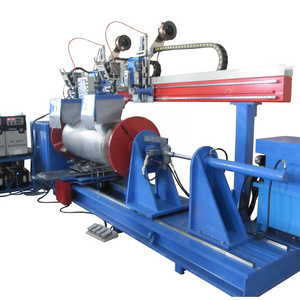

The large frame eliminates vibration, improves the service life of IDE, and improves the economy and practicability of the machine. The operating space is very wide, and the movable bolster can be moved out of the frame to fix the mold.

The C-frame provides the maximum rigidity and minimum deflection to provide precise parts and long tool life. Steel welded frame,

compact with high rigidity and small deformation. Thick plates and large columns provide a stable platform for your demanding

applications.

compact with high rigidity and small deformation. Thick plates and large columns provide a stable platform for your demanding

applications.