- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

200(control)/380(weld)

-

Current:

-

depends on welding

-

Rated Capacity:

-

depends on welding machine

-

Rated Duty Cycle:

-

100%

-

Dimensions:

-

2300*900*1500mm

-

Use:

-

Control welding process

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

welding machine:

-

OEM

-

giant tig weld machine:

-

OEM

-

Parameters:

-

Refer to details

-

welding power:

-

380V

-

control power:

-

220V

-

color:

-

blue

-

Weight:

-

700kg

-

Certification:

-

CE/ISO9001

Quick Details

-

Place of Origin:

-

Sichuan, China

-

Brand Name:

-

Hanyan Technology

-

Weight (KG):

-

430

-

Voltage:

-

200(control)/380(weld)

-

Current:

-

depends on welding

-

Rated Capacity:

-

depends on welding machine

-

Rated Duty Cycle:

-

100%

-

Dimensions:

-

2300*900*1500mm

-

Use:

-

Control welding process

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

welding machine:

-

OEM

-

giant tig weld machine:

-

OEM

-

Parameters:

-

Refer to details

-

welding power:

-

380V

-

control power:

-

220V

-

color:

-

blue

-

Weight:

-

700kg

-

Certification:

-

CE/ISO9001

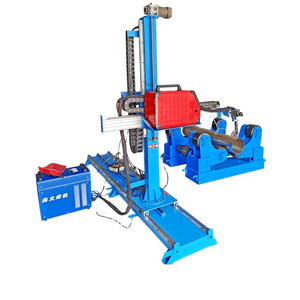

1.Introduction

1.1. Application:

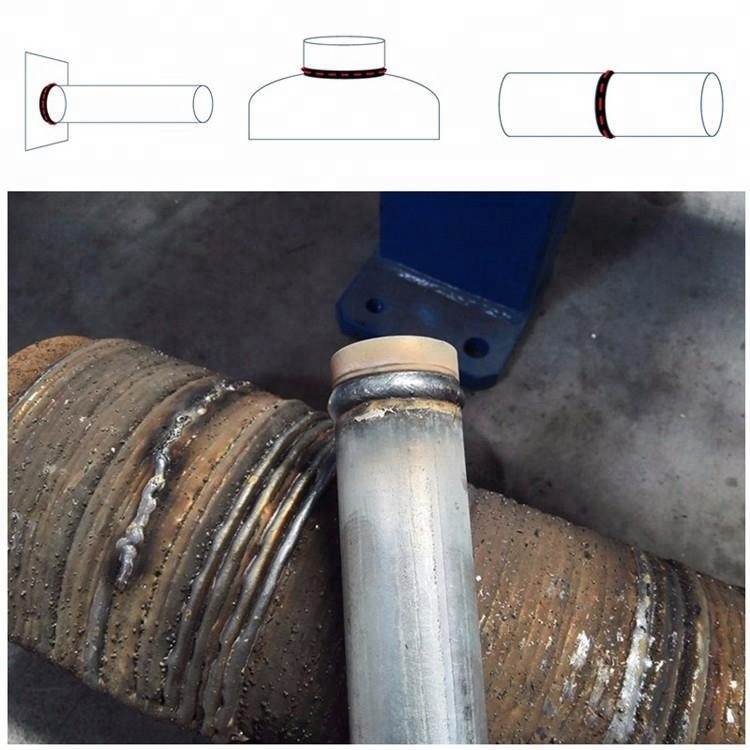

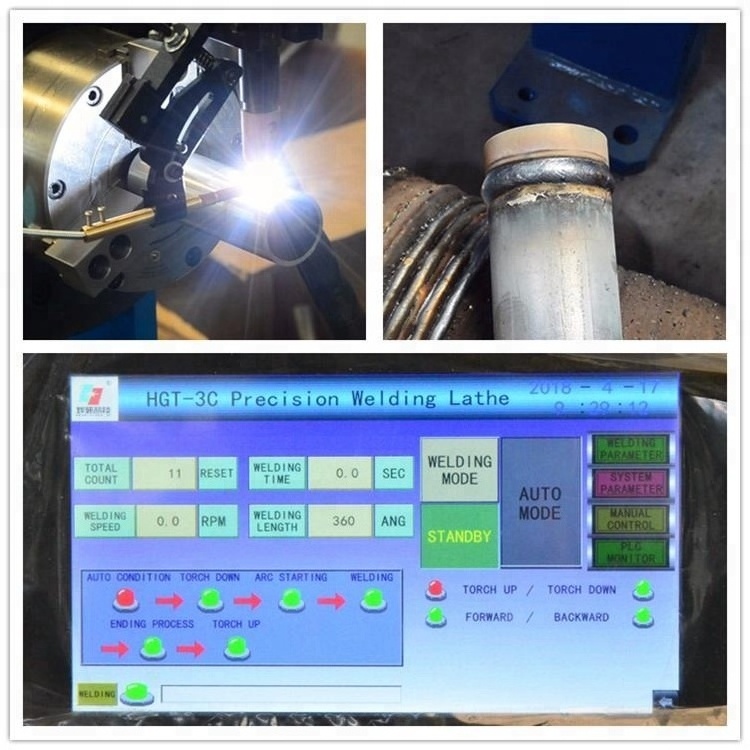

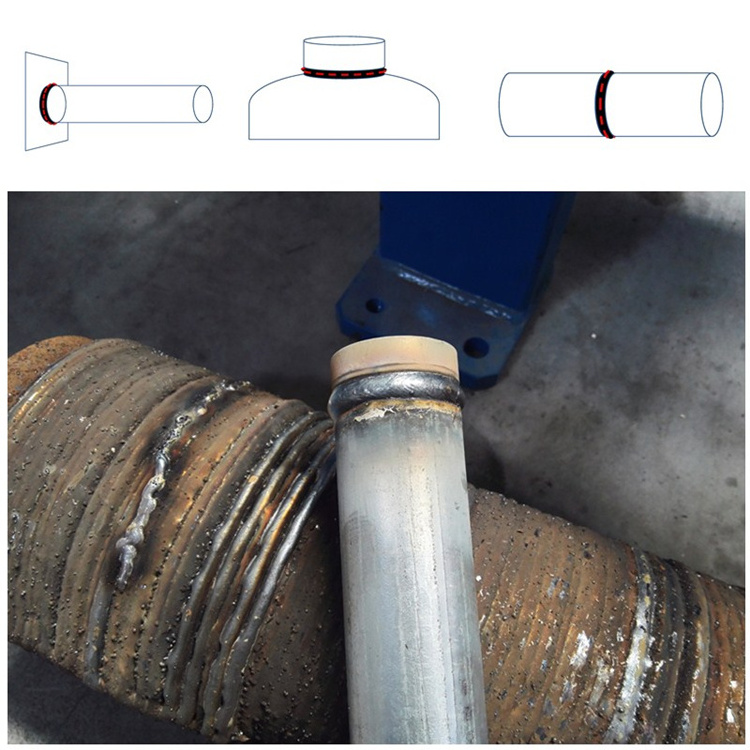

It can constitute an circumferential seam automatic welding system with proper welding sources and welding gun, to achieve automatic welding, and improve welding speed and quality. It’s mainly used in instrument, bellows, medical device and electronic components and other precision workpeice.

1.2. Components:

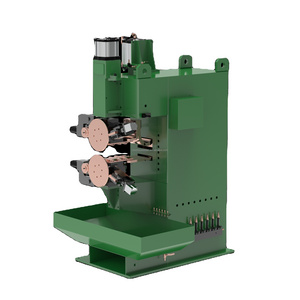

It main consist of rotation headstock, tailstock, lathe bed, 3-D adjusting mechanism, pneumatic lifter, travel mechanism and PLC controlling system. Combined structure is convenient for installation, and has a good mobility.

1.2.1. Lathe Bed: With guide rail, and the distance between headstock and tailstock is adjustable.

1.2.2. Rotation Headstock: Driven by DC gear motor, has stepless speed regulation function and welding current detection switch.

1.2.3. Tailstock: Operate hand whell, and impart motion to center.

1.2.4. Adjustable 3-D Device: Adjust torch position accurately.

1.2.5. Pneumatic Lifter: Lift up torch automatically.

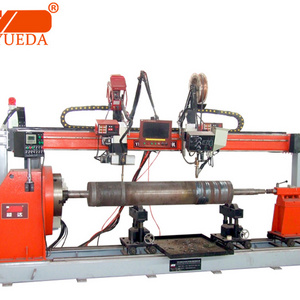

1.2.6. Travel Mechanism: Automatic longitudinal seam welding and carriage movement achieved.

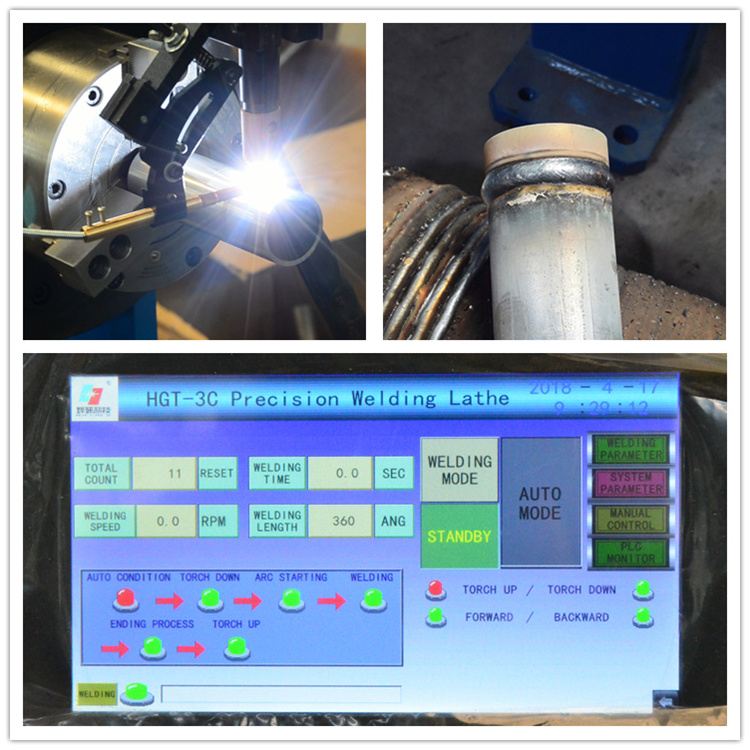

1.2.7. Control System: Advanced PLC controlling system, humanized operation interface, high degree automation, stable and reliable performance.

1.3. Welding Process:

1.3.1. Welding Mode: torch fixed, workpiece rotating, welding porcess control, automate welding procedue.

1.3.2. Welding Method: It can be used with argon arc welding machine (supporting the use of wire feeder), CO2/MAG/MIG welding machine, pulsing welding machine or other welding sources to form an automatic girth (longitudinal) seam welding system.

Technical Parameters

In user factory:

1. Before sales: on site techinical solution and quotation.

2. after sales: installation, commisionning, training.

In our factory: