- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

58*3*5m

-

Weight:

-

1500 KG

-

Machinery Function:

-

Making frozen french fries

-

Output product name:

-

Potato Chips

-

Product name:

-

complete frozen french fries production line/potato french

-

Material:

-

Stainless steels

-

Capacity:

-

100-1000kg/h

-

Advantages:

-

Easy Operation High Efficiency

-

Package:

-

Standard Packaging

-

Color:

-

Stainless Steel Original Color

-

Size:

-

Stainless Steel Original Size

-

Brand:

-

Tinwing

-

Characteristic:

-

Excellent performance

Quick Details

-

Brand Name:

-

Tinwing

-

Place of Origin:

-

Shandong, China

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

58*3*5m

-

Weight:

-

1500 KG

-

Machinery Function:

-

Making frozen french fries

-

Output product name:

-

Potato Chips

-

Product name:

-

complete frozen french fries production line/potato french

-

Material:

-

Stainless steels

-

Capacity:

-

100-1000kg/h

-

Advantages:

-

Easy Operation High Efficiency

-

Package:

-

Standard Packaging

-

Color:

-

Stainless Steel Original Color

-

Size:

-

Stainless Steel Original Size

-

Brand:

-

Tinwing

-

Characteristic:

-

Excellent performance

Products Description

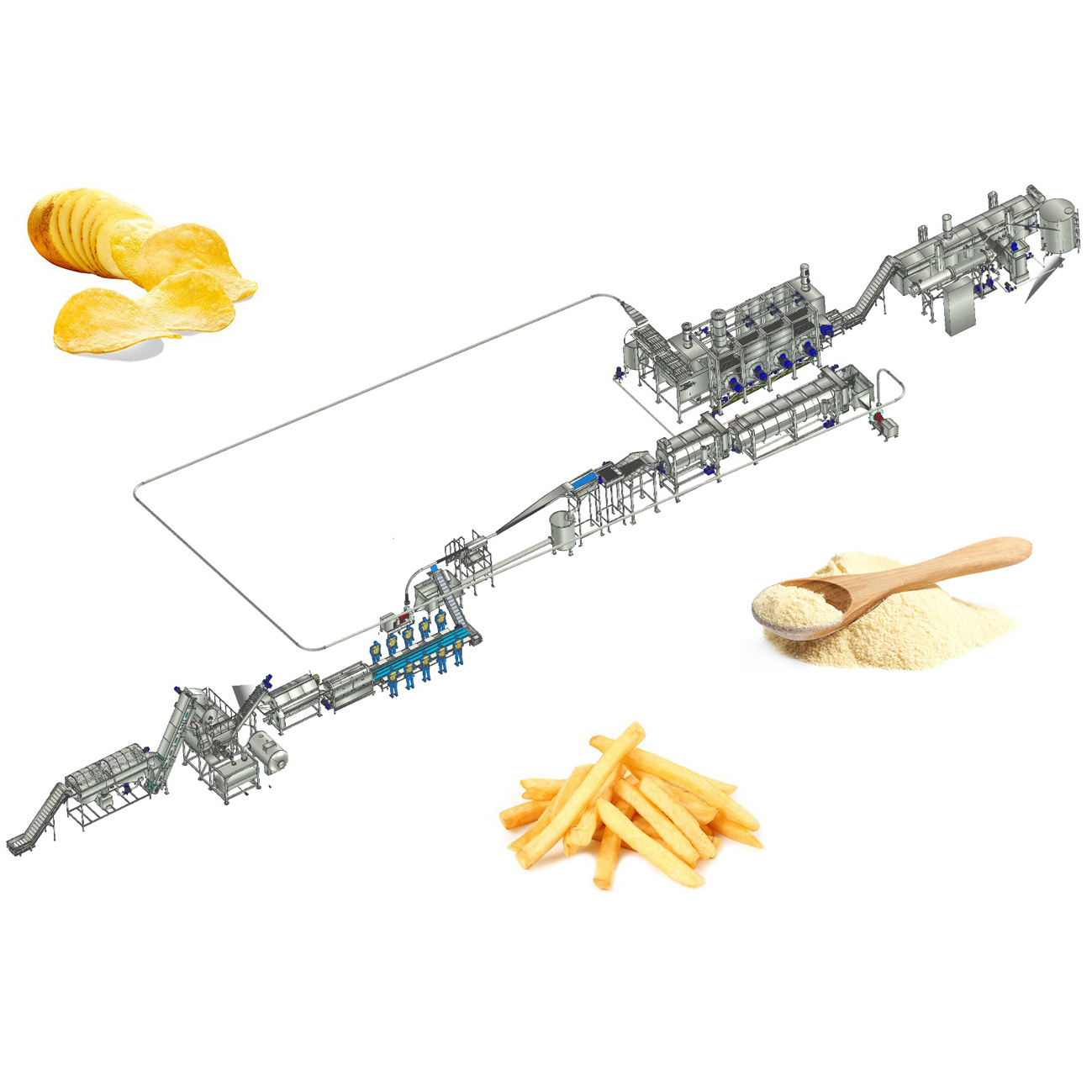

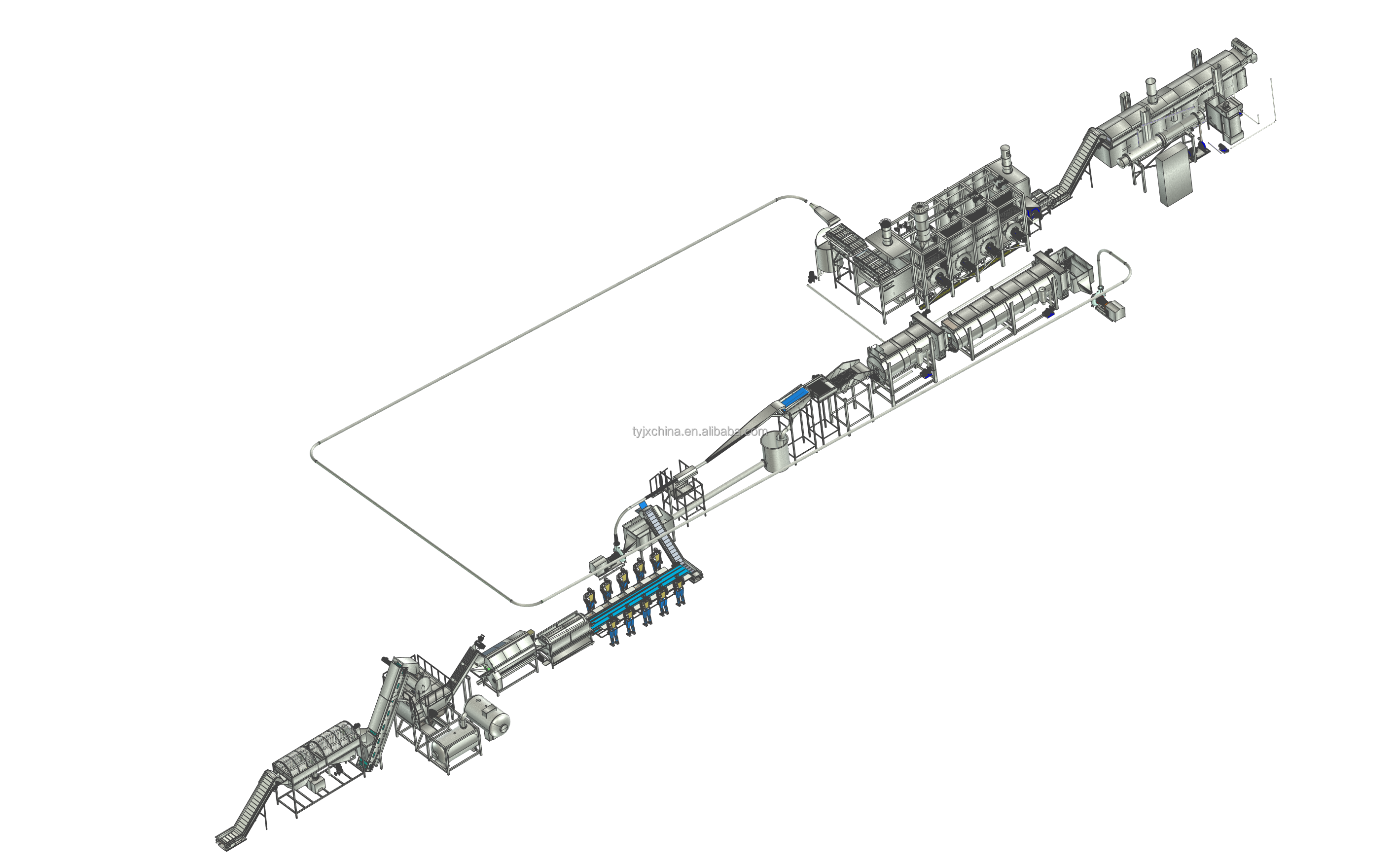

French Fries Production Line

The production line consists of steam peeler, hydro cutter, blancher, drver, fryer, deoiling machine, freezeland packing machine.

Product capacity is from 2-3 tons per hour to 5-6 tons per hour.

lt has a maximum automation and achieves continuous and large-scale production.

Work-flow

Equipment details

Hydro cutting machine

Blanching machine

Short strip screening machine

Drying machine

Frying machine

Freezer

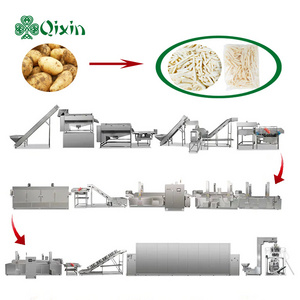

Technological Process

Process Description .

1.

Loading and conveying

2.Stone cleaning machine: remove stone and soil attached to the surface of the potato.

3.

Steam peelers: Operate steam equipment to quickly remove the skin of potatoes.

4.

Roller cleaning machine: the potato surface residue potato skin and starch clean away.

5.

Manual selection table: pick out the broken potatoes and cut the potatoes that are too large.

6.

Water knife cutting: Cut the potatoes into strips according to the established size standards.

7.

Wafer picker: Screen out the potato strips that do not meet the standard size.

8.

Blanching: Boil the potato strips at the right temperature and remove the starch from the surface of the potato strips.

9.

Color protection: This process keeps the fries from changing color for at least two years.

10.

Remove water to dry: Remove water from the surface of the potato strips.

11.

Fry machine: Fry potato chips, so that the French fries outside crisp inside.

12.

Air cooling 、quick freezing and

package.

Specification

|

No.

|

Model

|

Capacity/kg

|

Type

|

Heating methord

|

|

1

|

TW-100

|

100

|

Batch type/Continuous

|

Gas,Electric,Steam,Diesel

|

|

2

|

TW-200

|

200

|

Continuous

|

Gas,Electric,Steam,Diesel

|

|

3

|

TW-500

|

500

|

Continuous

|

Gas,Electric,Steam,Diesel

|

|

4

|

TW-1000

|

1000

|

Continuous

|

Gas,Electric,Steam,Diesel

|

|

5

|

TW-2000

|

2000

|

Continuous

|

Gas,Electric,Steam,Diesel

|

|

6

|

TW-3000

|

3000

|

Continuous

|

Gas,Electric,Steam,Diesel

|

|

7

|

TW-5000

|

5000

|

Continuous

|

Gas,Electric,Steam,Diesel

|

Product packaging

Hot Searches