- Product Details

- {{item.text}}

Quick Details

-

control way:

-

full automatic system

-

production capacity:

-

10000 tires per day

-

operation person:

-

6-8 workers

-

type:

-

tyre vulcanizing machine

-

final product:

-

8-22" tire

-

raw material:

-

reclaimed rubber

-

flooring area:

-

500 SQ.M

Quick Details

-

Place of Origin:

-

Shandong, China

-

sales market:

-

20 more than countries

-

Hs code:

-

84778000

-

control way:

-

full automatic system

-

production capacity:

-

10000 tires per day

-

operation person:

-

6-8 workers

-

type:

-

tyre vulcanizing machine

-

final product:

-

8-22" tire

-

raw material:

-

reclaimed rubber

-

flooring area:

-

500 SQ.M

Bicycle Tire Vulcanizing Press / Motorcycle Tyre Molding Machine

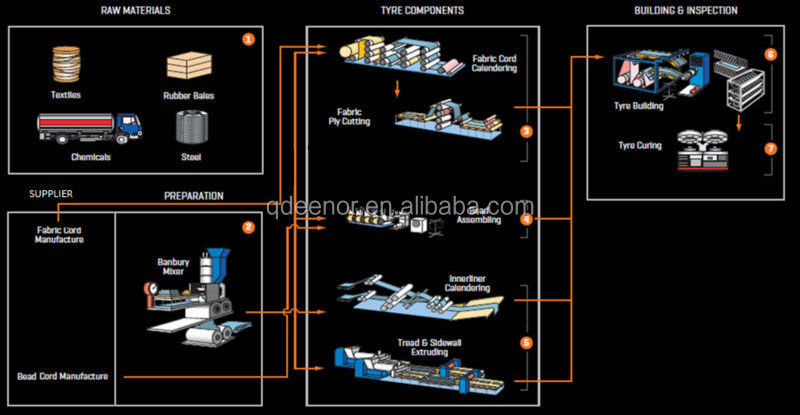

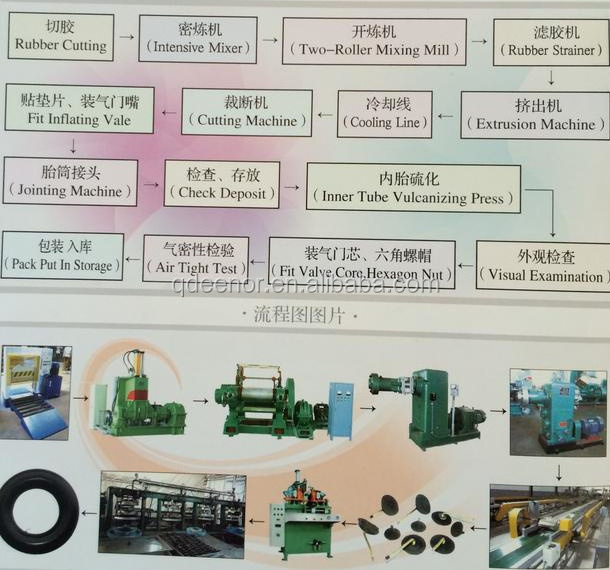

1-the whole production process:

2-the detailed parameters of each machines:

|

Motorcycle tyre production line including the following all machines. |

|||||

|

Model |

Name of equipment |

Model |

QTY |

Notes |

|

|

Milling phase |

|||||

|

1 |

Single blade cutter |

660-1 |

|

Width of blade660mm |

|

|

2 |

Banbury mixer |

X(S)M-35/30 |

1 |

Hydraulic rollover unloading |

|

|

3 |

Mixing mill |

XK-450 |

1 |

|

|

|

4 |

Rubber sheet cooling machine |

XPA-600 |

1 |

Working length 10 meters |

|

|

Calendering phase |

|||||

|

1 |

Four roller calender |

XY4-1400 |

1 |

Include front,back device |

|

|

2 |

Mixing mill |

XK-450 |

1 |

|

|

|

Molding phase |

|||||

|

1 |

Mixing mill |

XK-450 |

1 |

|

|

|

2 |

Mixing mill |

XK-400 |

1 |

|

|

|

3 |

Rubber extruder |

XJ-150 |

1 |

|

|

|

4 |

Shutter car |

10 layers |

10 |

2000×900×60 |

|

|

5 |

Vertical cutting machine |

LC-1500 |

1 |

|

|

|

6 |

Bead ring unit |

|

1 |

|

|

|

7 |

STB former |

|

2 |

|

|

|

Vulcanizing phase |

|||||

|

Unit 1 |

Four layers hydraulic vulcanizing machine |

80T |

6 |

Inclued 2 sets process for tyre |

|

|

2 |

Splicer |

|

1 |

|

|

|

3 |

Tyre shell perforating machine |

|

2 |

|

|

|

4 |

Tyre shell heading press |

|

2 |

|

|

|

5 |

Extruder |

XJ-115 |

1 |

|

|

|

6 |

Mixing mill |

XK-400 |

1 |

|

|

|

7 |

Tire shell machine |

|

3 |

|

|

|

8 |

Tyre air setting machine |

|

3 |

|

|

|

9 |

Mold |

According customer’s quantity,patterns and other requirements |

|||

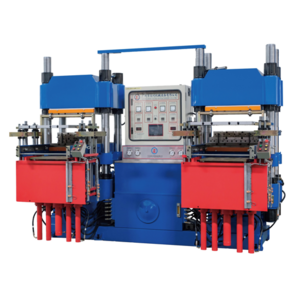

TYRE VULCANIZING MACHINE:

INNER TUBE VULCANIZING MACHINE:

TYRE INNER TUBE MOLDS:

FINAL PRODUCTS

INNER TUBE EXTRUDING MACHINE:

TYRE MOLDS:

FINAL PRODUCTS

THE PRODUCTION LINE WAS PASS"BV" AUTHENTICATION:

Why choose us?

We are ready to give them a turnkey solution, by designing the line according to their space, designing all electrical Installation, water installation, civil foundation, training their people and proving that they will get the targets for production according to the design.

The cost of the machinery they are paying is one off but the correct production design and machine configuration in order to get the production targets is the most important point. Even if somebody got the cheapest machine quotation, at the end of the day, what is count are the production quantity, quality and the durability of the machines so to cover the investment in the correct time.

A satisfies customer can bring you ten more customers but one disappointed customer can send away one hundred customers. Reputation in the market is the most important factor for keeping business healthy and in growing line.