- Product Details

- {{item.text}}

Quick Details

-

Applied to Materials:

-

plastic film, Paper ,BOPP, foil, Opp ,Alumium,CPP ,PET ,Fabric, etc

-

Coating width:

-

600mm-1900mm

-

Mechanical speed:

-

80-180m/min

-

Coating method:

-

Comma Blade, Rod Blades, Anilox gravure roller, Mayer Bar, etc

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

coating laminating:

-

Adhesive PVC BOPP Tape Heat Transfer Paper Film

-

Multi-Functional:

-

coating, wet laminating, printing (optional)

-

Applied to Materials:

-

plastic film, Paper ,BOPP, foil, Opp ,Alumium,CPP ,PET ,Fabric, etc

-

Coating width:

-

600mm-1900mm

-

Mechanical speed:

-

80-180m/min

-

Coating method:

-

Comma Blade, Rod Blades, Anilox gravure roller, Mayer Bar, etc

Coating Laminating Machine

Multi-functional Comma Blade Coating Adhesive PVC BOPP Tape Heat Transfer Paper Film Coating Machine with Explosionproof Oven

Why Choose Us

(1)

OEM or Customizable Coating Laminating Machines from 2000.

(2) “Quality is our Culture.” QC team to strive to provide superior-quality machines.

(3) Machine performance inspection in local Customer’s factory is available.

(4) Machine operation training, technician dispatch is available.

(5) Satisfactory service with professional English-spoken workers.

(6) One year guarantee, Lifetime service.

(7) 100% Recommended by old customers.

(8) Certificate ISO, CE, SGS.

(9) “QUALITY AGREEMNT”, “REFUND MONEY AGREEMENT”

(10) Payment by T/T, L/C at sight, Western Union, Paypal, Moneygram, Cash.

The Complete Production Line Machines and technology for Hot Stamping Foil can be supplied.

(2) “Quality is our Culture.” QC team to strive to provide superior-quality machines.

(3) Machine performance inspection in local Customer’s factory is available.

(4) Machine operation training, technician dispatch is available.

(5) Satisfactory service with professional English-spoken workers.

(6) One year guarantee, Lifetime service.

(7) 100% Recommended by old customers.

(8) Certificate ISO, CE, SGS.

(9) “QUALITY AGREEMNT”, “REFUND MONEY AGREEMENT”

(10) Payment by T/T, L/C at sight, Western Union, Paypal, Moneygram, Cash.

The Complete Production Line Machines and technology for Hot Stamping Foil can be supplied.

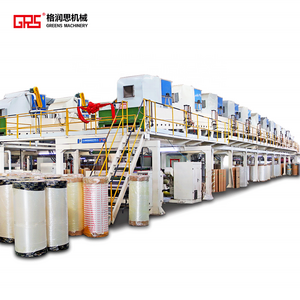

Machine Photos

OEM Customizable Coating Laminating Machine

Application

Coating & Laminating

Wet Laminating

Computerized High-speed Wet Laminating Machine is suitable for coating or laminating the materials of transfer aluminizing paper,

transfer laser cards, metalized gold or silver cards, etc. PE protective film, all kinds of adhesive sticker tape, thermal

insulation materials, XPE Foams, label sticker, etc coating laminating.

Film coating

: release film, protective film, scratch-resistant film. Hot stamping film, laser holographic film, aluminized

Wet Laminating

Computerized High-speed Wet Laminating Machine is suitable for coating or laminating the materials of transfer aluminizing paper,

transfer laser cards, metalized gold or silver cards, etc. PE protective film, all kinds of adhesive sticker tape, thermal

insulation materials, XPE Foams, label sticker, etc coating laminating.

transfer, thermal transfer film, coating and other coating products, production, BOPP,CPP ,PET ,PP ,PVC tape, foam stickers, PE,

non-woven, PU coating, Metallic yarn coating.

Paper coating : It’s suitable for the production of paper, white cardboard, duplex cardboard, synthetic paper, PP paper, PET

sheet, high light waterproof photo paper, matte photo paper, cast coated photo paper, RC high glossy photo paper, carbonless

paper, PP Synthetic Paper and other high-tech information industry paper.

Foil coating : Household Foil, Pharmacy Foil, Cold Forming Medicine Package Foil, Food Soft Packing Foil, Container Foil, Beer

Mark, Air-conditioner Foil, Decoration Foil

Attention Please

Since all the Coating Laminating Machines are customized. Please send us the detail Coating Specification or Coating Process

Requirement, so that we can offer the exact OEM coating machine. Including the main points as below

1 the base material

2 the width

3 unwinding and rewinding diameter

4 coating material

5 wet coating amount

6 specification of laminating material (if laminating function is needed)

6 heating method

7 coating speed

8 oven length

9 Application of final products

Since all the Coating Laminating Machines are customized. Please send us the detail Coating Specification or Coating Process

Requirement, so that we can offer the exact OEM coating machine. Including the main points as below

1 the base material

2 the width

3 unwinding and rewinding diameter

4 coating material

5 wet coating amount

6 specification of laminating material (if laminating function is needed)

6 heating method

7 coating speed

8 oven length

9 Application of final products

Products Description

Spec.:

-Overall machine adopts frequency motors control, adopt JAPANESE MITSHUBISHI PLC to automatic control tension of unwinding,

coating, traction, rewinding , and man machine interface touch screen to control and display to improve machine tension

reliability.

- Independent unwinding frame, adopt magnetic powder auto-control tension

- Gravure coating method, coating doctor blade shaft adopt heavy double shaft machine independent moving, blade adjust by manual

with pneumatic, angle adjust freely, coating quantity depend the mesh of gravure roller, different coating quantity can change

different mesh gravure roller.

- Oven sections independently controlled. Heating adopts electric, hot air intake drying

system, heater outset,heating pipe adopt stainless steel with cooling fin type, adjustable inner cycle air intake and out device,

air intake and outlet with strong air, dry thoroughly.

- Oven inner guide wheel is active synchronous with the mainframe, drive adopt synchronous belt drive guide wheel to assure

synchronous to reduce material stretch and deformation, cylinder pneumatic open oven and film pass operation panel so that worker

can work very easily.

- The tension between coaitng roller and traction steel roller adopt float swing arm by PLC auto-control.

- Auto-length and speed meter device

- Webguide adopts EPC air sensitive register to assure the trimness when rewinding.

- Rewinding and unwinding adopt key type airshaft for easily operating when loading and unloading the material, air shaft take

in/off adopt safety lock type

- High presicion up press traction device, steel roller cooling adopt water cycle to make the film surface more smooth and neat.

to reach good cooling effect.

- Rewinding frame is electric rotation double station, rewinding adopt frequency motor, vector inverter by PLC control.

-Overall machine adopts frequency motors control, adopt JAPANESE MITSHUBISHI PLC to automatic control tension of unwinding,

coating, traction, rewinding , and man machine interface touch screen to control and display to improve machine tension

reliability.

- Independent unwinding frame, adopt magnetic powder auto-control tension

- Gravure coating method, coating doctor blade shaft adopt heavy double shaft machine independent moving, blade adjust by manual

with pneumatic, angle adjust freely, coating quantity depend the mesh of gravure roller, different coating quantity can change

different mesh gravure roller.

- Oven sections independently controlled. Heating adopts electric, hot air intake drying

system, heater outset,heating pipe adopt stainless steel with cooling fin type, adjustable inner cycle air intake and out device,

air intake and outlet with strong air, dry thoroughly.

- Oven inner guide wheel is active synchronous with the mainframe, drive adopt synchronous belt drive guide wheel to assure

synchronous to reduce material stretch and deformation, cylinder pneumatic open oven and film pass operation panel so that worker

can work very easily.

- The tension between coaitng roller and traction steel roller adopt float swing arm by PLC auto-control.

- Auto-length and speed meter device

- Webguide adopts EPC air sensitive register to assure the trimness when rewinding.

- Rewinding and unwinding adopt key type airshaft for easily operating when loading and unloading the material, air shaft take

in/off adopt safety lock type

- High presicion up press traction device, steel roller cooling adopt water cycle to make the film surface more smooth and neat.

to reach good cooling effect.

- Rewinding frame is electric rotation double station, rewinding adopt frequency motor, vector inverter by PLC control.

Final Products Samples

Product Paramenters

|

Model

|

TB-A (Economical type)

|

TB-B (Improvement type)

|

|

|

Apply to raw materials

|

OPP, PET, PVC, PA, CPP film, Aluminum foil and other types of plastic film , fabric and paper, etc.

|

|

|

|

Width of material

|

600mm to 2000mm

|

|

|

|

Functions

|

Coating, Laminating

|

|

|

|

Max. mechanical speed

|

80-180m/min

|

|

|

|

5Max. Speed of laminating

|

50-160m/min

|

|

|

|

Dry oven length

|

5 meters to 35 meters, customizable

|

|

|

|

Operation or control system

|

Operation button panel

|

PLC, touch screen panel

|

|

|

Mode of unwinding and rewinding

|

Single shaft, shaftless unwinding, Or double-station rotary rollers for unwinding, options available

|

|

|

|

Max. Diameter of unwinding and rewinding

|

600mm-1500mm

|

|

|

|

Unwinding brake

|

Magnetic powder brake or air brake

|

|

|

|

Tension controller

|

Automatic constant tension control for unwinding, torque motor or variable frequency motor for rewinding

|

|

|

|

Edge position system

|

E.P.C or L.P.C automatic edge system, control accuracy≤1mm

|

|

|

|

Coating modes

|

Cob-webbing rollers (Anilox roller) coating, Three-roller, steel wire, rod blade, comma blade coating, or anti-comma coating, etc.

|

|

|

|

Heating modes

|

Electric heating ,Conduction Oil heating ,Steaming heating, etc.

|

|

|

|

Oven

|

Arc top-opening door (controlled by pneumatic), explosionproof oven optional

|

|

|

|

Reflector cover

|

Stainless steel

|

|

|

|

Temperature control system

|

PID intelligent temperature controller, temperature control accuracy≤±2℃

|

|

|

Machines Delivered

Hot Searches