- Product Details

- {{item.text}}

Quick Details

Quick Details

-

Place of Origin:

-

Shanghai, China

-

DIESEL ENGINE:

-

KUBOTA/DEUTZ/HONDA

Atlas Copco XAS88 with complete set of new TEX32PS Pneumatic breakers

ATLAS COPCO

XAS38 XAS48 XAHS38 XAS58 XAS68 XATS68 XAS78 XAS88

|

Compressor Data |

XAS88KD |

|

Free Air Delivery @ Normal Working Pressure |

(5m³/min ) 178cfm |

|

Normal Working Pressure |

7 bar 102psi |

|

Minimum / Maximum Unloading Pressure |

4 / 8.5 bar |

|

Compression Stages |

1 |

|

Compressor Oil Capacity |

7.7L |

|

Approximate Air Outlet Temperature |

90°C (Standard) |

|

Typical oil content of compressed air |

<5 mg/m³ |

|

Fuel Tank Capacity |

60L |

|

Outlet Valve Configuration |

3 x 3/4” G, 1 x 1.5” G |

|

Nominal working condition |

Inlet pressure 1bar,Humidity0%,Temp20 °C |

|

Sound Pressure Level (ISO2125) |

70dB(A) +/- 3 |

|

Maximum Ambient Temperature at sea level |

45 °C |

|

Maximum Altitude |

5000 m |

|

Minimum Starting Temperature |

-10 °C / -20 °C (with assist) |

|

Diesel Engine Data |

Kubota |

|

Horsepower Developed @ Rated Speed |

32.5kW |

|

Cylinders |

4 |

|

Cooling System |

Oil |

|

Engine Coolant Capacity |

-- |

|

Engine Oil Capacity |

5.5 Liter |

|

Unloaded Speed / Maximum Loaded Speed |

1850 / 2750RPM |

|

Fuel Consumption @ 0% Load / 100% Load |

3.6 / 7 kg/h |

|

Dimensions |

Standard Towing Speed20 km/h |

|

Length |

2290 mm ( within towbar ) |

|

Width |

1350mm |

|

Height |

1400mm |

|

Weight ( filled with oil & coolant , Initial fuel ) |

750 kg |

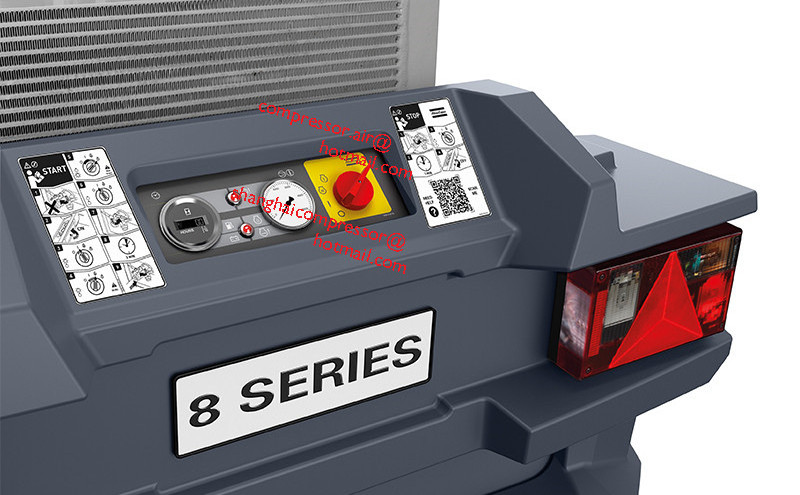

THE AMAZING NEW 8 SERIES

What do you tow?

The new 8 Series compressor range from Atlas Copco is the result of over a decade of continuous development. For the first time, it’s possible to transport behind a normal passenger car, with no special driving license, a compressor that can produce up to 5m3/min of air, with a full size fuel tank, after-cooler and generator all incorporated into a compact and lightweight package. This is all made possible by the latest development in our pioneering air element design, meaning we can produce a compressor up to 150kg lighter than comparable models. However, we understand that this means nothing without efficiency. Efficiency can mean many things, such as: reduced service time, fuel consumption or increased utilization. The 8 Series ticks all the boxes when it comes to delivering outstanding performance in all of these categories.

Lastly, depending on your application you might ask about robustness, durability, ruggedness or toughness – we have one simple word for all of the above – The HardHat?. This legendary canopy was born in 2005 and the 8 Series features the latest, toughest design. The amazing new 8 Series from Atlas Copco, it’s all about the numbers, it’s all about changing the game and we have one clear challenge to you – what do you tow?

The 8 series is the latest product launched in-line with the Forward-Thinking philosophy of the Portable Energy division

YOU. NOT US

We are focused on your needs and delivering products that add value to you.

ENGINEERED. NOT ASSEMBLED

We have global research and development capabilities coupled with Industry leading investments in innovation.

SOLUTIONS. NOT COMPROMISE

We are proud to offer you the widest portfolio along with the maximum number of customizable options.

EFFICIENT. NOT WASTEFUL

We focus on how to improve your environment and minimize the impact on the planet.

UPTIME. NOT DOWNTIME

We work to your schedule. We are here to make sure you ‘run’ when you need to run.

LEADER. NOT FOLLOWER

We will always bring you something new; to help us both stay ahead of the game. It’s about looking ahead and staying ahead, in order to help our customers do the same.

002

OPTIONS

• Adjustable towbar with brakes

• Adjustable towbar without brakes

• Fixed towbar with brakes

• Fixed towbar without brakes

• DoT approved undercarriage

• Support mounted

• Support leg

• Jockey wheel

• Road signalization + wheel chocks

• Towing eye (DIN, NATO, AC, BNA, ITA ,GB , Ball coupling)

• Loose ball coupling

• Special colours

• Cold start

• Toolbox

• Aftercooler + water separator

• Aftercooler + water separator + reheater

• Aftercoooler by-pass

• Additional fuel filter

• Safety cartridge

• Lubricator

• Non-return valve

• Tilt protection

• Air filter vacuum system

• Hose reel

• 4th O/L valve (simple attachment)

• DPF

ISO STANDARDS

Atlas Copco’s fully implemented Quality Management and Environmental Management systems in the design and manufacturing of these units fulfill the requirements of ISO 9001 and ISO 14001 & OHSAS 18001. The range has also been given the certificate tested according to ISO 1217:2009-annex D.

8 STEP SIMPLE SERVICE

Atlas Copco Portable Air compressors

XAS70 XAS90 XAHS70 XAS110 XAS125 XATS130 XAS150 XAS185

Protecting your investment ? HardHat ™

XA(T,H)S 70-90 KD7/70-185 DD7

67-190 cu.ft/min, 32-89 l/s, 1.9-5.3 m 3 /min at 102-175 psig, 7-12 bar(e)

HardHat ™ Built for tough times

Around the world, construction and demolition site personnel wear a hard hat for protection. Now another important member of the team comes with its own safety kit, the latest HardHat™ compressor range from Atlas Copco. Protected by an impact resistant canopy, the nine single-axle HardHat™ models combine great looks and class leading performance with the best damage and corrosion resistance in the business. It is not just protection that is on offer. The one-piece HardHat™ canopy lifts to provide unrivalled service access, a key to reducing costs and minimizing downtime. Maximum protection, great looks and easy service access. Typical forward thinking from Atlas Copco.

The range

The HardHat™ range is built around a single axle Series 7 oil injected rotary screw compressor module. The XAS 70 KD7, XAS 90 KD7 are powered by a choice of Kubota D905 or D1105 three-cylinder engines. The XAHS 70 DD7, XAS 90 DD7, XAS 110 DD7, XA(T)S 130 DD7, XAS 150 DD7 and XAS 185 DD7 are Deutz 2011 two- or three-cylinder engine powered. All models will provide a reliable source of compressed air to drive pneumatic tools. These can include chipping and jackhammers, nut runners, grinders and rammers. High free air delivery applications, such as sandblasting, are also covered. As with all Atlas Copco compressors, a wide range of options is available.

Cost of Ownership

A HardHat™ canopy is tough, really tough. It is designed to be highly impact resistant so it can shrug off dents and fractures. In a tough working environment, this really pays off. Where even the best-protected steel canopy compressors are going to get bashed and bettered, a HardHat™ will keep its good looks longer. No dents, no scratches and corrosion. No time and money consuming repair and repaint jobs. When lower ownership costs count, HardHat™ delivers.

Built and tested to ISO 9001 quality assurance standards

All Atlas Copco equipment is manufactured in accordance with ISO 9001 quality assurance regulations. Every compressor is produced and tested to exacting standards. For optimum performance, in the most demanding conditions, you can count on Atlas Copco.

Atlas Copco :

the world leader in portable air compressors

Atlas Copco manufactures one in three compressors sold throughout the World. Produced in the World’s largest dedicated compressor manufacturing plant, our advanced research and development and proven products ensure we offer the best solution for all your compressed air needs.

Heavy-duty filter

All models are fitted with a single, high performance two-stage air intake filter with service indicator as standard. Proven to prevent dust and dirt entering the engine and the compressor, the filter combines a long service interval with high efficiency.

Low operational cost, high fuel autonomy

Atlas Copco has unrivalled experience in optimizing portable compressor efficiency. All models are fitted with a stepless, fully automatic regulator. This constantly varies the engine speed according to air demand for reduced power and fuel consumption. Looking for a compressor to run long shifts with no need to refuel? Choose a HardHat™.

High efficiency and longevity

Matching an efficient engine and precision-engineered Atlas Copco compressor element guarantees high efficiency, reduced wear and an extended service life.

Designed for the environment

All HardHat™ compressors meet current European and US legal requirements relating to the working environment and regulations concerning safety, exhaust emissions and noise. Kubota D905, D1105 and Deutz 2011 engines fully comply with COM III and TIER II exhaust emission regulations. All models comply with the outdoor noise directive 2000/14/EC Stage II. Atlas Copco has fully implemented its Environmental Management System into the design and manufacturing process of the machines, fulfilling the requirements of ISO 14001.

Options

Aftercooler

All models can be specified with a compressed air after-cooler and water separator. For maximum efficiency, the unit is installed on the cool side of the compressor. For additional liquid and particle removal, the after-cooler can also be specified with additional PD and QD filters.

Lubricator

All 102 psi models are available with a 0.26 US gal lubricator. The flow of oil is easily adjusted to suit the application, an integral indicator clearly showing the level of lubricant remaining.

Customer colors

Pigment is added to the polyethylene used to form the HardHat™ canopy during manufacture. This process ensures the canopy color cannot discolor and scratches are less easy to see. Customers wishing to select an alternative finish to Atlas Copco yellow can choose from a wide range of colors. From pitch black to the brightest white, there is a color to suit most corporate schemes.

Technical data

Dimensions

Protect your investment......and your peace of mind

Atlas Copco carefully monitors the maintenance needs of all its compressors. Service intervals are carefully assessed to ensure optimum performance is maintained and operating costs reduced. Proper maintenance will ensure your compressor runs as efficiently and economically as possible. A lack of maintenance can result in expensive down-time with a subsequent loss of production or poor performance. Avoid risks and protect the asset value of your compressor by choosing one of the unique service options provided by Atlas Copco.

Our service options are flexible. Depending on your requirements, we can supply service kits or spare parts for in-house maintenance or factory service and maintenance packages tailored to user demands.

Genuine Parts

Atlas Copco makes no compromise on the quality of replacement parts: only genuine parts provide the longevity and reliability you demand. Selected high quality Atlas Copco compressor and engine oils are also available. These meet the stringent quality specifications required to enable your unit run smoothly, shift after shift.

Service agreements

For complete peace of mind, Atlas Copco has a range of service agreements to suit your needs. Maintenance budgets are clear and simple, with prices fixed in advance. Operational costs come down and efficiency goes up. You choose the service options and the time period to suit your needs.

Commitment

Atlas Copco employs two thousand factory trained service technicians in over 150 countries worldwide. Should a problem ever occur, access to their expertise is only a telephone call away. With years of experience and ongoing investment, we are the only major compressor manufacturer providing a full 3 year factory supported warranty.

XAS46 XAS56 XAS66 XAS76 XAS65

Atlas Copco Portable air compressors

XAS 46-76

43 to 68 l/s (91 to 145 cu.ft/min) - 7 bar (102 psig)

Series 6

A completely new concept in portable air compressors

Series 6 - XAS46, XAS56, XAS66, XAS76 - is an innovative range of oil injected, rotary screw compressors. These single axle compressors are powered by a new Deutz diesel engine (2 or 3 cylinders) to provide reliable compressed air for pneumatic tools such as chipping hammers, jackhammers, nut runners, grinding tools, and rammers - or for sandblasting. An optional generator provides added power for fusion welding, light poles, heating of cabins, instrumentation and electric power tools.

With our advanced research and development, the world’s largest dedicated compressor manufacturing plant, and proven applications around the world, Atlas Copco is the complete answer to all your compressed air needs.

You’ll find Atlas Copco representatives nearby who are ready to help you. Our extensive global service and dealer network provides local customer support around the world for sales, training and service.

The features you ‘ve always wanted

For the Series 6, Atlas Copco involved end users and sales companies in the design from the very beginning. This attention to your needs resulted in the development of many new features, including a new compressor element, a new diesel engine, a unique canopy and a modular concept that allows you to add many options to suit your needs.

Meets legal safety and environmental requirements

The Series 6 compressors meet current and pending European Community legal requirements for the working environment; and regulations for safety, exhaust emissions, and noise.

Built and tested to ISO 9001 quality assurance standards

Atlas Copco’s stringent manufacturing standards - which follow the ISO 9001 regulations for quality assurance - produce compressors that are made and tested to perform in the most demand-ing conditions.

Atlas Copco - the world leader in portable air compressors

Atlas Copco supplies one out of every three portable air compressors in the world. This remarkable sales record is the result of years of technological leadership in compressed air. We strive to fulfill your highest expectations in quality, performance, reliability and service.

The low decibel rating makes the Series 6 perfect for quiet operation near hospitals and schools, in residential areas, and even at night

Series 6

Principal data