Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

HYPET

-

Voltage:

-

380V 50Hz 3Phase or customized

-

Weight:

-

15000 KG

-

Keywords:

-

Automatic Solid PVC WPC Foam Board extrusion machines

-

Final product:

-

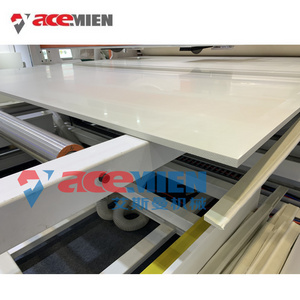

PVC Foam Board

-

Raw material:

-

PVC Composite powder

-

Profile range:

-

5-20mm thickness

-

Width:

-

1220mm

-

Extruder type:

-

Conic twin screw extruder

-

Control system:

-

PLC with touch screen

-

Motor/Inverter:

-

Siemens/ABB/China top brand

-

Certification:

-

ISO9001, CE

-

Engineer installation service:

-

Yes

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

28:1

-

Screw Speed (rpm):

-

39 rpm

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

HYPET

-

Voltage:

-

380V 50Hz 3Phase or customized

-

Weight:

-

15000 KG

-

Keywords:

-

Automatic Solid PVC WPC Foam Board extrusion machines

-

Final product:

-

PVC Foam Board

-

Raw material:

-

PVC Composite powder

-

Profile range:

-

5-20mm thickness

-

Width:

-

1220mm

-

Extruder type:

-

Conic twin screw extruder

-

Control system:

-

PLC with touch screen

-

Motor/Inverter:

-

Siemens/ABB/China top brand

-

Certification:

-

ISO9001, CE

-

Engineer installation service:

-

Yes

Product Description

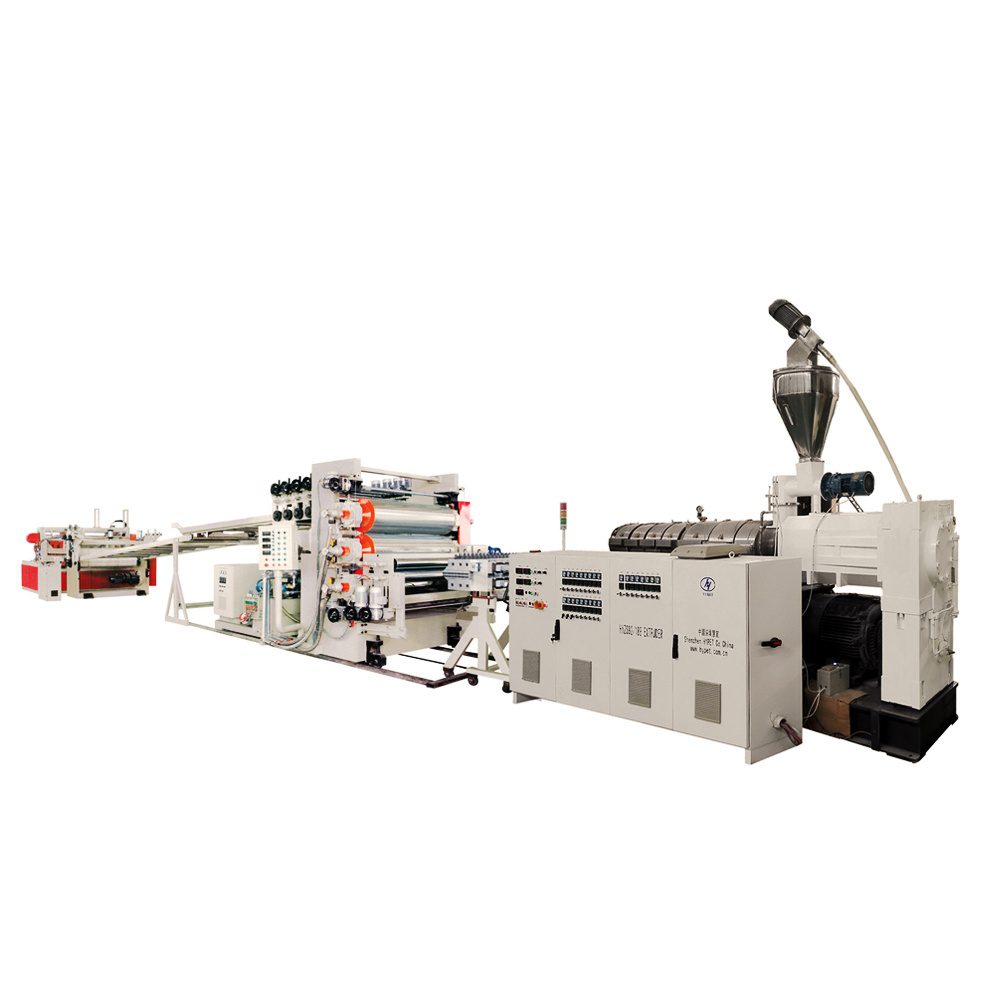

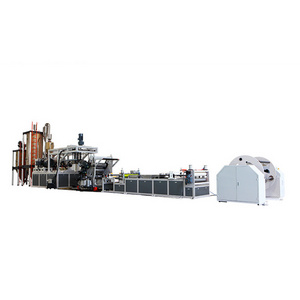

PVC FOAM BOARD PRODUCTION LINE

1. New generation gear box to put bearings near to the screws not in the far back;

2. With ZS80/173 extruder, production is 20% higher than using ZS80/156.

3. HYPET Extruder + die device to make the product more hard & bright;

4. HYPET barrel in two parts bi-matal, and totally hard alloy ensure more than 3 years; (less than 75 CaCo3)

5. Electric cabinet can be separated; Electrical cabinet and mechanical detachable, as Cincinnati structure;

6. HYPET made own PLC control program to meet intelligent requirement;

7. Electromagnetic induction heater to save energy.Adopt Germany technology, it can achieve the highest output of China equipment;

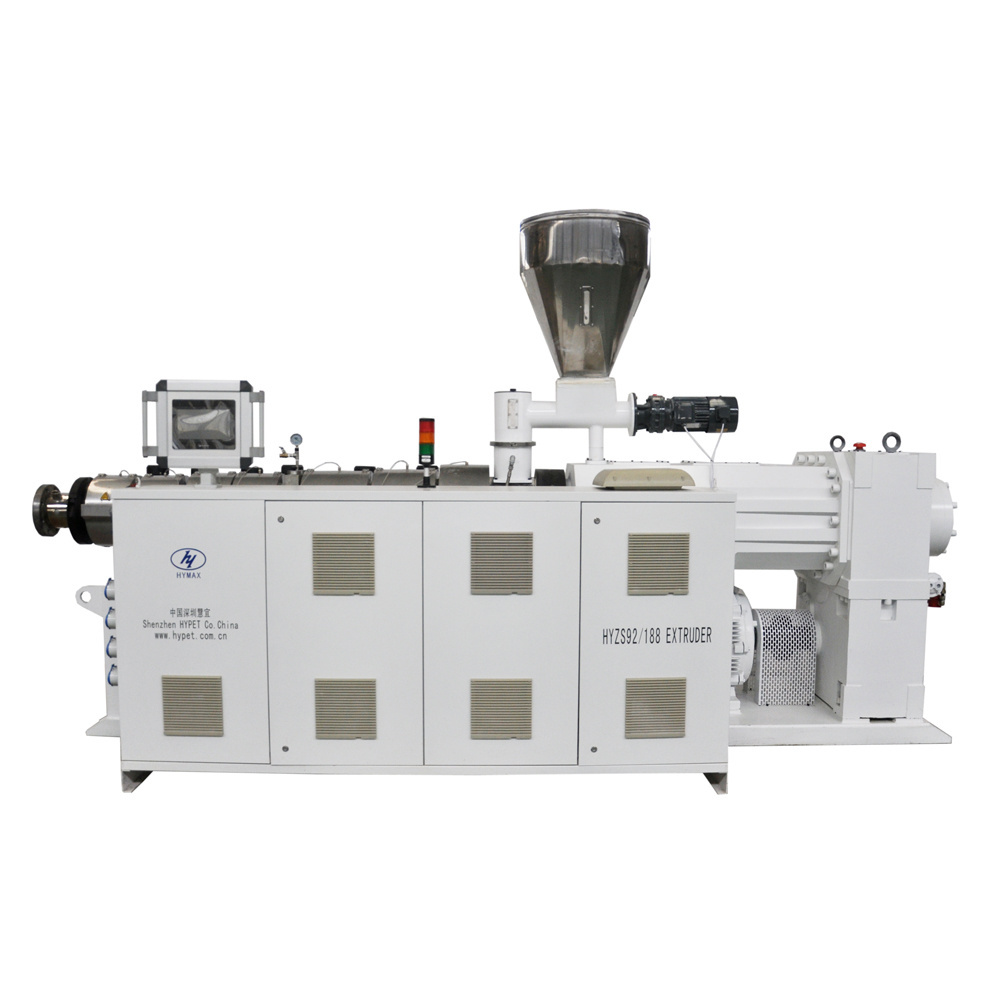

Conic Twin Screw Extruders

H

igh output /

H

igh torque /

H

igh quality

Self owned gear box patent

Self designed screw

Dual cooling system

Anti blocking feeder

Super size touch screen

Energy saving heaters

Low noisy blower

Top brand inverter

Strong motor

|

Twin conic screw extruder series

|

|

|

|

|

|

|

|

|

|

|||||||||

|

Item

|

35/80

|

45/100

|

51/110

|

55/120

|

65/132

|

|

80/156

|

80/173

|

92/188

|

|||||||||

|

Main motor

|

7.5

|

15

|

18.5

|

30

|

37

|

45

|

55

|

75

|

110

|

|||||||||

|

Output

|

75

|

120

|

140

|

250

|

350

|

450

|

550

|

650

|

950

|

|||||||||

|

Vacuum pump

|

1.1kw

|

1.5kw

|

1.5kw

|

1.5kw

|

2.2kw

|

2.2kw

|

3kw

|

3kw

|

4kw

|

|||||||||

|

Price USD

|

11500

|

13500

|

14500

|

16300

|

17500

|

18500

|

27500

|

3300

|

43500

|

|||||||||

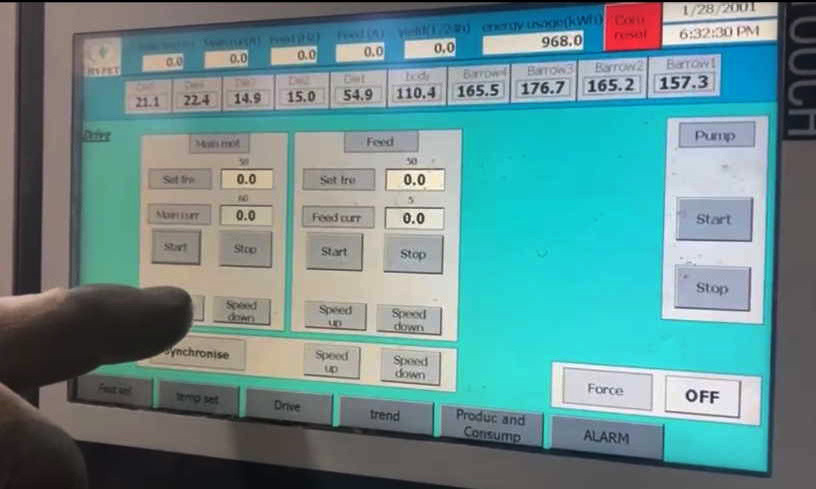

Operating Screen

Super size operating screen to keep operation easily and well

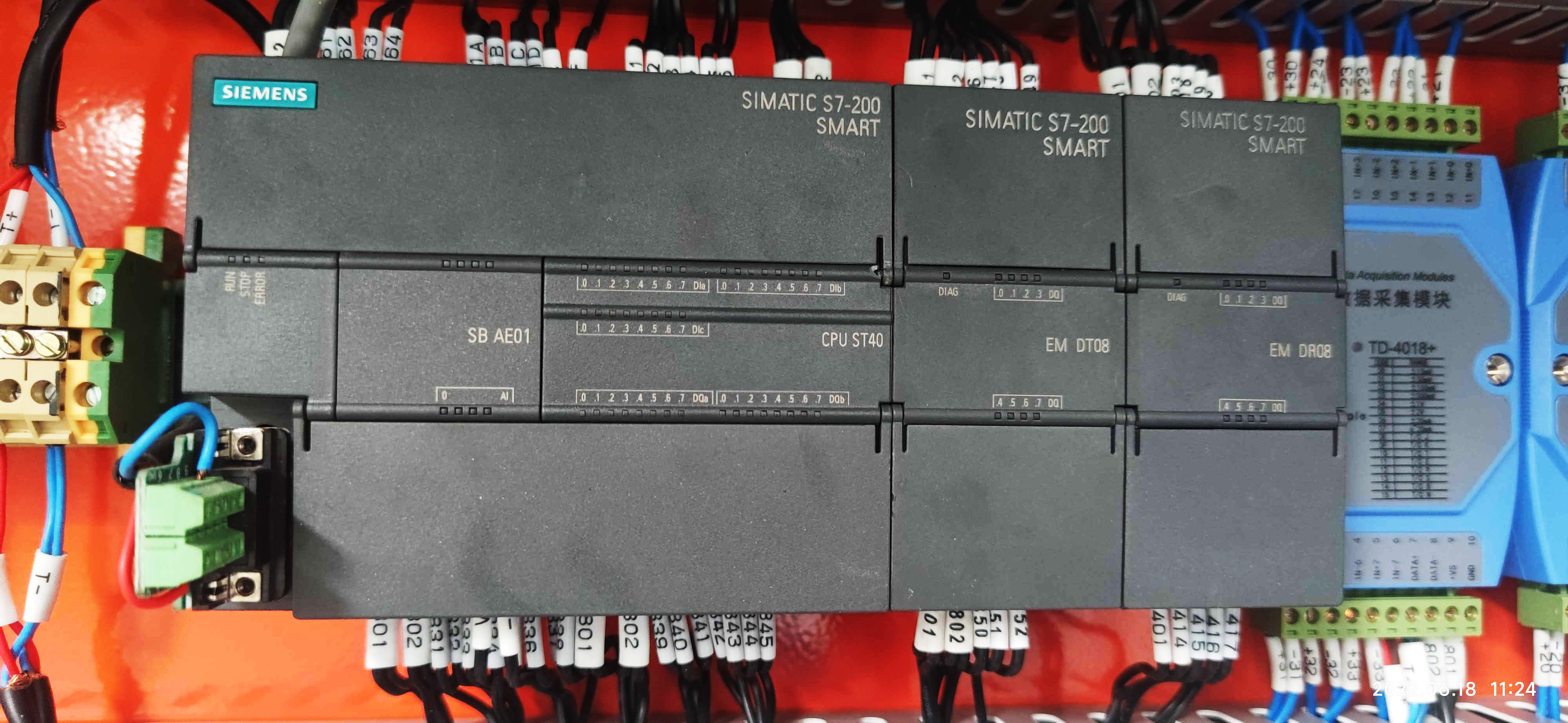

Control system

Top brand Siemens PLC control sytem as operating heart

Heaters & blowers

Energy saving type heaters and low noisy blowers

Feeder

Special anti blocking design

Frequency inverter

ABB or Heavy type Delta

Gear box

Own patent with two cooling

MOLDS

The pressure class and standard will be made according to the requirement.

Materials of construction, alloy steel with flow path hard chrome plated.

The flow path are milled and are highly polished.

Better material and design for longer time running and better surface.

Calibrator

Type:Separated 5 group

Size of calibrating plate:1,500 x 500 x 100mm

Material of calibrating plate:45# steel, Surface hard chrome plated and polished, the surface roughness of 0.8µm

No. 1 & 2 calibrating plate:3 in/ 3 out cooling

No. 3 &4 calibrating plate:2 in/ 2 out cooling

Vertical distance adjustment:Cylinder control

Vertical adjustment range:0~80 mm

Front and rear adjustment:Cylinder

Conveyor

Length:6m

Roller size:1500mm x Φ70

Material of roller:Stainless steel

Structure of roller:Drawer type

Drive unit:Without power, passive type.

Edge cutting machine:Blade type, 2 blades

Haul OFF

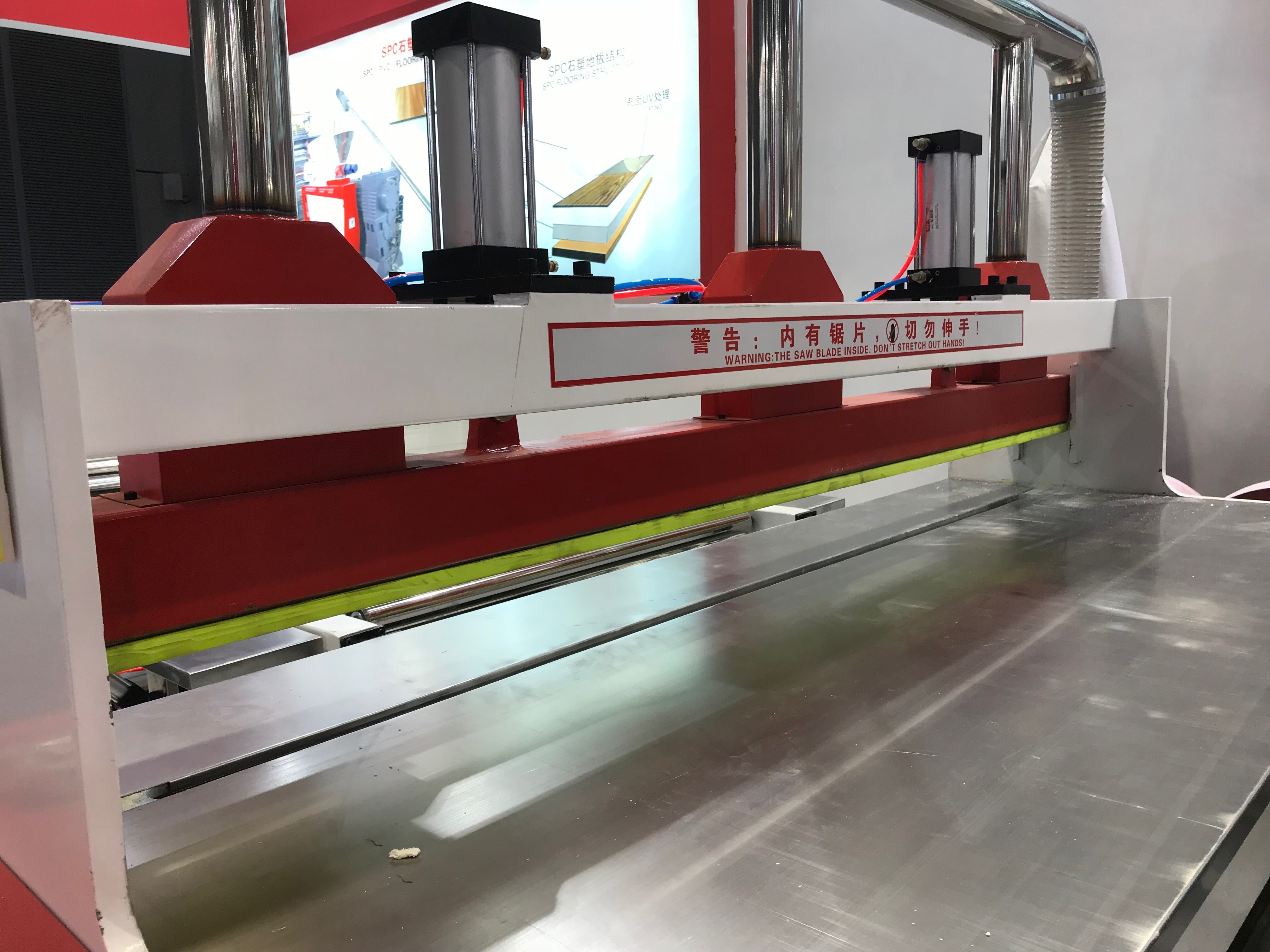

VERTICAL CUTTER

Max. Cutting width:1220mm

Min. Cutting width:900mm

Cutting thickness:3~25mm

Cutting plate type:Right angle

Material of blade:High quality alloy

Motor:2.2 kW x 2 sets

HORIZONTAL

CUTTER

Max. Cutting width:1500mm

Moving control:Gears and linear guide

Vertical moving power:0.55 kW

Horizontal moving power:3 kW

Inverter:DELTA/ABB

Dust absorbing device:5.5 kW

Control method:PLC

STACKER

Cooperative brands

Auxiliary machine for option

Puliverizer

Recycled scraps into powder

Mixer

Mixing PVC, filler, chemical agent

Crusher

Recycle the bad final product into scrap

Precise cutter

Cutting the door edge

Polishing machine

Brushing the door surface

Hotstamping machine

Door surface pattern film

Series Lines & Data

|

No.

|

Profile range

|

Extruders

|

Main Motor

|

Output

|

|

1

|

1220

|

ZS80/156

|

55

|

350

|

|

2

|

1220

|

ZS80/173

|

75

|

450

|

|

3

|

1220

|

PS110/28

|

90

|

550

|

|

Profile & Sheet production ine series

|

|

|

|

|

|

|

||||||

|

Final product

|

Width

|

Output

|

Extruder

|

Motor

|

Calibrator

|

Price

|

||||||

|

PVC ceiling & decorating panel

|

300

|

160

|

ZS55/120

|

30kw

|

3m

|

38250

|

||||||

|

PVC ceiling & decorating panel

|

300

|

250

|

ZS65/132

|

37kw

|

4m

|

41660

|

||||||

|

PVC ceiling & decorating panel

|

600

|

350

|

ZS65/132

|

45kw

|

3.5m

|

53470

|

||||||

|

PVC ceiling & decorating panel

|

600

|

450

|

ZS80/156

|

55kw

|

4.5m

|

65050

|

||||||

|

PVC door panel

|

1200

|

550

|

ZS80/173

|

75kw

|

8m

|

69000

|

||||||

|

PVC-WPC decoration panel

|

300

|

250

|

ZS65/132

|

37kw

|

6m

|

39430

|

||||||

|

PVC-WPC decoration panel

|

600

|

350

|

ZS65/132

|

45kw

|

6m

|

49980

|

||||||

|

PVC-WPC decoration panel

|

600

|

450

|

ZS80/156

|

55kw

|

6m

|

60980

|

||||||

|

Plastic marble sheet

|

1220

|

450

|

ZS80/156

|

55kw

|

3 rollers

|

100660

|

||||||

|

PVC foam board

|

1220

|

350

|

ZS80/156

|

55kw

|

separated

|

99700

|

||||||

|

PVC foam board

|

1220

|

450

|

ZS80/173

|

75kw

|

separated

|

105200

|

||||||

|

SPC floor

|

1220

|

650

|

ZS92/188

|

110kw

|

5rollers

|

123000

|

||||||

Recommend Products

Hot Searches