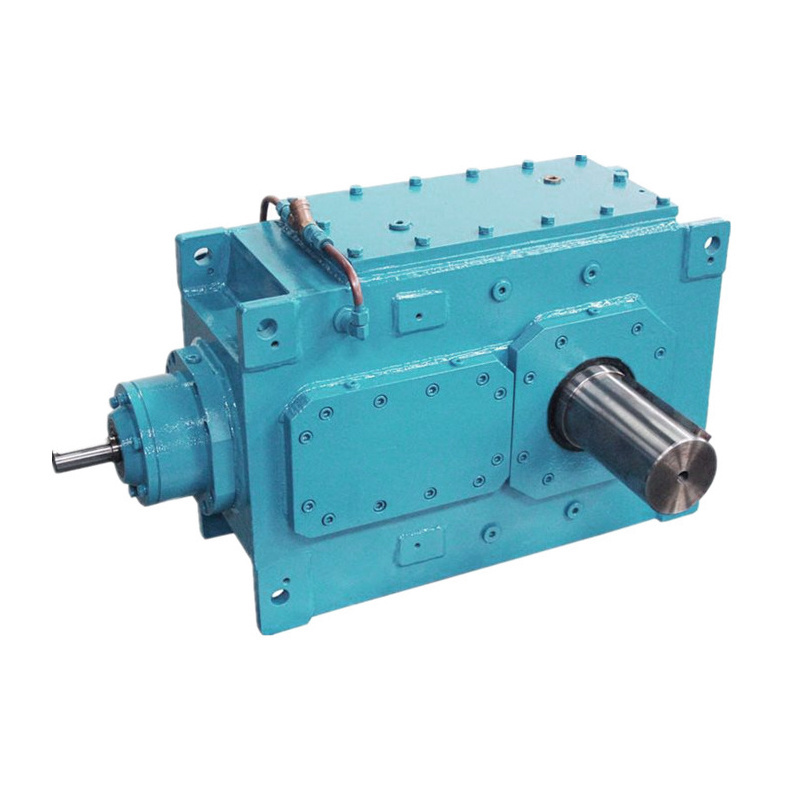

- Product Details

- {{item.text}}

Quick Details

-

Output Speed:

-

01-1200 rpm

-

Weight (KG):

-

25

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

ever-power

-

Model Number:

-

P2.V,P3.V,P4.V

-

Rated Power:

-

Top to 4800 Kw

-

Color:

-

Customer Requests

-

Application:

-

Mining etc.

-

Material:

-

High Strength Cast Iron

-

Mount Position:

-

Horizontal/Vertical/Horizontal Design Without Feet

-

Certificate:

-

CCC ISO

-

Output Shaft Design:

-

Solid Shaft/Hollow Shaft/Hollow Shast For Shrink Disk

Quick Details

-

Gearing Arrangement:

-

Bevel / Miter

-

Output Torque:

-

Top to 952000 N.m

-

Input Speed:

-

750-1500 rpm

-

Output Speed:

-

01-1200 rpm

-

Weight (KG):

-

25

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

ever-power

-

Model Number:

-

P2.V,P3.V,P4.V

-

Rated Power:

-

Top to 4800 Kw

-

Color:

-

Customer Requests

-

Application:

-

Mining etc.

-

Material:

-

High Strength Cast Iron

-

Mount Position:

-

Horizontal/Vertical/Horizontal Design Without Feet

-

Certificate:

-

CCC ISO

-

Output Shaft Design:

-

Solid Shaft/Hollow Shaft/Hollow Shast For Shrink Disk

Products Description

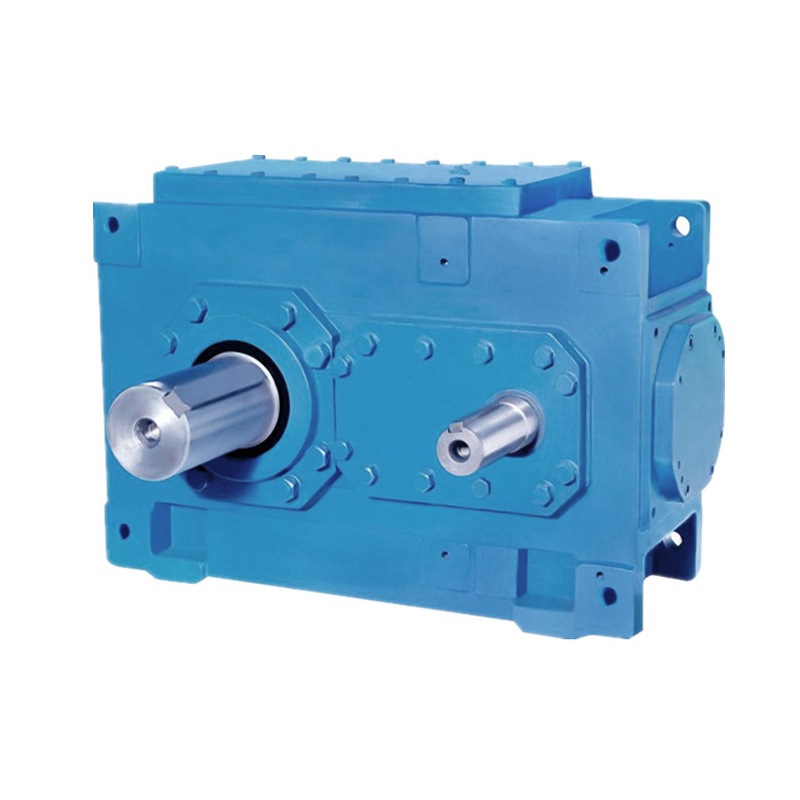

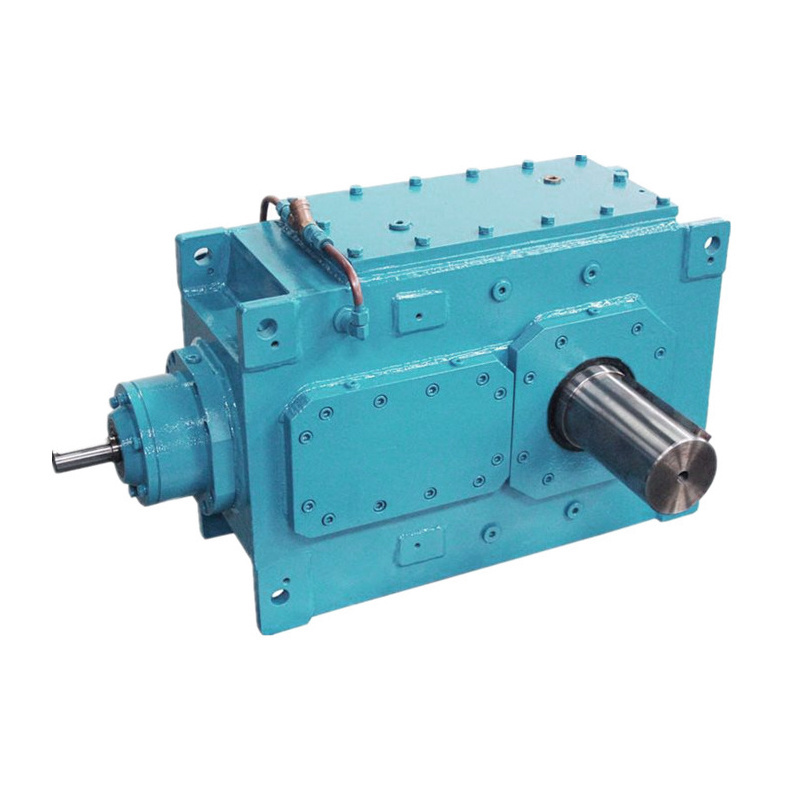

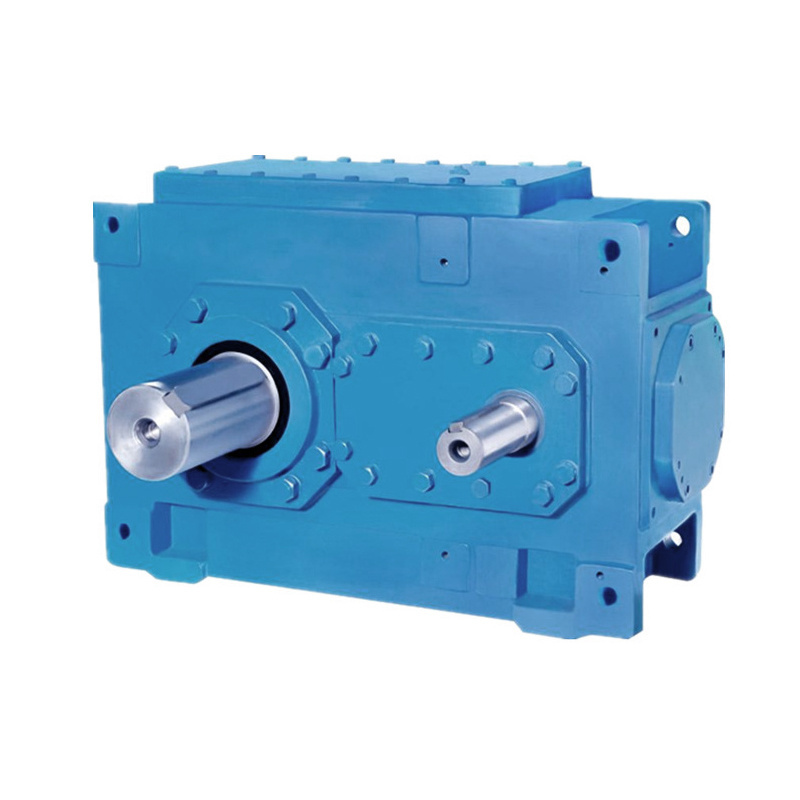

HB standard industrial gearbox

1. Adopting the structure of the sound absorption box, the large surface area of the box body and the large fan, cylindrical gear and spiral gear adopt advanced gear grinding technology, so that the temperature rise, noise reduction, and operation reliability of the whole machine are improved. The power increases.

2. The H and B series industrial gearboxes adopt a general design scheme to realize a universal box for parallel shafts and right-angle shafts. The types of parts are reduced and the specifications and models are increased.

3. H and B standard industrial gearboxes have 3~26 specifications. There are 1-4 stages of deceleration transmission, and the speed ratio is 1.25-450.

4. Installation method: base installation, hollow shaft installation, swing base installation, torque arm installation.

5. Input mode: motor connection flange, shaft input.

6. Output mode: solid shaft with flat key, hollow shaft with flat key, hollow shaft connected by expansion plate, hollow shaft connected by spline, solid shaft connected by spline and solid shaft connected by flange.

7. Backstop can be equipped according to customer requirements. Combine with R and K series to get larger speed ratio.

Technical Parameters:

Speed ratio range: H series 1.25-450, B series 5-400

Torque range: H series 2-900 kNm. B series 5.8-900 kNm

Power range: H series 4-5000 kW, B series 2.8-3000kW

Overview of H and B series industrial gearboxes

1) H and B gearboxes adopt general design schemes, which can be transformed into industry-specific gearboxes according to customer needs.

2) Achieve parallel shaft, right-angle shaft, vertical, Chen Bu-type general box, reduce the types of parts and increase the specifications and models.

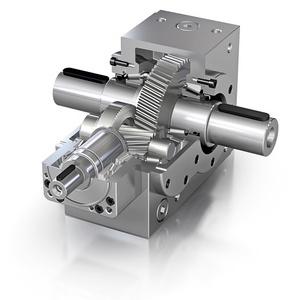

3) Adopting the structure of the sound-absorbing box, the large surface area of the box and the large fan, the cylindrical gear and the spiral cone-i wheel all adopt advanced gear grinding technology, so that the temperature rise of the whole machine, the reduction of noise, and the reliability of operation are improved. , The transmission power increases.

4) Input mode: motor connection flange, shaft input.

5) Output mode: solid shaft with flat key, hollow shaft with flat key, hollow shaft connected by expansion plate, hollow shaft connected by spline, solid shaft connected by spline and solid shaft connected by flange.

6) Installation method: horizontal, vertical, swing base, torsion arm type.

7) 11, B series production. nIII has 1^-26 type specifications, reduction transmission stages are 1-4, speed ratio 1.25 -450, and CR, K, 5 series combination to get a larger speed ratio

|

Ratio

|

25-4000

|

|

Output speed

|

1.7-1200r/mkin

|

|

Output Torque

|

Up to 470000Nm

|

|

Motor power

|

2.52-5366KW

|

|

Mounted Form

|

HORIZONTAL MOUNTING, VERTICAL MOUNTING,AXIS MOUTING, SHRINK DISK MOUTING

|

For more models or customization, please click here!

Click on the picture below for details

Related Products

Hot Searches