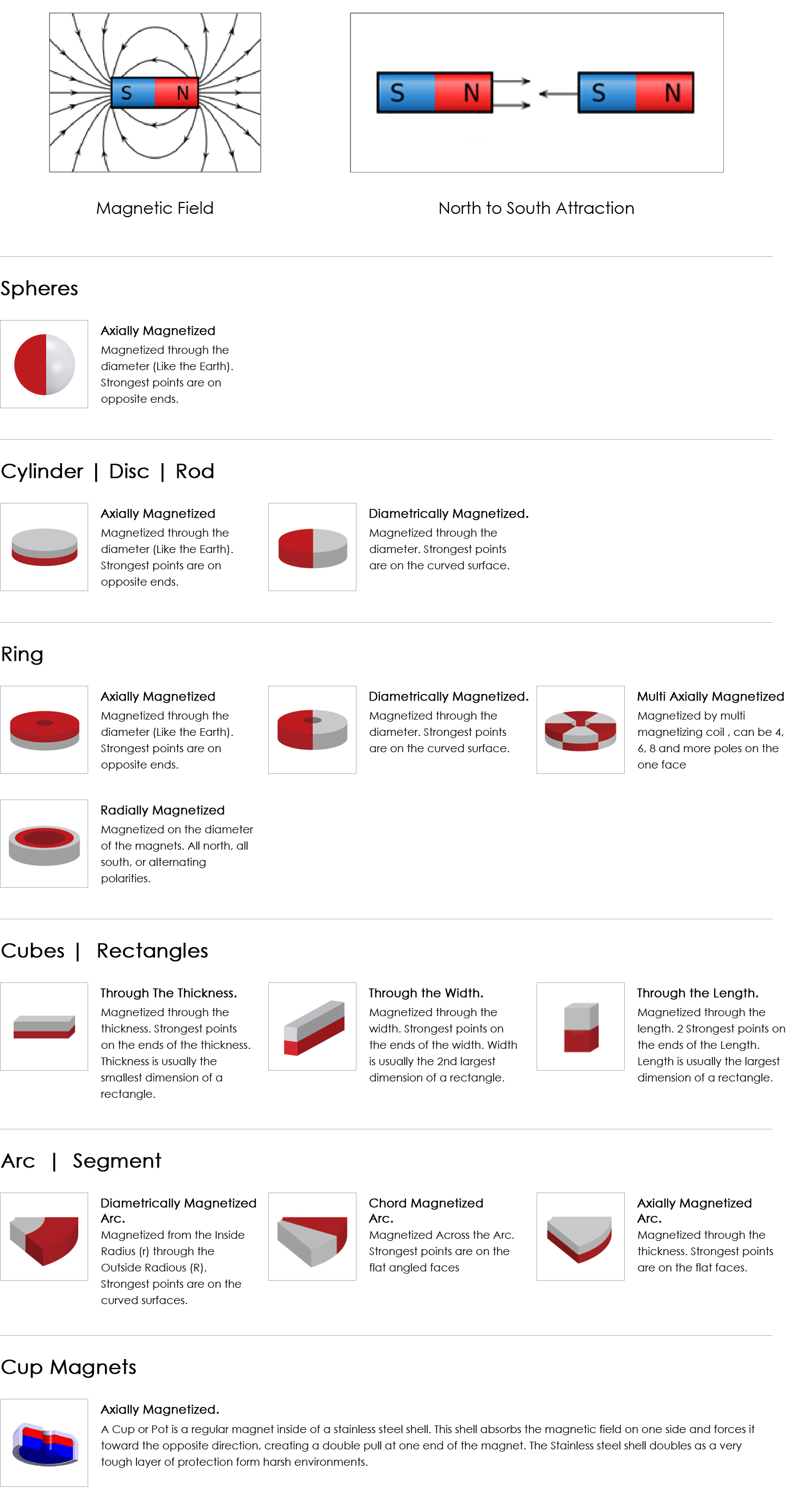

Magnetization Direction

A Magnetic field is an invisible flux moving from one end of the magnet to the other. Shown in Figure1. The flux consists of

moving or spinning electrically charged particles invisible to the eye. If the max working temperature meet the requirement ,permanent magnets can retain the magnetic field for very long time even forever. Magnets have potential energy which means that they have the ability to conserve energy. The magnet will display or release some of its conserved energy when pulling towards or attaching to something then conserve or store the energy that the user exerts when pulling it off.

moving or spinning electrically charged particles invisible to the eye. If the max working temperature meet the requirement ,permanent magnets can retain the magnetic field for very long time even forever. Magnets have potential energy which means that they have the ability to conserve energy. The magnet will display or release some of its conserved energy when pulling towards or attaching to something then conserve or store the energy that the user exerts when pulling it off.

Every magnet has a north seeking and a south seeking face on opposite ends. The north face of one magnet will always be attracted towards the south face of another magnet.

Application Fields

Neodymium magnets are strong magnets,frequently used for many types of sectors, commercial, industrial & technical applications where strong permanent magnets are required. Due to their high-magnetic strength, components that previously had to be large and heavy can now be miniaturized by using Neodymium magnet material.Common Applications: holding systems requiring very high holding forces, sensors, reed switches, hard disc drives, audio equipment, acoustic pick-ups, headphones & loudspeakers, MRI scanners, magnetically coupled pumps · motors & generators, magnetic tool holders, magnetic bearings, door catches, dental instruments, medical devices, magnetic separators, lifting machinery, crafts & model making, hanging artwork, levitation devices, POP displays, commercial signage, packaging closures, jewelry clasps & more.

U-Polemag can make large inventory of Neodymium magnets in disc, block, rod , ring , arc & customized irregular shapes, in a wide range of shapes, sizes and grades. Just let us know what you are looking for by sending us a request for quote or contact us to discuss your specialty project.

U-Polemag can make large inventory of Neodymium magnets in disc, block, rod , ring , arc & customized irregular shapes, in a wide range of shapes, sizes and grades. Just let us know what you are looking for by sending us a request for quote or contact us to discuss your specialty project.

Why Choose Us

Advanced Facilities

Excellent production equipment

Product Testing

Strict product testing process

Engineering Service

Meet all customer needs

About U-POLEMAG

U-Polemag Industry Ltd founded in 2004, is a high technology company engaged in reaching, developing, manufacturing and marketing magnets and their application devices with ISO9001,ISO14001,ISO18001 and ISO/TS16949 certificates.

As a supplier of magnetic material and devices, by taking markets as the orientation and customers’ demands as criterion,

U-polemag continuously improves technologies and products, and insists in providing customers with first-class goods and services.

U-polemag continuously improves technologies and products, and insists in providing customers with first-class goods and services.

With years of development and accumulation, we can supply high quality neodymium magnets ,samarium cobalt magnets, ceramic magnets and various of customized magnetic application products such as magnetic holders

magnetic coupling, motor parts, speaker divers and so on

FAQ

Q: May we get a sample of the product? How to ship and how to pay ?

A:

Yes,the samples testing should be necessary for first time , we would like cooperate for samples.

If it's regular magnets and we have stock , we would like supply free samples for customers, if need new production , we will quote samples fee

and we can accept T/T, Paypal , Western Union , Alibaba trade assurance for payment.

We will send the sample to you by

DHL

express.

Q: What magnet materials are available?

A:

There are many different magnet materials available, which we are able to provide. These include neodymium, samarium cobalt,alnico, ferrite, bonded neodymium, bonded samarium cobalt, bonded ferrite, injection molded neodymium, injection molded samarium cobalt, rubber stripping, and FeCrCu. If there is another material you wish to procure, please contact us.

Q:Can you supply custom magnets?

A:

Yes, we have the capability to produce magnets to your specification in NdFeB, SmCo, AlNiCo, Ferrite, and rubberized magnet materials. You can contact us for more details .

Q:Do you have a minimum purchase order?

A:

The manufacturing of magnets is a complex process, please check our production flow for more information. As considering the production time and cost, we suggest the batch order value should be more than US$3000 per time; Of course, if less than US$3000,we also would like quote our offer for your kind consideration, so we have no strict MOQ .

Q: How many days does it take to ship my order?

A: In generally, the sintering NdFeB and SmCo magnet production time is 15-25days, cast AlNiCo will take 25-30days , the magnetic assemblies will be about 30-40 days for your reference , the exact time need to be checked before the order .

Q:What elements affect the magnet price ?

A: 1. Shape and size : cylinder (DxH), cuboids(LxWxH) ,cubes, ring(ODxIDxH) belong to regular shape , arc magnets are popular used in motors or generators , before quotation and batch production , we have to confirm the technical drawing and samples, other irregular shape magnets are also can be made according to request.

2: Grade (Magnetic Property)

3: Plating(Coating)

4:Magnetizing Orientation

5:Quantity

2: Grade (Magnetic Property)

3: Plating(Coating)

4:Magnetizing Orientation

5:Quantity

Hot Searches