- Product Details

- {{item.text}}

Quick Details

-

Max. Spindle Speed (r.p.m):

-

1600 r.p.m

-

Width of bed (mm):

-

400 mm

-

Spindle Motor Power(kW):

-

5.5

-

Max. Turned Length (mm):

-

1500

-

Travel (X Axis)(mm):

-

240 mm

-

Travel (Z Axis)(mm):

-

1050 mm

-

Positioning Accuracy (mm):

-

0.01

-

Place of Origin:

-

Shandong, China

-

Dimension(L*W*H):

-

2500*1500*1650

-

Model Number:

-

CK6140

-

Voltage:

-

Customer's Requirement

-

Weight (KG):

-

1800

-

Product name:

-

ck6140 CNC Lathe

-

Machine Type:

-

Horizontal CNC Lathe

-

Function:

-

Machining Metal Lathe

-

Usage:

-

Turning Milling Tapping Drilling Functions

-

Max. Swing Diameter (mm):

-

400

Quick Details

-

Type:

-

Horizontal

-

Max. Length of Workpiece (mm):

-

850

-

Year:

-

2020

-

Max. Spindle Speed (r.p.m):

-

1600 r.p.m

-

Width of bed (mm):

-

400 mm

-

Spindle Motor Power(kW):

-

5.5

-

Max. Turned Length (mm):

-

1500

-

Travel (X Axis)(mm):

-

240 mm

-

Travel (Z Axis)(mm):

-

1050 mm

-

Positioning Accuracy (mm):

-

0.01

-

Place of Origin:

-

Shandong, China

-

Dimension(L*W*H):

-

2500*1500*1650

-

Model Number:

-

CK6140

-

Voltage:

-

Customer's Requirement

-

Weight (KG):

-

1800

-

Product name:

-

ck6140 CNC Lathe

-

Machine Type:

-

Horizontal CNC Lathe

-

Function:

-

Machining Metal Lathe

-

Usage:

-

Turning Milling Tapping Drilling Functions

-

Max. Swing Diameter (mm):

-

400

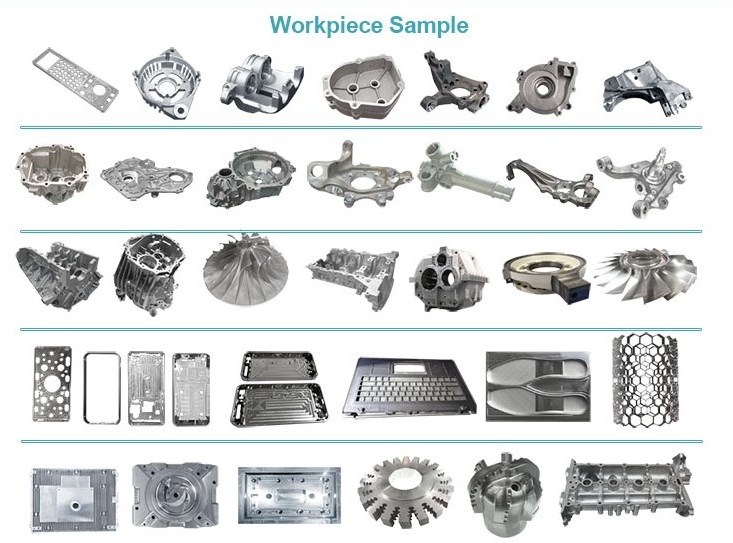

Products Description

CK6140 price list automatic chuck cnc turning lathe horizontal machine is a high-precision, high-efficiency automated machine tools, the whole machine with integrated protection structure, beautiful appearance. Mainly used for complex shape parts or high precision parts processing, can automatically complete internal and external Round surface, conical cotton, round face, end face, a variety of threads, drilling, hinge, boring and other turning. The machine is tested in strict accordance with the inspection procedure. Each machine adopts laser interferometer to detect X and Z axis positioning accuracy and repeat positioning accuracy to ensure the accuracy and reliability of the machine.

Specifications

|

Machine Model

|

Unit

|

CK6140

|

CK6150

|

|

Swing over bed

|

mm

|

400

|

500

|

|

Swing over cross slide

|

mm

|

210

|

260

|

|

Distance between centers

|

mm

|

750/1000/1500/2000

|

750/1000/1500/2000

|

|

Spindle bore

|

mm

|

52(Optional 80)

|

52(Optional 80)

|

|

Spindle bore taper

|

-

|

MT6

|

MT6

|

|

Spindle nose type

|

-

|

C6

|

C6

|

|

Spindle speed steps

|

-

|

Manual 2 steps

|

Manual 2 steps

|

|

Spindle speed range

|

rpm

|

L:100-500 H:500-1800 (Optional 90-1800 stepless)

|

L:100-500 H:500-1800 (Optional 90-1800 stepless)

|

|

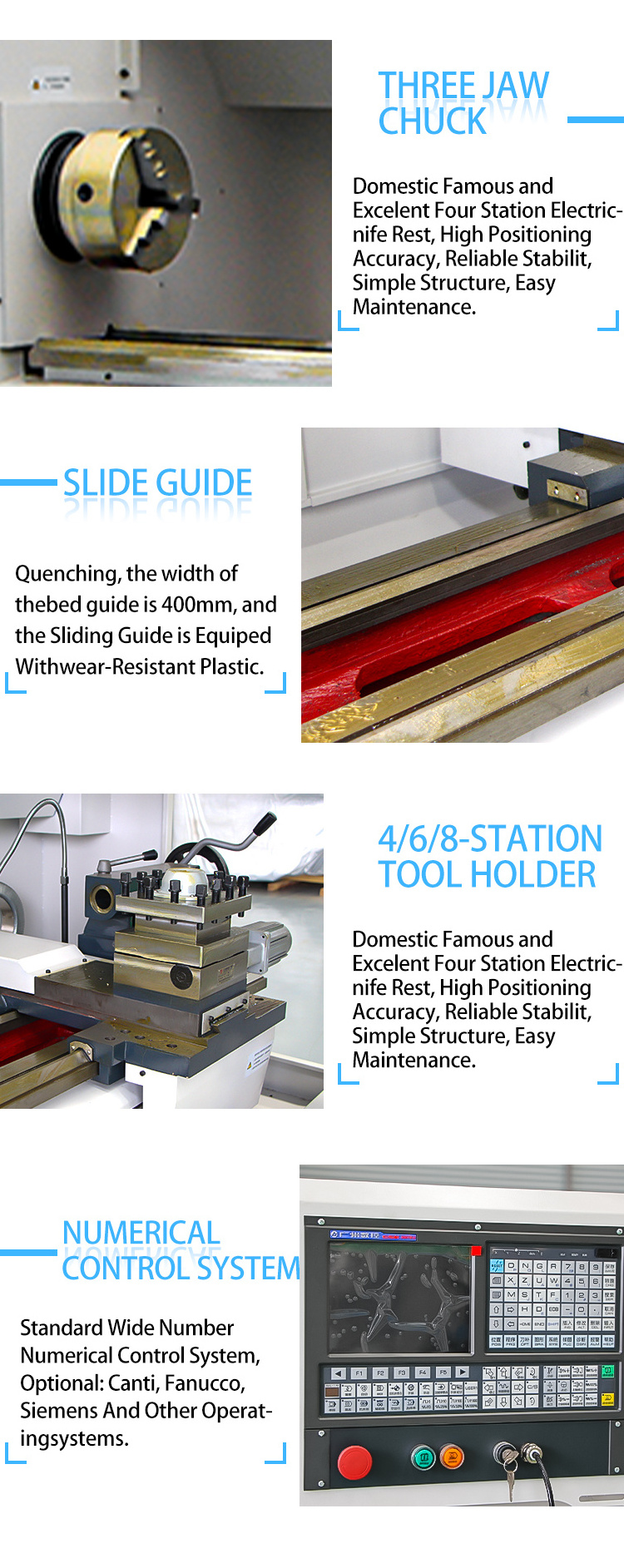

Turret/tool post

|

-

|

Electric 4 position

|

Electric 4 position

|

|

Tool size

|

mm

|

25 x 25

|

25 x 25

|

|

X axis travel

|

mm

|

230

|

280

|

|

Z axis travel

|

mm

|

750/1000/1500/2000

|

750/1000/1500/2000

|

|

X axis rapid traverse

|

mm/min

|

6000

|

6000

|

|

Z axis rapid traverse

|

mm/min

|

8000

|

8000

|

|

Tailstock quill diameter

|

mm

|

65

|

65

|

|

Tailstock quill taper

|

-

|

MT4

|

MT5

|

|

Tailstock quill travel

|

mm

|

130

|

130

|

|

Main spindle motor

|

kw

|

4

|

5.5

|

|

Coolant pump motor

|

kw

|

0.09

|

0.09

|

|

Weight for 750

|

kg

|

1700

|

1800

|

|

Weight for 1000

|

kg

|

1800

|

1900

|

|

Weight for 1500

|

kg

|

1900

|

2000

|

|

Weight for 2000

|

kg

|

2000

|

2100

|

|

Dimension for 750

|

mm

|

2200x1650x1700

|

2200x1700x1750

|

|

Dimension for 1000

|

mm

|

2500x1650x1700

|

2500x1700x1750

|

|

Dimension for 1500

|

mm

|

3000x1650x1700

|

3000x1700x1750

|

|

Dimension for 2000

|

mm

|

|

3500x1700x1750

|

Details Display

Recommend Products

Hot Searches