Q1,

what certifications or qualifications does your company have?

A1, our company's certificates include CE, ISO, ROHS, product patent certificates, etc.

Q2. What is the accuracy of the product processed on the blueprint?

A2. Different devices have different accuracies, generally between 0.05 and 0.1 millimeters.

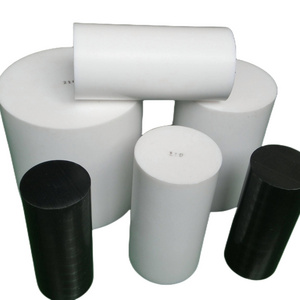

Q3. What process do you have to handle accessories?

A3. According to different products, different processes are used, such as mechanical processing, extrusion, injection molding,

molding, and so on.

Q4, what is your processing equipment?

A4, injection molding machine, extruder, molding machine, CNC machining center, CNC lathe, milling machine, engraving machine.

Q5, can you pack the product according to the requirements after it is completed?

A5, it's okay.

Q6, how long will the parts be delivered?

A6, we can quickly complete orders, but delivery time depends on several factors such as manufacturing process, order quantity,

and part complexity. CNC machining parts only takes 3 days, 3D printing parts only takes 2 days, and forming

Manufacturing with fast tools only takes 5 days.

We manufacture parts to high standards, both for projects and customers.

Q7, can injection molded products undergo surface treatment? What is surface treatment?

A7, it's okay. Surface treatment: painting, screen printing, electroplating, etc.

Q8, can I request samples?

A8, provide samples according to actual situation.

Q9. I want to protect my IP. Is my design safe?

A9, we attach great importance to privacy and security, and will happily sign a Non Disclosure Agreement (NDA) according to your

requirements, so that you can rest assured of intellectual property.