- Product Details

- {{item.text}}

Quick Details

-

Power:

-

190kw

-

Dimension(L*W*H):

-

45*6*1.5

-

Weight:

-

9000 kg

-

Safety:

-

button stop

-

strong enginee:

-

190KW

-

useful life:

-

15 Years

-

well price:

-

Manufacture

-

experience:

-

15 years export

-

Pipe Thickness:

-

0.5-2.5mm

-

Pipe making speed:

-

20-100m/min

-

Mojor motor:

-

90KW

-

High frequency power:

-

100KW

-

Pipe diameter:

-

16-63.5mm

Quick Details

-

Pipe Material:

-

Carbon steel

-

Production Capacity:

-

2

-

Place of Origin:

-

Guangdong, China

-

Power:

-

190kw

-

Dimension(L*W*H):

-

45*6*1.5

-

Weight:

-

9000 kg

-

Safety:

-

button stop

-

strong enginee:

-

190KW

-

useful life:

-

15 Years

-

well price:

-

Manufacture

-

experience:

-

15 years export

-

Pipe Thickness:

-

0.5-2.5mm

-

Pipe making speed:

-

20-100m/min

-

Mojor motor:

-

90KW

-

High frequency power:

-

100KW

-

Pipe diameter:

-

16-63.5mm

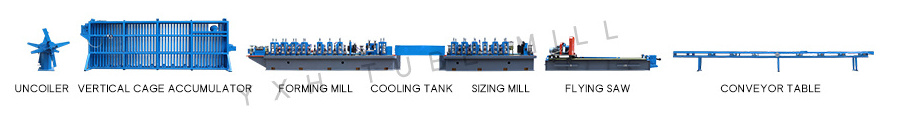

PRODUCT INTRODUCTION

available pipe production range

pipe diameter:

15-50.8

mm;pipe thickness:

0.3-2.2

mm

pipe shape:round,square,rectangle,oval and shaped pipes.

Product Paramenters

|

model

|

Round Pipe

|

|

Square Pipe

|

|

|

|||

|

|

Pipe Dia.

(mm)

|

Pipe Thickness

(mm)

|

Square size (mm)

|

Rectangular size (mm)

|

Pipe Thickness (mm)

|

|||

|

HF16

|

8-25

|

0.2-1.0

|

10*10-20*20

|

10*10-10*30

|

0.2-0.7

|

|||

|

HF28

|

8-50.8

|

0.3-1.8

|

10*10-40*40

|

10*10-20*60

|

0.3-1.5

|

|||

|

HF32

|

15-65

|

0.5-2.5

|

20*20-50.8*50.8

|

10*30-40*60

|

0.5-2.0

|

|||

|

HF45

|

12.7-63.5

|

0.4-2.5

|

10*10-50*50

|

10*10-40*60

|

0.4-2.0

|

|||

|

HF50K76

|

20-76

|

0.6-3.0

|

15*15-60*60

|

10*20-40*80

|

0.6-2.2

|

|||

|

HF60K102

|

28-102

|

0.6-3.0

|

20*20-80*80

|

10*30-60*100

|

0.6-2.5

|

|||

|

HF76K127

|

38-127

|

galvanized steel

0.8-3.0

Iron

0.8-3.5

|

40*40-100*100

|

30*50-80*120

|

galvanized steel

0.8-2.0

Iron

0.8-3.0

|

|||

|

HF165K219

|

63.5-219

|

galvanized steel

1.5-3.0

Iron

1.5-6.0

|

50*50-150*150

|

40*60-100*200

|

galvanized steel

1.5*3.0

Iron

1.5*4.0

|

|||

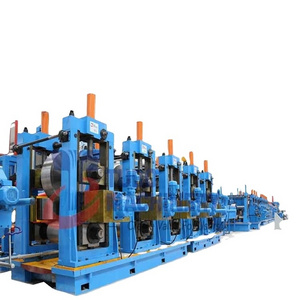

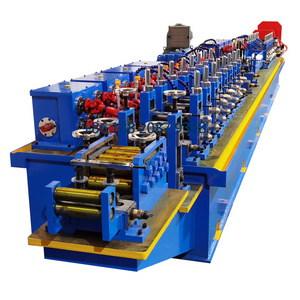

Machine advantage

1. Compared with the ordinary horizontal arch, the needle bearing is faster to replace the mold, easier to disassemble and more stable.

2.Thicker horizon stand make pipe more stable.

3.Fix the steel coil, make the coil better forming, improve the pipe making speed.

Application

The pipes produced by our machine are welded tightly and have strong compression resistance. It is suitable for many kinds of industrial pipe production. For example, liquid transportation: milk, water transportation; automobile exhaust pipe; sanitary pipe, etc.

After Service--Provide service 24 hours*7 days per week

1.Test the tube mill machine before shipment

2.Provide technical guidance relate to use the tube making machine

3.Provide the spare parts at cost price after warranty period

4.Collect the feedback for tube mill machine working

5.Provide long-term technical assistance

6.Offer the professional engineer to help you improve the output ,reduce the waste and decrease the cost.

We use steel wire and wooden frame to fix the pipe making machine;

In addition, used shockproof film to protect the main motors.

We use the container to deliver goods to our customer. Generally speaking, we start at FOSHAN port, but we also can start at other port according to customer's need.

Hot Searches