- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

750kg

-

Size:

-

331*100*170cm

-

Power:

-

1.3kw

-

Weight (KG):

-

200 kg

-

Designed For:

-

Wastewater Reuse, Sewage Recycling

-

Treatment Capacity:

-

72-240 Ton/day

-

MBR Membrane Type:

-

Flat Sheet Membrane

-

MBR Membrane Material:

-

Reinforced PVC/PVDF

-

Certificate:

-

ISO9001

-

Power Source:

-

380V, customizable

-

Lead Time:

-

35-40 Working Days

-

Main Application:

-

Reclaimed Water Reuse

-

Product Type:

-

MBR shower water recycling system

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

JWT

-

Material:

-

plywood

-

Weight:

-

750kg

-

Size:

-

331*100*170cm

-

Power:

-

1.3kw

-

Weight (KG):

-

200 kg

-

Designed For:

-

Wastewater Reuse, Sewage Recycling

-

Treatment Capacity:

-

72-240 Ton/day

-

MBR Membrane Type:

-

Flat Sheet Membrane

-

MBR Membrane Material:

-

Reinforced PVC/PVDF

-

Certificate:

-

ISO9001

-

Power Source:

-

380V, customizable

-

Lead Time:

-

35-40 Working Days

-

Main Application:

-

Reclaimed Water Reuse

-

Product Type:

-

MBR shower water recycling system

Product Description

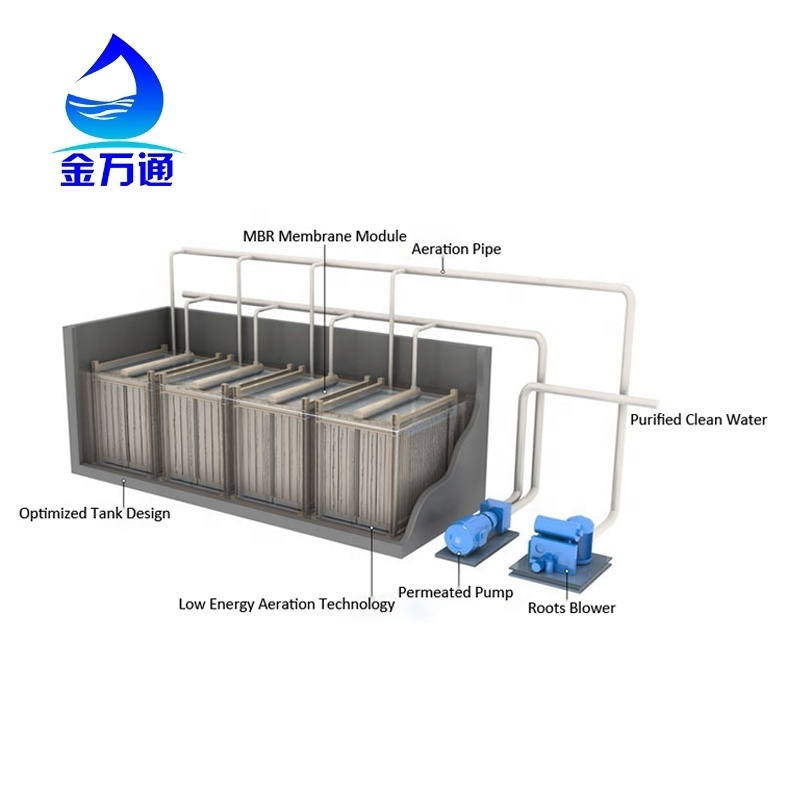

MBR shower water recycling system is an integrated new wastewater treatment system which combines membrane separation technology

and bio-technology, purified clean effluent quality is super high, can be recycled and reused directly.

Hydraulic retention time (HRT) and sludge retention time (SRT) can be separately controlled, the refractory organics are trapped

by membrane separation device and are continously decomposed, activated sludge concentration is greatly improved.

MBR shower water recycling system is now widely used for municipal and industrial wastewater recycling and reuse.

As an experienced manufacturer started in year 2006, we provide one-stop services from project design to manufacturing,

installation and final commissioning, professional services with cheap factory price for you.

Product Features

Features of MBR shower water recycling system:

1. Super high purified clean water quality:

Purified water is perfectly separated from suspended solids, colloidal substances and microbial flora, high efficiency

solid-liquid separation technology ensure excellent water quality, purified clean water can be reused directly, don't need

tertiary treatment.

2. Save space and investment:

Activated sludge concentration remains high, volumetric loading rate is greatly improved. At the same time because of the

efficient membrane separation performance, hydraulic retention time(HRT) is greatly shortened, thus reduces MBR membrane

bioreactor land occupation, only need 1/3 land compared to traditional equipment.

Also MBR shower water recycling system don't need secondary sedimentation tank, greatly saved space and investment.

3. Save operation costs, extend reclaimed water application scope:

MBR shower water recycling system can filter out bacteria, viruses and other harmful substances, thus greatly saving long-term

operating costs caused by chemical dosing and disinfection, also extend purified clean water reuse application scope.

4.

Stable running performance and flexible control:

Efficient membrane separation perfectly trap macromolecular organics and hold them inside system, thus achieving completely

separation of hydraulic retention time (HRT) and sludge retention time (SRT). System running is more stable, control is more

flexible.

5. Strong shock resistance, wide adaptation and application scope:

MBR membrane avoid loss of various microbial flora, it is much helpful for slow growing bacteria (e.g. nitrifying bacteria).

Residence time is prolonged, much helpful for decomposition and degradation of refractory macromolecular organics. Whole

system metabolism run smoothly, with strong shock resistance and wide adaptation & application scope.

6. Little sludge discharge, low sludge disposal costs.

Almost no excess sludge generated during system operation, low sludge disposal costs.

7. Three type of products for you:

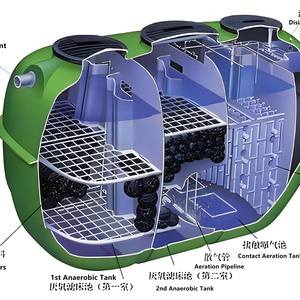

7.1 Buried Underground Type

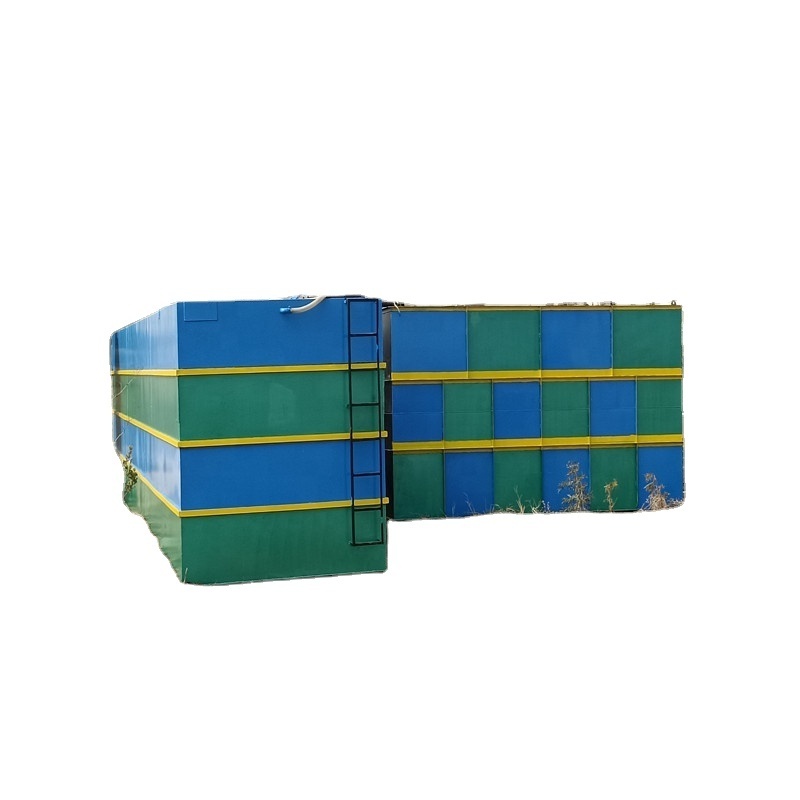

7.2 On Ground Type

7.3 Mobile Type for Mobile Application

Applications of MBR membrane bioreactor wastewater reuse system:

1. For civil buildings:

Sewage treatment and reclaimed water reuse for office buildings, residential areas, hospitals, hotels, schools, stadiums, etc..

2. For areas where without drainage network system:

Sewage treatment for tourism scenic spots, resorts, villas, railway stations, toll stations, airport, temporary construction

sites, mobile oilfield labor camp, etc..

3. For industrial wastewater treatment:

Suit for high concentration organic wastewater treatment for mining industry, pharmaceutical industry, food industry, sugar

industry, alcohol industry, leather industry, paper industry, printing and dyeing industry, etc..

MBR membrane bioreactor wastewater reuse system is now widely used for municipal and industrial wastewater recycling and reuse.

Strong technical team and strict inspections ensure excellent quality and service life of MBR membrane bioreactor wastewater reuse

system.

Detail images of MBR membrane bioreactor wastew:

Type I--Underground Type: Type II--Above Ground Type

Features of MBR shower water recycling system:

1. Super high purified clean water quality:

Purified water is perfectly separated from suspended solids, colloidal substances and microbial flora, high efficiency

solid-liquid separation technology ensure excellent water quality, purified clean water can be reused directly, don't need

tertiary treatment.

2. Save space and investment:

Activated sludge concentration remains high, volumetric loading rate is greatly improved. At the same time because of the

efficient membrane separation performance, hydraulic retention time(HRT) is greatly shortened, thus reduces MBR membrane

bioreactor land occupation, only need 1/3 land compared to traditional equipment.

Also MBR shower water recycling system don't need secondary sedimentation tank, greatly saved space and investment.

3. Save operation costs, extend reclaimed water application scope:

MBR shower water recycling system can filter out bacteria, viruses and other harmful substances, thus greatly saving long-term

operating costs caused by chemical dosing and disinfection, also extend purified clean water reuse application scope.

4.

Stable running performance and flexible control:

Efficient membrane separation perfectly trap macromolecular organics and hold them inside system, thus achieving completely

separation of hydraulic retention time (HRT) and sludge retention time (SRT). System running is more stable, control is more

flexible.

5. Strong shock resistance, wide adaptation and application scope:

MBR membrane avoid loss of various microbial flora, it is much helpful for slow growing bacteria (e.g. nitrifying bacteria).

Residence time is prolonged, much helpful for decomposition and degradation of refractory macromolecular organics. Whole

system metabolism run smoothly, with strong shock resistance and wide adaptation & application scope.

6. Little sludge discharge, low sludge disposal costs.

Almost no excess sludge generated during system operation, low sludge disposal costs.

7. Three type of products for you:

7.1 Buried Underground Type

7.2 On Ground Type

7.3 Mobile Type for Mobile Application

Applications of MBR membrane bioreactor wastewater reuse system:

1. For civil buildings:

Sewage treatment and reclaimed water reuse for office buildings, residential areas, hospitals, hotels, schools, stadiums, etc..

2. For areas where without drainage network system:

Sewage treatment for tourism scenic spots, resorts, villas, railway stations, toll stations, airport, temporary construction

sites, mobile oilfield labor camp, etc..

3. For industrial wastewater treatment:

Suit for high concentration organic wastewater treatment for mining industry, pharmaceutical industry, food industry, sugar

industry, alcohol industry, leather industry, paper industry, printing and dyeing industry, etc..

MBR membrane bioreactor wastewater reuse system is now widely used for municipal and industrial wastewater recycling and reuse.

Strong technical team and strict inspections ensure excellent quality and service life of MBR membrane bioreactor wastewater reuse

system.

Detail images of MBR membrane bioreactor wastew:

Type I--Underground Type: Type II--Above Ground Type

|

Model

|

Treatment Capacity(m3/d)

|

Overall Size(m)

|

Frame Material

|

Land Occupation(m2)

|

|

MBR-80

|

72

|

2.6×1.8×2.5

|

As per required

|

4.7

|

|

MBR-120

|

120

|

3.8×1.8×2.5

|

As per required

|

6.8

|

|

MBR-240

|

240

|

3.8×3.6×2.5

|

As per required

|

13.7

|

Type

III--Mobile Type for Mobile Application-- Inside a Standard Shipping Container:

For more details, please feel free to contact us:

Experienced manufacturer started in year 2006, one-stop services from design to installation with cheap factory price for you.

Detail Specification

Deatai specification of MBR shower water recycling system:

Customized service are accepatable:

Standard treatment capacity is 72-240m3/day, if you need higher treatment capacity, please feel free to contact us, professional

design for you !

Welcome to my shop:

https://www.alibaba.com/product-detail/Integrated-Sewage-Treatment-Sewage-Water-Treatment_1600914748201.html?spm=a2747.manage.0.0.605c71d2aycWfd

Qingdao Jinwantong Environmental Science And Technology Co., Ltd.

Custom manufacturer

CN 10YRS

Supplies Fortune 500 companies

Store rating

4.7/5

On-time delivery rate

100.0%

Response time

≤3h

Total annual revenue

$600000

Floorspace

8000m²

Patents awarded

3

Services

Design-based customization

Full customization

Quality control

Raw-material traceability identification

Finished product inspection

Certifications

WhatsApp/weChat+8618669718510

Email:stephanie@eyeview.vip

Hot Searches