- Product Details

- {{item.text}}

Quick Details

-

Year:

-

2024

-

Voltage:

-

380

-

Dimension(L*W*H):

-

6800*900*1800

-

Motor Power (kW):

-

15

-

Weight (T):

-

3

-

Machine Type:

-

Iron Working Machine

-

Function:

-

Angle Steel Punching and Cutting

-

Keyword:

-

Automatic Punch Shear Machine

-

Cutting Material:

-

pipe tube Angle Channel Steel Plate

-

Application:

-

Sheet Metal Industry

-

Product name:

-

pipe punching and shearing machine

-

Shearing Mode:

-

Dual-blade Shearing

-

Advantage:

-

automatic

Quick Details

-

Nominal Force (kN):

-

2000

-

Place of Origin:

-

anhui

-

Brand Name:

-

Daramco

-

Year:

-

2024

-

Voltage:

-

380

-

Dimension(L*W*H):

-

6800*900*1800

-

Motor Power (kW):

-

15

-

Weight (T):

-

3

-

Machine Type:

-

Iron Working Machine

-

Function:

-

Angle Steel Punching and Cutting

-

Keyword:

-

Automatic Punch Shear Machine

-

Cutting Material:

-

pipe tube Angle Channel Steel Plate

-

Application:

-

Sheet Metal Industry

-

Product name:

-

pipe punching and shearing machine

-

Shearing Mode:

-

Dual-blade Shearing

-

Advantage:

-

automatic

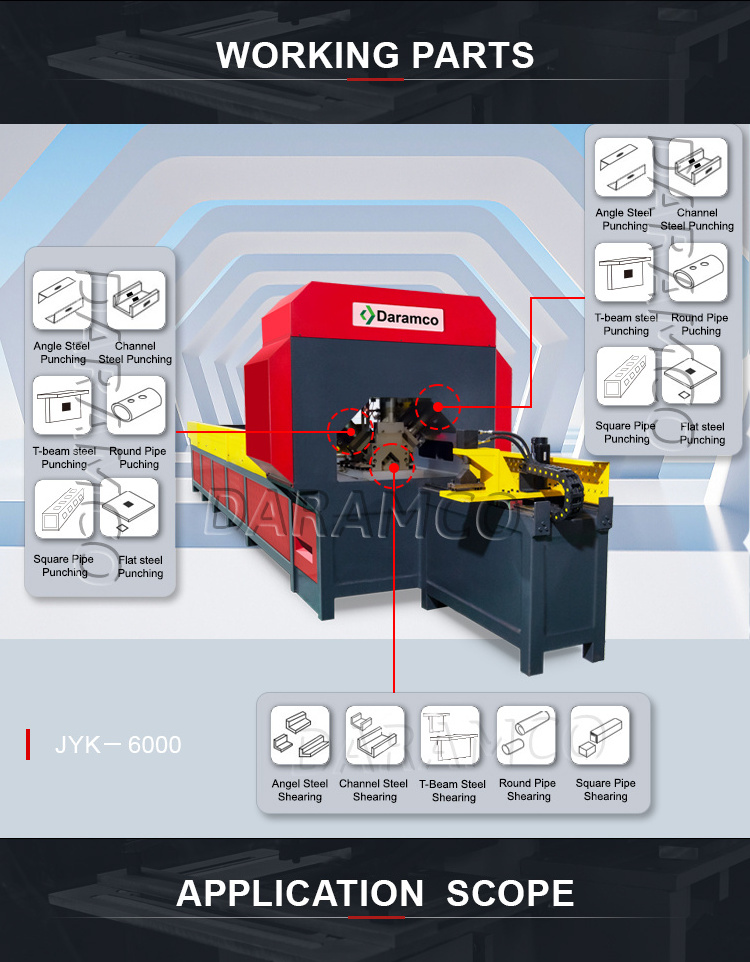

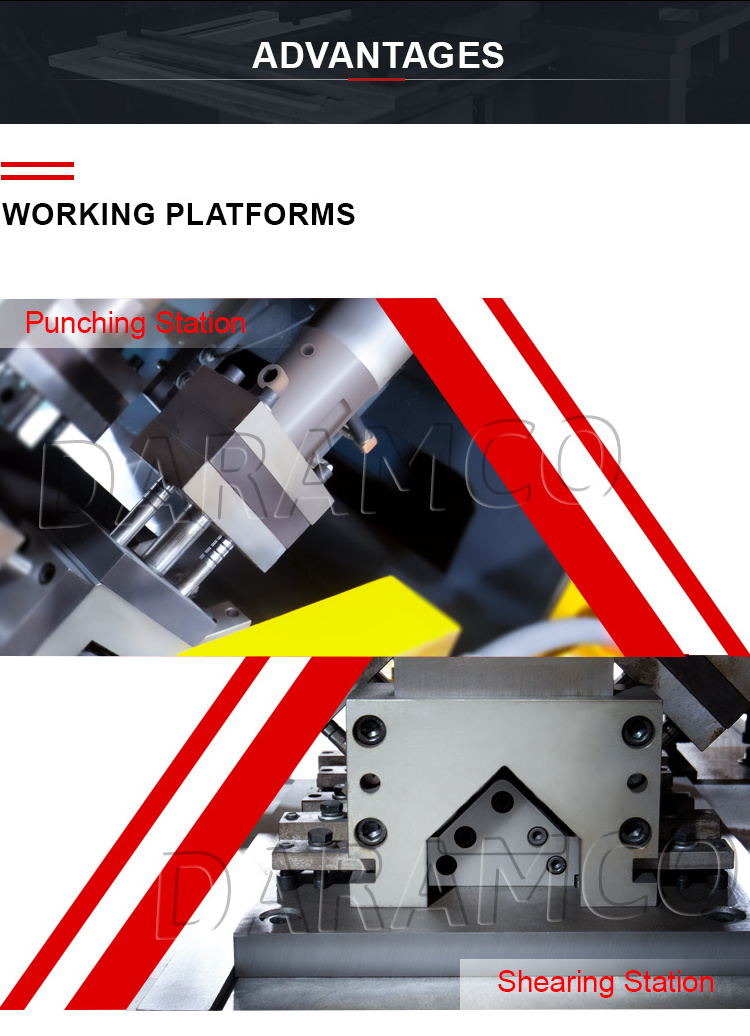

Hydraulic transmission, CNC touch screen and PLC control, abnormal shutdown alarm

function. It can punch, cut and form flat steel, square pipe, round pipe, Angle steel, channel

steel, T-shaped steel and other profiles. Automatic drawing, automatic feeding, automatic

punching,cutting, forming. It has the characteristics of fast processing speed, high

positioning accuracy, combined fast processing, user-friendly operating system,

convenient and simple.

Profile steel ironworker machine through the CNC system can be stainless steel pipe, iron, PVC, gold-plated steel, zinc steel guardrail, balcony fence and aluminium alloy pipe automatic punching and cutting. It is suitable for the processing of anti-theft mesh, guardrail, shelf, angle iron, aluminium profile, bridge fence, iron frame bed, ladder frame and other products. The equipment is widely used to meet the diversified and customised processing requirements of angle steel, channel steel, T-beam steel, square pipe, round pipe, flat steel and other steel profiles.

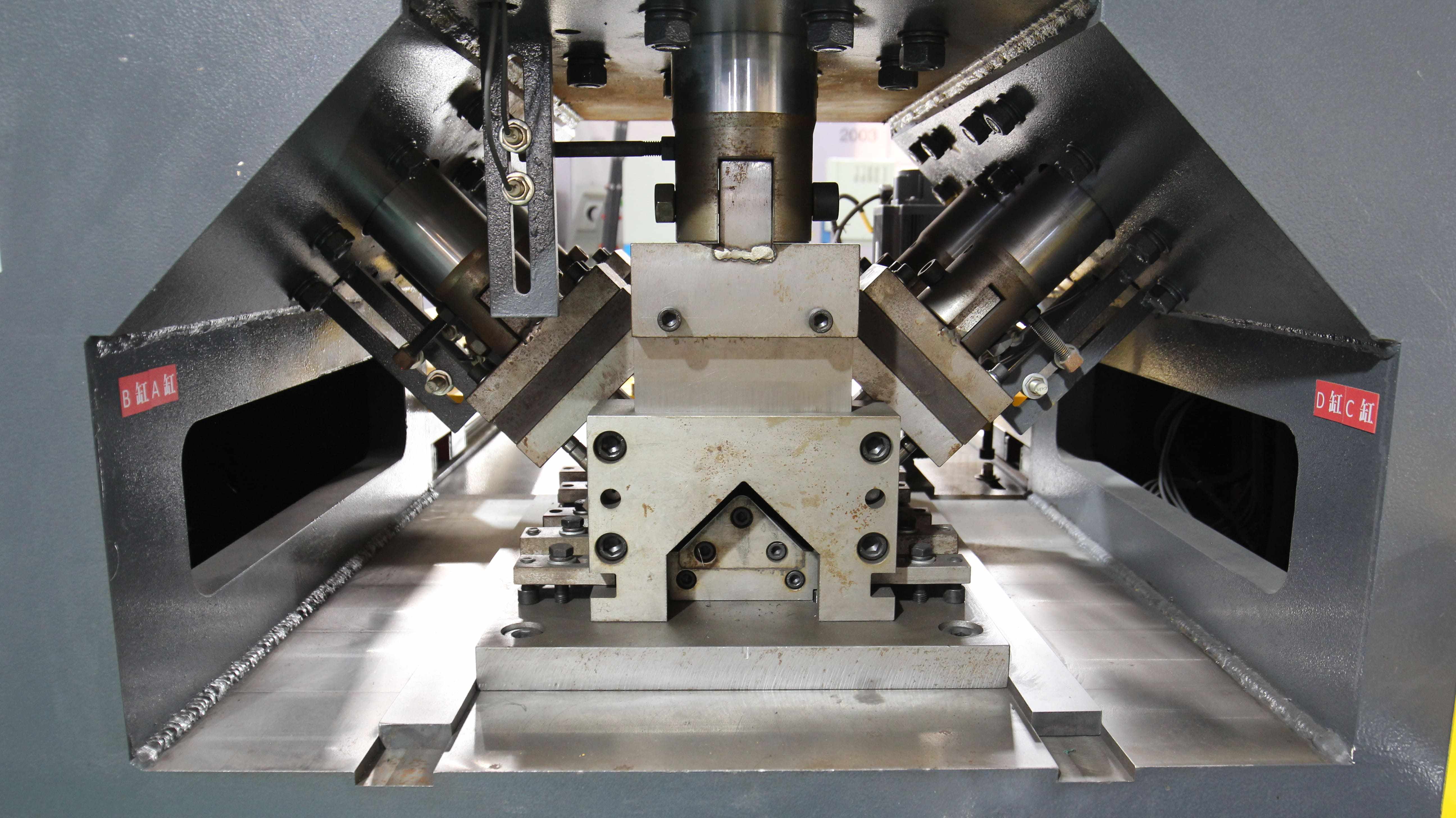

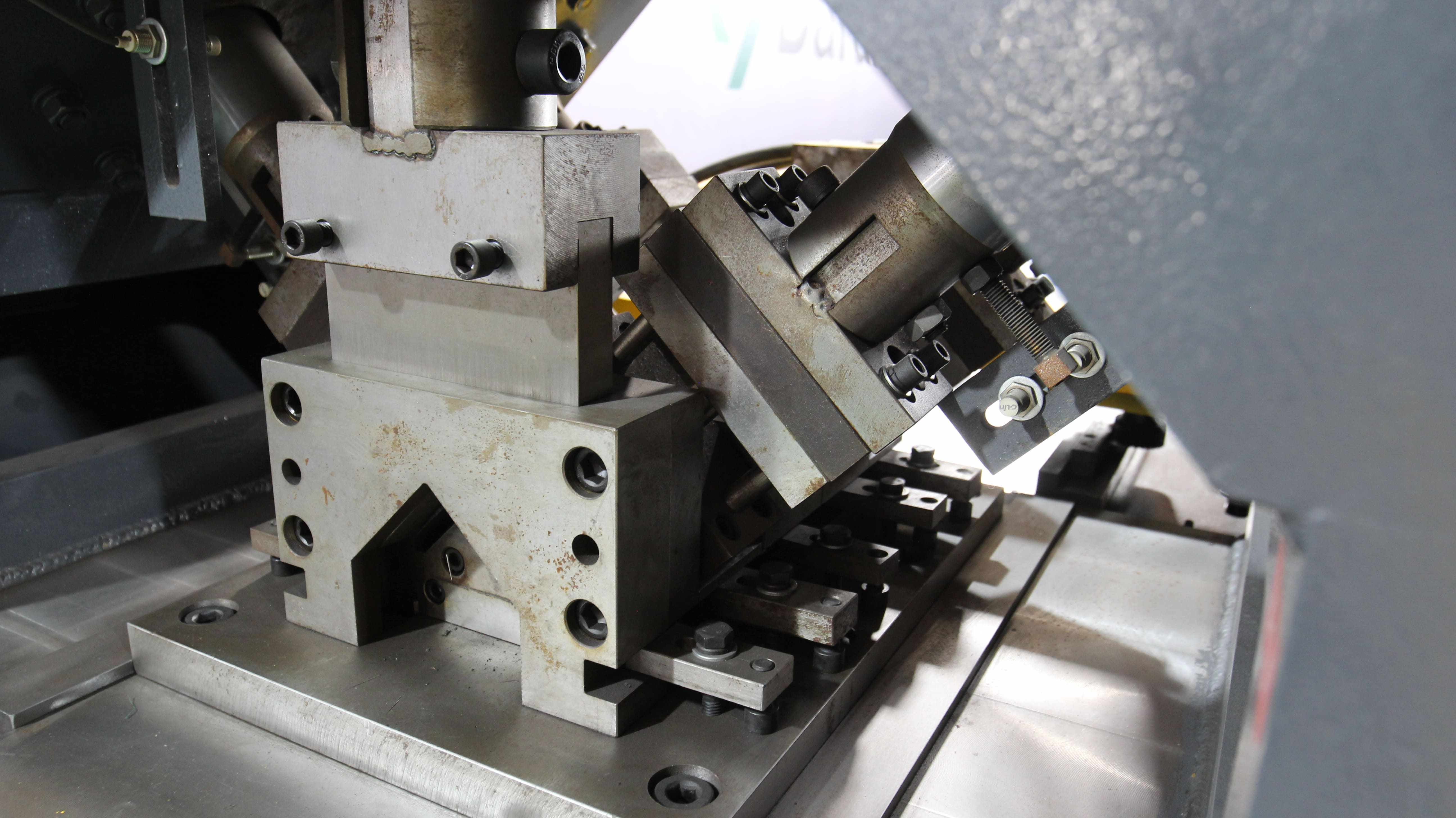

The machine has both punching and shearing functions.it can automatically punch and

shear the shape of channel steel, angle steel, round pipe, square pipe, T-beam, flat steel.

The number of hydraulicoil oil cylinders, punching specifications and shear function can

be customised to meet diversified processing needs..The punching size and specification

can be customised, and the mould can be replaced flexibly, so as to realise multi-purpose

and cost saving. The moulds are designed and developed by DARAMCO, made of DC53

material, which is wear-resistant and hard, easy to replace and improve the working efficiency.

The equipment adopts touch screen and PLC control, abnormal shutdown that is the alarm,

It's very clear to see the fault message, Quick resolution of after-sales problems.

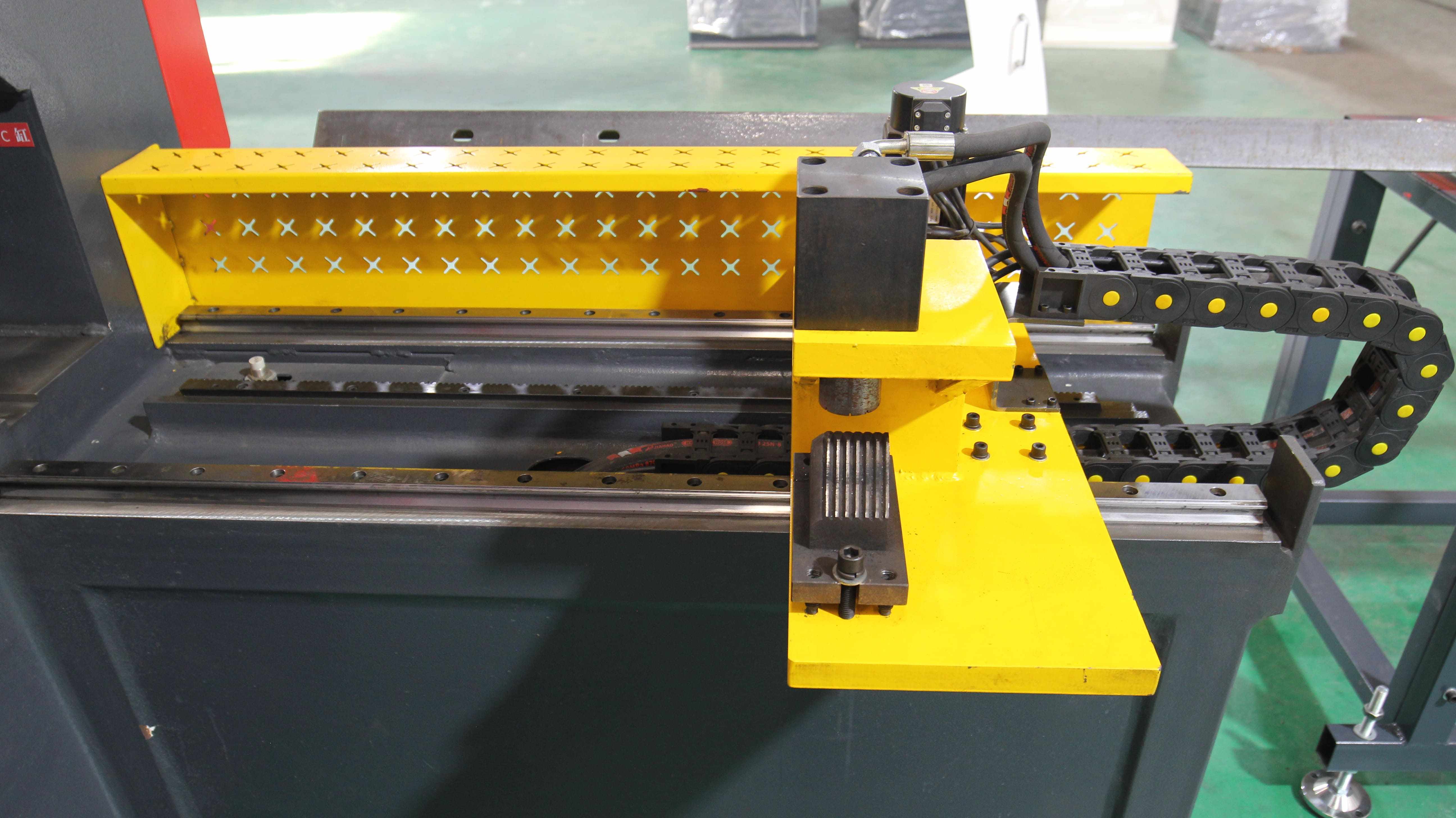

Visualised CNC system control, easy to operate, high precision. After Manual feeding, the

equipment automatically pulls, feeds, locates and sets the distance, punches and shears,

realising one-time forming of the workpiece.

The front CNC control device cooperates with the machine feeding device to perfectly

overcome the problem of material waste caused by insufficient processing distance of

the ast machining of a single workpiece, greatly reducing material waste and improving

production efficiency, thus greatly improving the economic benefits of the enterprise

.

|

Name

|

Specifications

|

Unit

|

Remarks

|

|

Stroke Length

|

6050

|

mm

|

Customized

|

|

Maximum punching diameter

|

φ20-φ60

|

mm

|

|

|

Maximum punching and shearing thickness

|

4-16

|

mm

|

|

|

Cylinder stroke

|

100-250

|

mm

|

Customized

|

|

Stroke times

|

10-40

|

cp/m

|

|

|

Maximum feeding speed

|

800

|

mm/s

|

|

|

Single hydro-cylinder pressure

|

20-160

|

T

|

Customized

|

|

Electric motor

|

5.5-18.5

|

KW

|

|

|

Variable stroke plunger pump

|

10-80MCY14

|

L

|

|

|

Servo motor

|

0.75~3

|

N/m㎡

|

|

|

Processing material strength

|

≤450

|

mm

|

|

|

Machine dimensions

|

6800*900*1800

|

mm

|

Length*Width*Height

|

|

Auxiliary frame size

|

2500*700*700

|

mm

|

Length*Width*Height

|

|

Type of profile

|

Specification range corresponding to each stamping tonnage (Unit: mm)

|

|

Square pipe

|

≤160*160*8

|

|

Round pipe

|

≤φ120*8

|

|

Angle steel

|

≤160*160*12

|

|

Channel steel

|

≤200*75*9

|

|

T-shaped steel

|

≤160*160*16

|

Hot Searches