- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

JHENTEN

-

Dimension(L*W*H):

-

/

-

Capacity:

-

100-10000L

-

Weight:

-

200

-

Inner Material:

-

304/316L/C22/C275/904L

-

Outer Material:

-

304/316L

-

Design Pressure(MPa):

-

-1-10MPa

-

Design Standard:

-

ASME.PED.GB.

-

Working Temperature(℃):

-

-20 - 200 ℃

-

Applicable Industries:

-

Daily chemical industry, beverage industry, Chemicals Processing, Plastics Processing, Food Processing

-

Surface roughness:

-

0.3um-0.6um

-

Material:

-

SS304/SS316

-

Application:

-

chemical,metallurgy,food,chemical fiber

-

Certification:

-

ASME

Quick Details

-

Volume (m³):

-

customizable,According to capacity

-

Max Working Pressure(MPa):

-

1.5Mpa

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

JHENTEN

-

Dimension(L*W*H):

-

/

-

Capacity:

-

100-10000L

-

Weight:

-

200

-

Inner Material:

-

304/316L/C22/C275/904L

-

Outer Material:

-

304/316L

-

Design Pressure(MPa):

-

-1-10MPa

-

Design Standard:

-

ASME.PED.GB.

-

Working Temperature(℃):

-

-20 - 200 ℃

-

Applicable Industries:

-

Daily chemical industry, beverage industry, Chemicals Processing, Plastics Processing, Food Processing

-

Surface roughness:

-

0.3um-0.6um

-

Material:

-

SS304/SS316

-

Application:

-

chemical,metallurgy,food,chemical fiber

-

Certification:

-

ASME

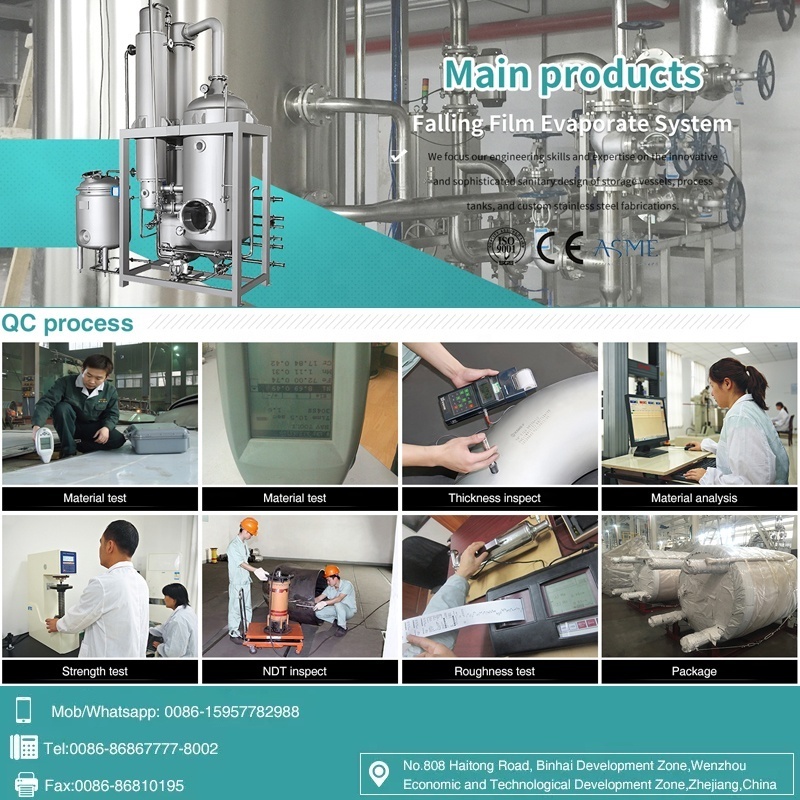

Products Description

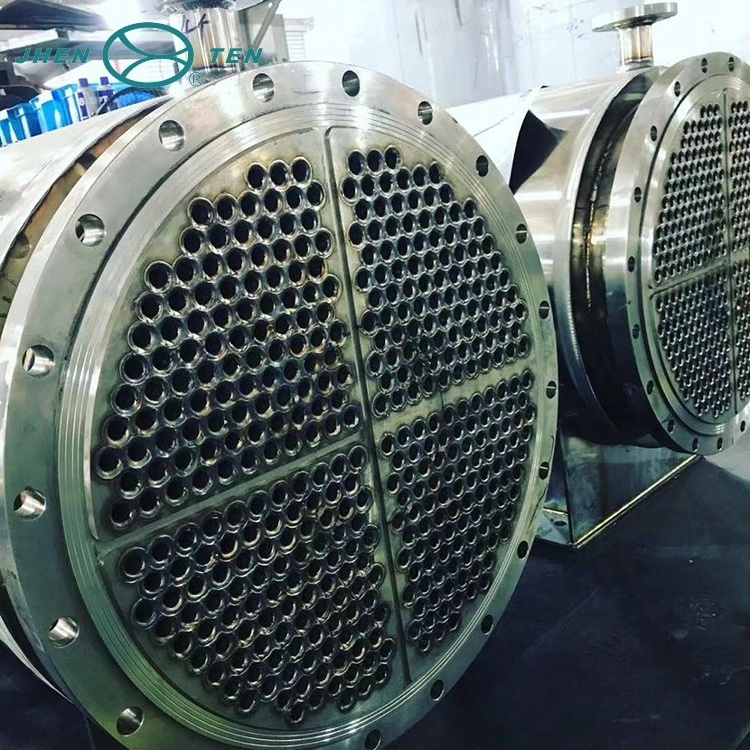

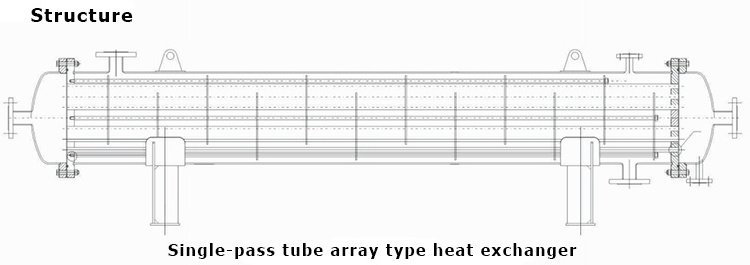

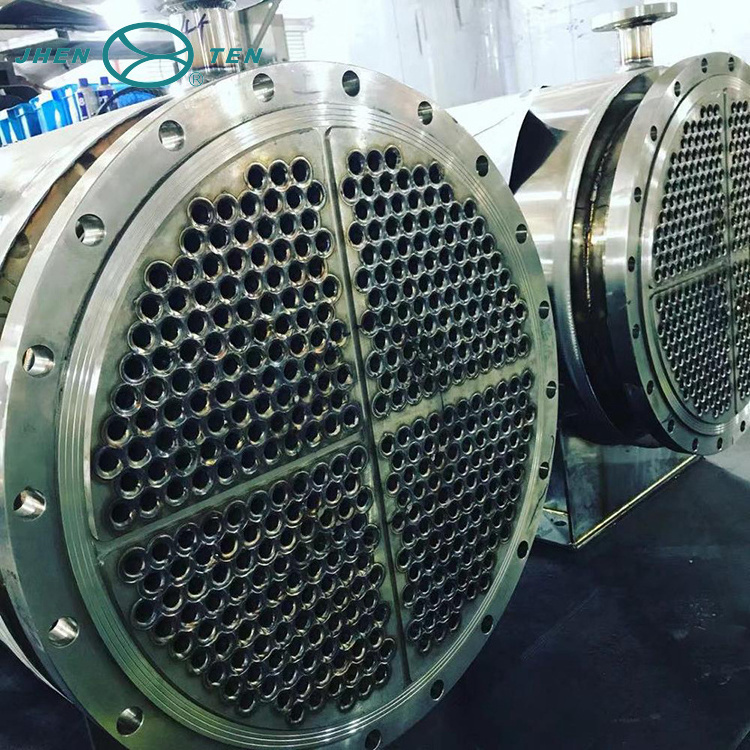

Feature of Single-pass tube array type heat exchanger

• Custom-made design, the latest technology of water pressure pipeline expansion-no hardening in contact surface, scratches, thin walls and scars.

• Custom-made design for the latest scientific and technological track welding of pipeline to pipe sheet welding seal.

• The pipe bending equipment designed by all U tube can ensure that the pipe has a good contact surface in the U curved area.

• The surface roughness of all heat exchangers is 0.6um to 0.3um including the electronic grade seamless tube.

• The roughness of the sanitary welded pipe can be higher than 0.75um.

• The design of the U-type tube and the straight tube 100% meets the requirements of the ASME BPE 2005.

• Strict QA/QC procedures.

• The excellent document control department produces all the certification documents. Over the past 50 years.

Application of heat exchanger

Tube heat transfer tubes are widely used in chemical, light industry.metallurgy, pharmaceutical, food, chemical fiber and so on.

|

Operation

|

|

|

|

Shell Design Pressure

|

0.6MPa 1.0MPa

|

|

|

Shell Design Temperature

|

150ºC

|

|

|

Tube Desian Pressure

|

0.6MPa 1.0MPa

|

|

|

Tube Desian Temperature

|

150ºC

|

|

|

Tube No.

|

2001/2/4

|

|

|

Material

|

|

|

|

Shell

|

304, 316L

|

|

|

Tube

|

304, 316L

|

|

|

O-ring

|

EPDM, PTFE, silicon

|

|

|

Connection

|

|

|

|

Tube connection

|

Clamp, Flange, Screw

|

|

|

Shell connection

|

Clamp, Flange

|

|

|

Surface Finish

|

|

|

|

Finish type

|

Mechanical / electrolytic polishing

|

|

|

Polishing precision

|

0.4um

|

|

|

Diameter

|

Tube No.

|

Pipe No.

|

Trans surface Pipe lenght(mm)

|

|

|

|

|

||||

|

|

|

|

1500

|

2000

|

3000

|

4000

|

6000

|

||||

|

159

|

L

|

14

|

1.5

|

2

|

3

|

4.5

|

6.6

|

||||

|

219

|

I

|

26

|

3

|

4

|

6

|

8

|

12

|

||||

|

|

II

|

26

|

3

|

4

|

6

|

8

|

12

|

||||

|

273

|

I

|

44

|

5

|

7

|

10

|

14

|

21

|

||||

|

|

II

|

40

|

5

|

6

|

9

|

12

|

19

|

||||

|

325

|

I

|

60

|

7

|

9

|

14

|

19

|

28

|

||||

|

|

II

|

56

|

6

|

9

|

13

|

17

|

26

|

||||

|

400

|

I

|

119

|

14

|

18

|

28

|

37

|

55

|

||||

|

|

II

|

110

|

13

|

17

|

26

|

34

|

50

|

||||

|

500

|

I

|

185

|

22

|

29

|

45

|

55

|

85

|

||||

|

|

II

|

170

|

20

|

27

|

40

|

55

|

85

|

||||

|

600

|

I

|

277

|

33

|

43

|

60

|

85

|

125

|

||||

|

|

II

|

266

|

31

|

41

|

60

|

80

|

125

|

||||

|

700

|

I

|

379

|

44

|

59

|

90

|

120

|

125

|

||||

|

|

II

|

358

|

42

|

56

|

85

|

110

|

165

|

||||

|

800

|

I

|

511

|

60

|

80

|

120

|

160

|

240

|

||||

|

|

II

|

488

|

57

|

77

|

115

|

150

|

230

|

||||

|

900

|

I

|

649

|

76

|

102

|

150

|

200

|

305

|

||||

|

|

II

|

630

|

73

|

99

|

145

|

195

|

295

|

||||

|

1000

|

I

|

805

|

95

|

126

|

185

|

250

|

375

|

||||

|

|

II

|

792

|

92

|

124

|

185

|

245

|

370

|

||||

Hot Searches