- Product Details

- {{item.text}}

Quick Details

-

Warranty:

-

6 month

-

Blade Width:

-

25-250mm

-

Place of Origin:

-

Zhuzhou Hunan

-

Brand Name:

-

LW / LAIWEI

-

Model Number:

-

solid carbide saw blade

-

Grade:

-

K10/K20/K30

-

Application:

-

Cutting Wood / Metal cutting

-

Product Name:

-

TCT Circular Saw Blade

-

Usage:

-

Cutting Hard Metal

-

Material:

-

tungsten carbide + Co

-

Advantage:

-

High Efficiency

-

Cutting material:

-

Composite Materials

-

Package:

-

Inner Box + Outer Carton

-

Feature:

-

High Speed

-

Quality:

-

High Top

Quick Details

-

Blade Length:

-

25-250mm

-

Finishing:

-

uncoated

-

Size:

-

25-250mm, Customized Size

-

Warranty:

-

6 month

-

Blade Width:

-

25-250mm

-

Place of Origin:

-

Zhuzhou Hunan

-

Brand Name:

-

LW / LAIWEI

-

Model Number:

-

solid carbide saw blade

-

Grade:

-

K10/K20/K30

-

Application:

-

Cutting Wood / Metal cutting

-

Product Name:

-

TCT Circular Saw Blade

-

Usage:

-

Cutting Hard Metal

-

Material:

-

tungsten carbide + Co

-

Advantage:

-

High Efficiency

-

Cutting material:

-

Composite Materials

-

Package:

-

Inner Box + Outer Carton

-

Feature:

-

High Speed

-

Quality:

-

High Top

Product Description

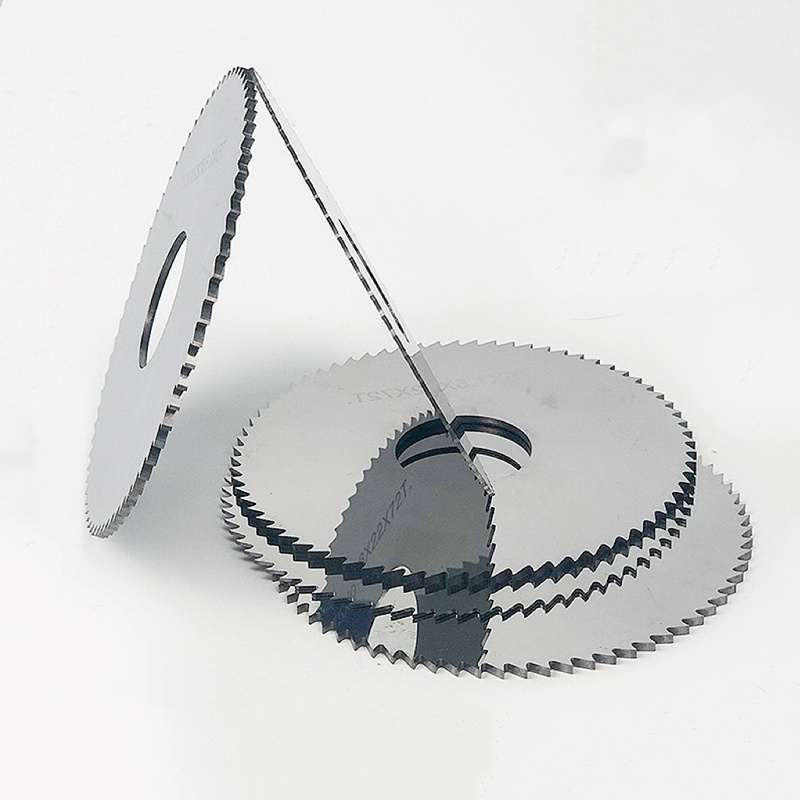

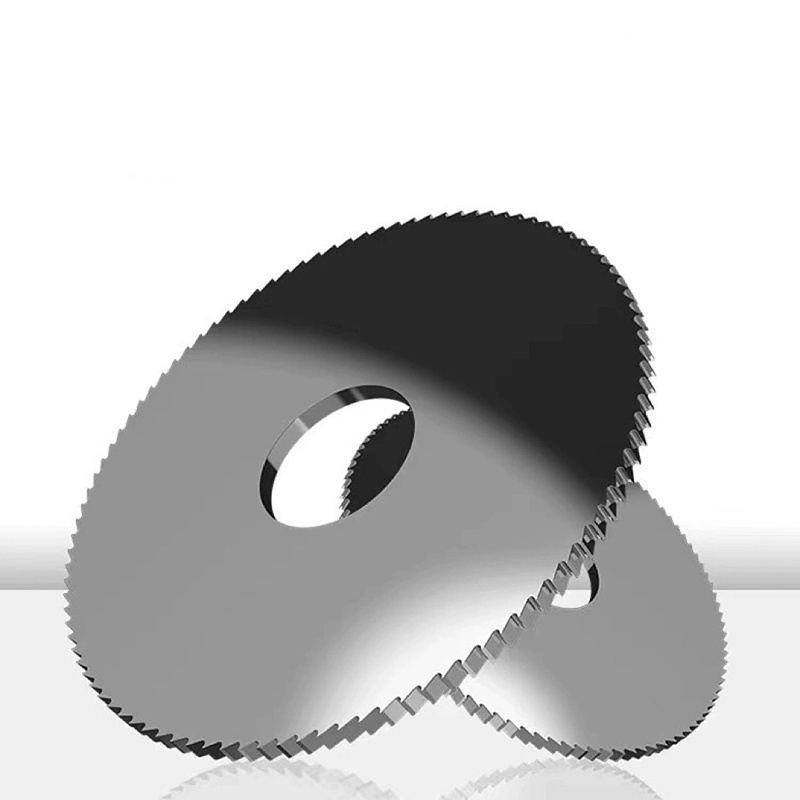

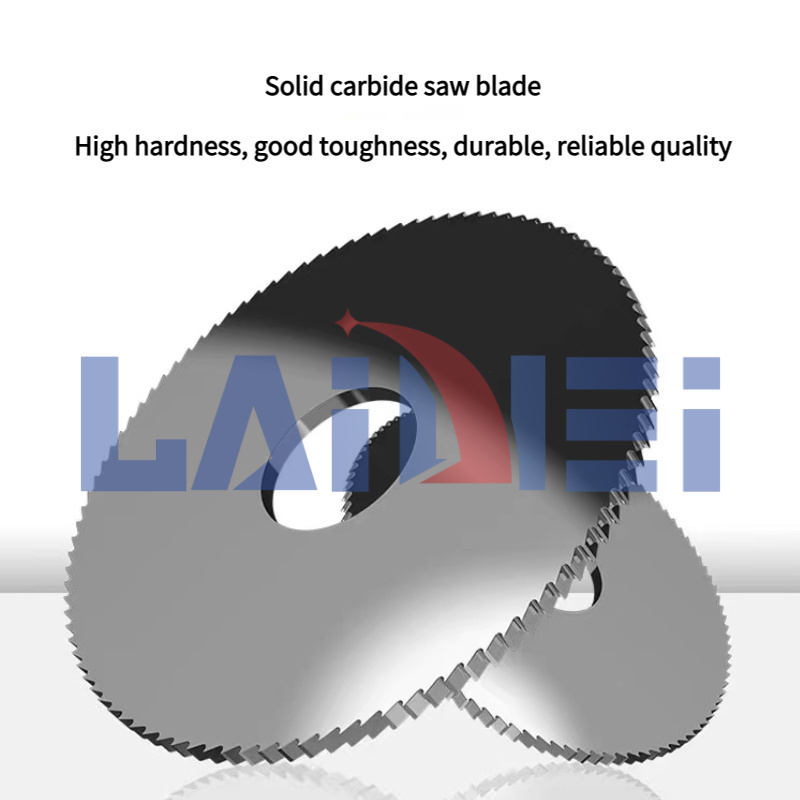

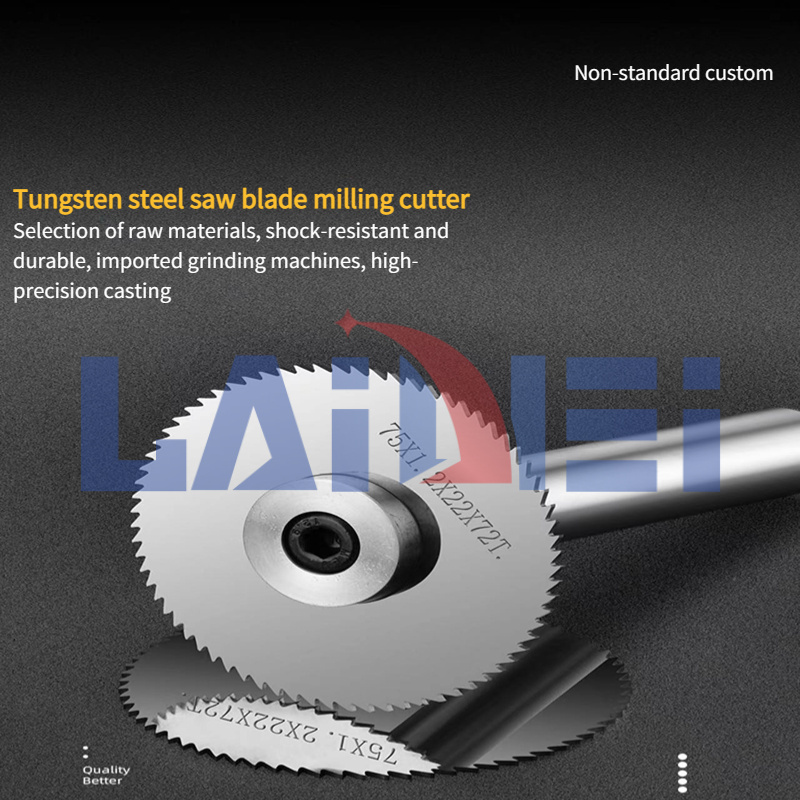

Solid carbide circular saw blades with different sizes and different grades, mainly used for iron, aluminum, copper and other metal materials, and plastic, wood slotting and cutting with its good wear resistance, high strength, high impact and shock resistance ability.

Product Features

1. Long life with supper resistance to heat, wear and abrasion.

2.Good finish:milling line speed high finish better

3.Efficient:high-speed milling processing speed can be greatly improved.

1. Long life with supper resistance to heat, wear and abrasion.

2.Good finish:milling line speed high finish better

3.Efficient:high-speed milling processing speed can be greatly improved.

Advantages

1 High quality, supper sharp + smooth cutting + long working life

2 100% raw material, HIP-Sintered

3 CNC grinding for teeth, with high precision

4 Various grades for different kinds of cutting material

5 Strict quality control, complete test equipments

6 Competitive price

7 Good after sale service

1 High quality, supper sharp + smooth cutting + long working life

2 100% raw material, HIP-Sintered

3 CNC grinding for teeth, with high precision

4 Various grades for different kinds of cutting material

5 Strict quality control, complete test equipments

6 Competitive price

7 Good after sale service

ensure good performance and to reduce the huge amount of friction. Laser cut steel plate to remain flat and accurate for years of continuous use.

TIPS: Micro grain tungsten carbide tips are used to achieve the correct cutting quality and long life characteristic.

BRAZING: Auto tip seat grinding and Auto brazing machines are set up to get right temperature are teeth placement. The good silver

welding material requires brazing at lower temperature to avoid dangerous results when being used.

SHARPENING: We carefully research the individual bevel tooth design and tooth combination for each blade according to their use.

Auto sharpening phase each angle and make precise to ensure smooth cutting face and effort-saving

Specification

|

OD

|

|

Thickness

|

|

ID

|

|

Number of teeth

|

||||||

|

Basic size

|

Tolerance

|

Basic size

|

Tolerance

|

Basic size

|

Tolerance

|

|

||||||

|

12

|

±0.090

|

0.1-10

|

±0.012

|

5/6

|

+0.0120

|

12/18/24/30/36/40

|

||||||

|

16

|

±0.090

|

0.1-10

|

±0.012

|

5/6

|

+0.0120

|

12/18/24/30/36/40/50

|

||||||

|

20

|

±0.105

|

0.1-10

|

±0.012

|

6/8

|

+0.0120

|

18/24/30/36/40/50/60/72/80

|

||||||

|

25

|

±0.105

|

0.1-10

|

±0.012

|

6/8

|

+0.0150

|

18/24/30/36/40/50/60/72/80

|

||||||

|

32

|

±0.105

|

0.1-10

|

±0.012

|

8/10/12.7/13

|

+0.0150~

+0.0180

|

18/24/30/36/40/50/60/72/80

|

||||||

|

40

|

±0.105

|

0.15-10

|

±0.012

|

8/10/12.7/13

|

+0.0150~

+0.0180

|

30/36/40/50/60/72/80/90

|

||||||

|

45

|

±0.105

|

0.2-10

|

±0.012

|

12.7/13/16

|

+0.0180

|

36/40/50/60/72/80/90/100

|

||||||

|

50

|

±0.105

|

0.2-10

|

±0.012

|

12.7/13/16

|

+0.0180

|

40/50/60/72/80/90/100/120

|

||||||

|

60

|

±0.105

|

0.2-10

|

±0.012

|

12.7/13/16/22/25.4

|

+0.0180

|

40/50/60/72/80/90/100/120

|

||||||

|

63

|

±0.105

|

0.3-10

|

±0.012

|

12.7/13/16/22/25.4

|

+0.0180

|

40/50/60/72/80/90/100/120

|

||||||

|

70

|

±0.105

|

0.4-10

|

±0.012

|

12.7/16/22/25.4/27

|

+0.0210

|

40/50/60/72/80/90/100/120

|

||||||

|

75

|

±0.105

|

0.4-10

|

±0.012

|

16/22/25.4/27

|

+0.0210

|

40/50/60/72/80/90/100/120

|

||||||

|

80

|

±0.105

|

0.5-10

|

±0.012

|

22/25.4/27

|

+0.0210

|

50/60/72/80/90/100/120/150

|

||||||

|

100

|

±0.105

|

0.8-10

|

±0.012

|

22/25.4/27

|

+0.0210

|

50/60/72/80/90/100/120/150

|

||||||

|

125

|

±0.105

|

1.2-10

|

±0.012

|

22/25.4/27/32

|

+0.0210~

+0.0250

|

50/60/72/80/90/100/120/150

|

||||||

|

150

|

±0.105

|

1.4-10

|

±0.012

|

25.4/27/32

|

+0.0210~

+0.0250

|

50/60/72/80/90/100/120/150

|

||||||

|

180

|

±0.105

|

1.6-10

|

±0.012

|

25.4/27/32

|

+0.0210~

+0.0250

|

50/60/72/80/90/100/120/150

|

||||||

|

200

|

±0.105

|

2.0-10

|

±0.012

|

25.4/27/32/40

|

+0.0210~

+0.0250

|

50/60/72/80/90/100/120/150/180

|

||||||

|

1. Special requirements for some small outer diameters: the thinnest thickness can be 0.10. 2. If there is a special requirement

for high precision, the thickness tolerance can also be ±0.003. 3. Special outer diameters, thicknesses, inner diameters, and number of teeth can be customized. |

|

|

|

|

|

|

||||||

|

item

|

value

|

|

Warranty

|

6 month

|

|

Blade Thickness

|

0.014in, 0.032in, 0.05in, 0.02in, 0.3-3mm

|

|

Blade Width

|

25-250mm

|

|

Arbor Size

|

20/22.23

|

|

Teeth per Inch

|

0.42

|

|

Teeths

|

63/70/80/120/150

|

|

Blade Length

|

25-250mm

|

|

Blade Diameter

|

25-250mm

|

|

Edge Height

|

0.315in(8mm), 0.472in(12mm)

|

|

Process Type

|

High Frequency Welded, stainless steel / steel

|

|

Customized support

|

OEM, ODM

|

|

Place of Origin

|

Zhuzhou Hunan

|

|

Brand Name

|

LW / LAIWEI

|

|

Model Number

|

solid carbide saw blade

|

|

Finishing

|

uncoated

|

|

Size

|

25-250mm

|

|

Grade

|

K10/K20/K30

|

|

Application

|

Cutting Wood / Metal cutting

|

|

Product Name

|

TCT Circular Saw Blade

|

|

Usage

|

Cutting Hard Metal

|

|

Material

|

tungsten carbide + Co

|

|

Advantage

|

High Efficiency

|

|

Cutting material

|

Composite Materials

|

|

Package

|

Inner Box + Outer Carton

|

|

Size

|

Customized Size

|

|

Feature

|

High Speed

|

|

Quality

|

High Top

|

Hot Searches