- Product Details

- {{item.text}}

Quick Details

-

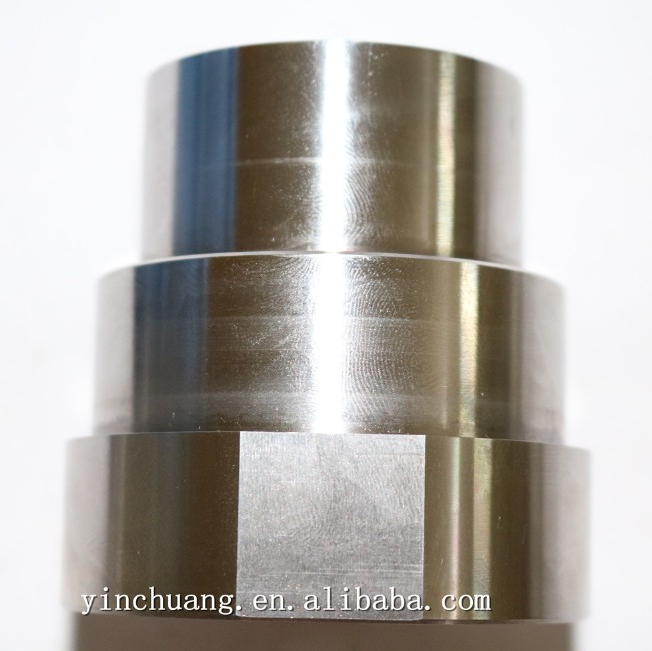

Material:

-

Tungsten Carbide

-

Design software:

-

AutoCAD/Solidworks/UG

-

Experience:

-

Over 10 years

-

Product Name:

-

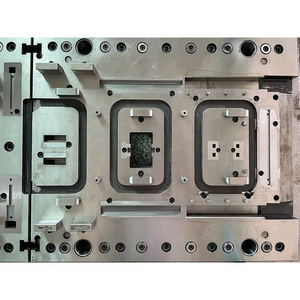

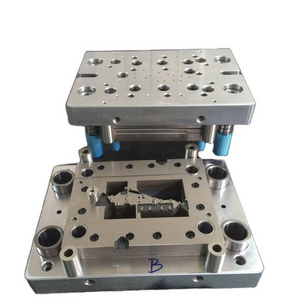

Tablet Press Mould

-

Certification:

-

ISO9001:2008

-

Type:

-

Machining Services

-

Surface treatment:

-

Polishing

Quick Details

-

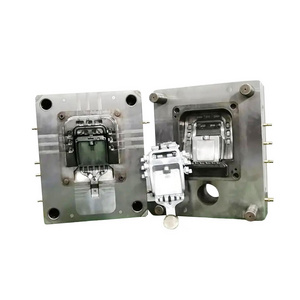

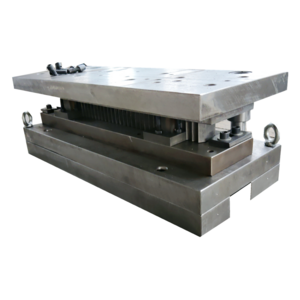

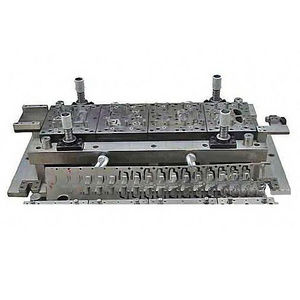

Shaping Mode:

-

Punching Mold

-

Place of Origin:

-

Guangdong, China

-

Tolerance:

-

0.001mm

-

Material:

-

Tungsten Carbide

-

Design software:

-

AutoCAD/Solidworks/UG

-

Experience:

-

Over 10 years

-

Product Name:

-

Tablet Press Mould

-

Certification:

-

ISO9001:2008

-

Type:

-

Machining Services

-

Surface treatment:

-

Polishing

The advantages Of Yinchuang Tungsten Carbide Products:

- resist high temperatures

- withstand high pressure

- guarantee long tool life and high repeated accuracy

- A long tool life reduces production costs

- Accuracy can reach tolerance ±0.001mm.

- The surface mirror polished.

|

Hardness |

45-75 HRC or Depend on the material |

|

Heat treatment |

Available |

|

Service |

Made-to-order |

|

Surface treatment |

TiCN, TiN, Aitain, Ticrn, nitriding , Black oxygened, Black coating etc available |

|

Closest tolerance |

+ - 0.001mm |

|

Polishing |

close to Ra0.2 |

|

processing technology |

Die polished, Polishing, Plating titanium, Lettering, Wire EDM, Electro-discharge machining, Titanize, Heat treatment, Fast wire cutting, Slow wire cutting, Head annealing, Sintering. |

About Yinchuang Precision Mold Parts Co.Ltd

Quality is life, user is god.

- Our company was established in 2005 ,which have a high reputation.

- As a leading manufacturer ,we are specialized in producing tungsten carbide (WC) mold components and mechanical parts

- We use advanced production equipment, including precision measuring instruments , high quality grinding, wire EDM cutting, professional production team.

- Delivery can be achieved 1 day.

Our products including the following:

Powder metallurgy dies:

- Ferrous metal moulds: gear finished die,sizing die,automobile parts,motor driven tool parts,etc.

- Magnaglo moulds: E shape dies,U shape dies,PM shape dies,G shape dies,etc.

- Tungsten carbide moulds: wire-drawing die,indexable inserts dies,mining tools dies,squeezing die,teel die,etc.

Kinds of tungsten carbide TF products:

- Tungsten carbide nonstandard dies: cold heading dies,battery dies,carbide blanking dies,tretching die,etc.

- Tungsten carbide wear parts: carbide rollers,carbide gauge.

Accept all trading manners

EXW, FOB, CIF, DDP, DDU.etc

Accept any kinds of payment terms

TT, L/C, D/P, O/A.etc

Please inquiry us as below.