- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

THERMELT 867 Black HV

-

Type:

-

Hot Melt Adhesives

-

Application:

-

Low pressure molding

-

Raw Material:

-

PA(Polyamide)

-

Features:

-

Water Resistance

-

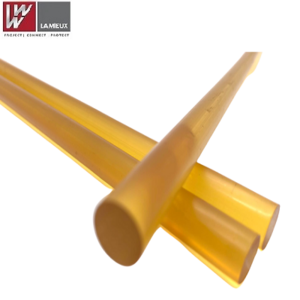

Color:

-

Black

-

Certificate:

-

ROHS, UL94V0

-

Samples:

-

Accept

-

Packing:

-

Water proof Bag

-

MOQ:

-

1 KG

-

Delivery Time:

-

3-5 Working Days

-

Storage:

-

At least 24 months

Quick Details

-

CAS No.:

-

63428-84-2

-

Place of Origin:

-

France

-

Brand Name:

-

BOSTIK

-

Model Number:

-

THERMELT 867 Black HV

-

Type:

-

Hot Melt Adhesives

-

Application:

-

Low pressure molding

-

Raw Material:

-

PA(Polyamide)

-

Features:

-

Water Resistance

-

Color:

-

Black

-

Certificate:

-

ROHS, UL94V0

-

Samples:

-

Accept

-

Packing:

-

Water proof Bag

-

MOQ:

-

1 KG

-

Delivery Time:

-

3-5 Working Days

-

Storage:

-

At least 24 months

Products Features

|

1. Limit temperatures for use

|

-50/+155 [°C]

|

|

2. Application temperature

|

210/230 [°C]

|

|

3. Softening point

|

175-190 [°C]

|

|

4. Brookfield viscosity

|

10-14, At 220 [°C], Adjustable

|

|

5.Yield strength

|

7.8 [Mpa]

|

|

6. Elongation at break

|

450 [%]

|

|

7. Shore hardness(instant)

|

Shore D 32

|

|

8. Glass transition temperature

|

-35 [°C]

|

|

9.Moisture absorption (immersed 14 days)

|

2.8 [%]

|

|

10. UL 94 flammability test

|

V0

|

|

Electrical properties

|

|

|

1. Transversal resistivity (500V)

|

10^11 [Ω.cm]

|

|

2. Dielectric rigidity (23°C)

|

19 [kV/mm]

|

|

3. Relative permitivity (23°C)

|

None

|

|

Thermal properties

|

|

|

HDT B [°C]

|

-

|

|

Vicat A120 [°C]

|

57 [°C]

|

|

Thermal conductivity @23°C

|

~0.2 [W/m.°K]

|

|

Thermal conductivity @180°C

|

~0.6 [W/m.°K]

|

|

α coefficient of linear expansion

|

200-300 [ppm/°K]

|

|

Product Name

|

Operating Range

|

Application Temperature

|

Shore Hardness ( ISO 868 )

|

Softening Point ( ASTMD3461 )

|

|

Thermelt 861

|

-40°C to 125°C

|

190 ~ 210°C

|

38D

|

160°C±5°C

|

|

Thermelt 867

|

-40°C to 150°C

|

200 ~ 220°C

|

45D

|

183°C±5°C

|

|

Thermelt 866

|

-25°C to 115°C

|

180 ~ 210°C

|

30D

|

155°C±5°C

|

|

Thermelt 817 R

|

-15°C to 125°C

|

180 ~ 210°C

|

49D

|

170°C±5°C

|

|

Thermelt 868

|

-40°C to 150°C

|

190 ~ 210°C

|

39D

|

160°C±5°C

|

|

Thermelt 858

|

-40°C to 150°C

|

210 ~ 230°C

|

49D

|

180°C±5°C

|

|

Thermelt 865

|

-55°C to 120°C

|

190 ~ 210°C

|

31D

|

157°C±5°C

|

|

Thermelt 892

|

-20°C to 140°C

|

200 ~ 230°C

|

53D

|

173°C±5°C

|

|

Thermelt 195

|

-20°C to 150°C

|

210 ~ 230°C

|

56D

|

200°C±5°C

|

|

Thermelt 861 HV

|

-40°C to 125°C

|

210 ~ 230°C

|

22D

|

160°C±5°C

|

|

Thermelt 867 HV

|

-40°C to 150°C

|

210 ~ 230°C

|

32D

|

182°C±5°C

|

Contact us

Hot Searches