- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

HSDZJ

-

Voltage:

-

380V

-

Power:

-

customization

-

Dimension(L*W*H):

-

customization

-

Weight (KG):

-

4000

-

Machine name:

-

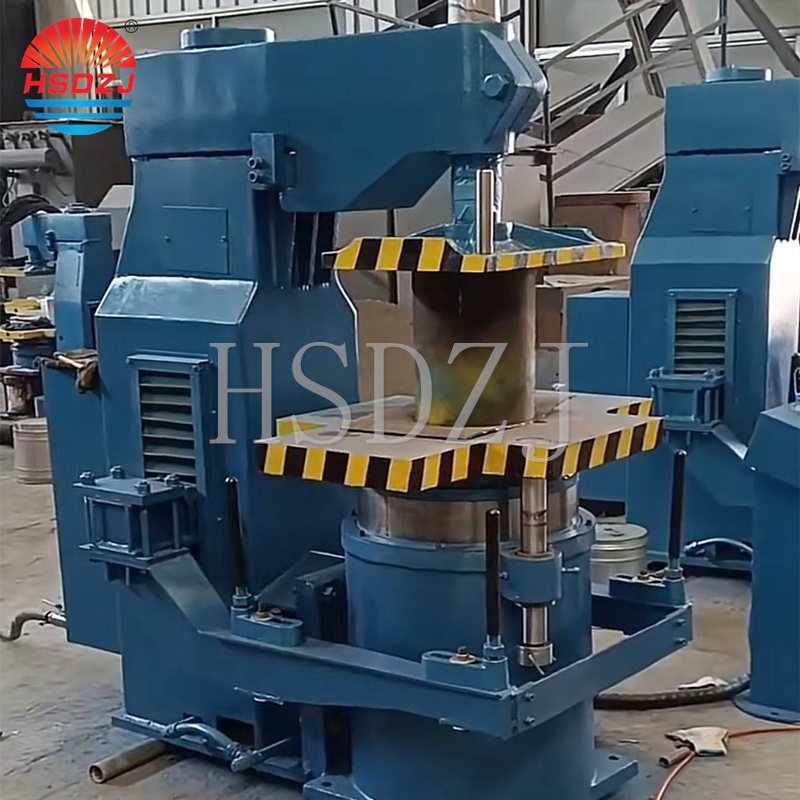

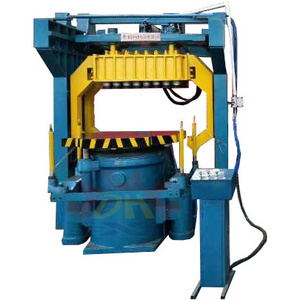

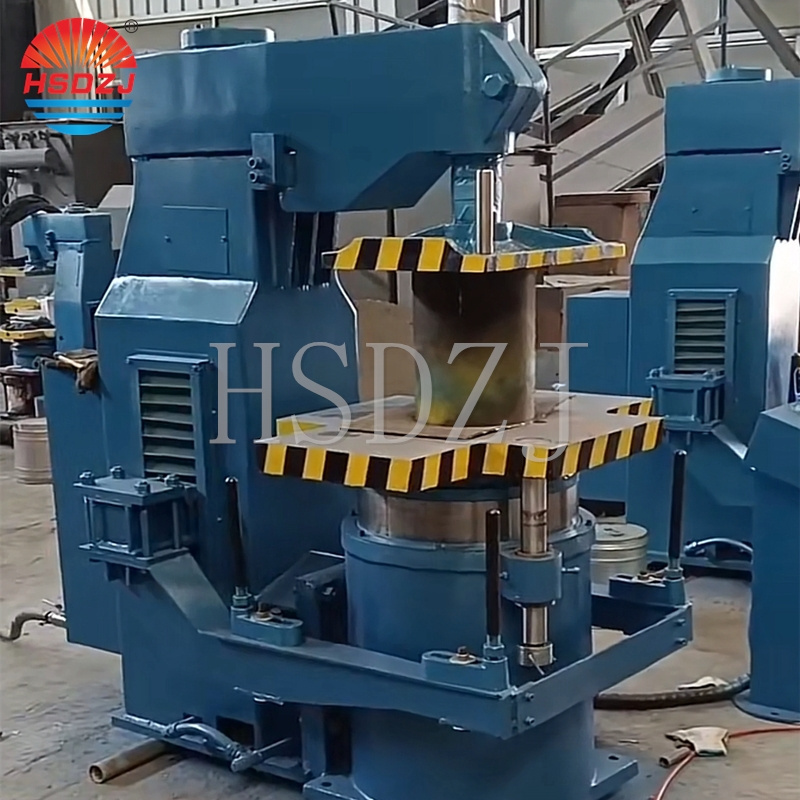

Green sand molding machine

-

Product series:

-

Z14 series

-

Modeling methods:

-

Hand molding

-

Sand box size:

-

According to machine model

-

Productivity:

-

60-80 box/hour

-

Air pressure:

-

0.6Mpa

-

Shock force:

-

According to machine model

-

Crushing force:

-

According to machine model

-

Boundary dimension:

-

According to machine model

-

Machine weight:

-

According to machine model

Quick Details

-

Place of Origin:

-

Shandong, China

-

Machine Type:

-

Casting molding

-

Warranty of core components:

-

2 Year

-

Brand Name:

-

HSDZJ

-

Voltage:

-

380V

-

Power:

-

customization

-

Dimension(L*W*H):

-

customization

-

Weight (KG):

-

4000

-

Machine name:

-

Green sand molding machine

-

Product series:

-

Z14 series

-

Modeling methods:

-

Hand molding

-

Sand box size:

-

According to machine model

-

Productivity:

-

60-80 box/hour

-

Air pressure:

-

0.6Mpa

-

Shock force:

-

According to machine model

-

Crushing force:

-

According to machine model

-

Boundary dimension:

-

According to machine model

-

Machine weight:

-

According to machine model

I. Introduction of the machine

Z14 series micro-vibration compaction molding machine is the most common molding equipment for green sand casting. The whole machine is composed of fuselage, jolt mechanism, sand adding mechanism, indenter, mold drawing mechanism and control system. The size of the sand mold can be selected from 300-1200mm, which can meet the use of common castings. Suitable for medium and small manual and semi-mechanized casting workshops.

Working process: When modeling, first pull away the upper pressure plate, put the sand box on the template frame of the workbench (sometimes need to put the auxiliary frame). Then fill in the molding sand. When the sand is filled, the jar cylinder can also be activated to produce a jolt, so that the molding sand edge is filled in, and the edge is initially compacted. At this time, the pressure plate is turned back to the central position relative to the sand box, and then the compacted cylinder is started, so that the workbench and the sand box rise together, the pressure plate is pressed into the auxiliary frame, and the molding sand is compacted. When the table rises, the four ejector rods rise together, when the table falls, the four ejector rods cannot fall by the top, and the sand box is held up, so the shape comes out from the sand mold. At this time, the sand has been tightened and can be removed. Then make the drawing rod drop, the molding machine back to the starting state, and the molding completes a cycle.

Ⅱ. The advantages and disadvantages of the machine:

1. Advantages:

① For small parts with various degrees of complexity, it can meet the process requirements;

② The machine structure is compact and simple. Easy maintenance, good rigidity;

③ Dust cover is used everywhere on piston and guide rod.

2. Shortcomings;

① small compression force, large percussion noise, high labor intensity;

(2) Using the distribution valve sequence control, it is impossible to repeat a certain intermediate process, and it is impossible to carry out a certain process alone, which brings trouble to the operation and maintenance;

③ The drawing cylinder and the drawing frame require high parallelism, which brings difficulties to installation and adjustment.

|

Model

|

Z145K1

|

Z146K

|

Z148C

|

Z148D

|

Z1410E

|

Z1410Ec

|

Z1412

|

|

Maximum size of sand mold (mm)

|

500×400×200

|

630×500×250

|

800×600×250

|

800×630×350

|

1000×800×350

|

1000×800×450

|

1200×1000×400

|

|

Mold opening stroke (mm)

|

200

|

250

|

230

|

350

|

350

|

450

|

400

|

|

Compaction stroke (mm)

|

170

|

180

|

130

|

180

|

200

|

200

|

200

|

|

Jolting capacity (kg)

|

300

|

400

|

400

|

600

|

1350

|

1500

|

1700

|

|

Compacted piston diameter (mm)

|

380

|

420

|

550

|

570

|

650

|

700

|

800

|

|

Vibrating cylinder diameter (mm)

|

150

|

200

|

230

|

230

|

360

|

400

|

420

|

|

Distance from pressure plate to jolt table (mm)

|

568

|

498

|

550

|

630

|

794

|

900

|

900

|

|

Mechanized productivity (box/h)

|

60-80

|

60

|

60

|

60

|

50

|

50

|

50

|

|

Overall dimension (mm)

|

950×600×1680

|

1080×700×1988

|

1730×900×1980

|

1335×975×2050

|

1765×1231×2620

|

1360×1530×2765

|

1740×1530×2975

|

|

Machine weight (kg)

|

1480

|

1570

|

3800

|

5000

|

7600

|

7000

|

10000

|

Q1 How to choose the right size machine?

A1Tell us the process and parameters, we help you select the type.

Q2 Can the machine be customized?

Q3 How to debug equipment?

A4 We have a number of professional installation teams, can provide overseas installation services, engineers can also come to you to guide the installation and commissioning.

Q5 How long is the warranty? What does it contain?

A1Tell us the process and parameters, we help you select the type.

Q2 Can the machine be customized?

A2 We will provide the most appropriate solution.

Q3 How to debug equipment?

A3 The debugging of the equipment is completed before leaving the factory. PLC has remote debugging function, and engineers cancome to your factory for debugging.

Q4How to install the complete set of equipment?

A4 We have a number of professional installation teams, can provide overseas installation services, engineers can also come to you to guide the installation and commissioning.

Q5 How long is the warranty? What does it contain?

A5 Warranty period of one year, one year non-human damage of the main parts free replacement, not including consumer parts.

Hot Searches