- Product Details

- {{item.text}}

Quick Details

-

Power:

-

Customized

-

Weight:

-

250kg

-

Dimension(L*W*H):

-

Customized

-

Name:

-

Tomato paste industrial food sterilizer

-

Heating way:

-

Steam boiler

-

Material:

-

Stainless Steel 304/316L

-

Control system:

-

Automatic

-

Application:

-

Fruit jam,tomato paste

-

Certification:

-

ISO,CE

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Rockaway

-

Voltage:

-

380V/415V/440V

-

Power:

-

Customized

-

Weight:

-

250kg

-

Dimension(L*W*H):

-

Customized

-

Name:

-

Tomato paste industrial food sterilizer

-

Heating way:

-

Steam boiler

-

Material:

-

Stainless Steel 304/316L

-

Control system:

-

Automatic

-

Application:

-

Fruit jam,tomato paste

-

Certification:

-

ISO,CE

Tomato paste industrial food sterilizer

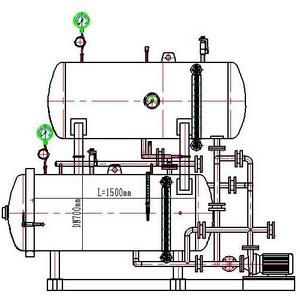

Tube-in-tube sterilizer :

Application:

The food sterilizer is fit for

thick and other high viscous products. The tubular shell heat exchanger unit is designed for sterilizing and cooling of products containing fibers and particles. The sterilization temperature is typically 135~ 140C for 4 seconds holding. We will make temperature holding pipes behind the sterilizer according to your sterilization time for example 3 minutes or 5 minutes.

Quality control:

The unit is pre-assembled and tested before it leaves the factory. The installation on site only requires connection to external service such as product inlet and outlet, water, steam, air and electricity.

Structure:

-SS frame

- Set of tubular heat exchangers with:

Regenerating section

Sterilization section

Hot water section

Cooling section

- Balance tank

- Product pump

- Holding tube

- Hot water pump

- Control panel with:

Siemens PLC controller

Siemens Touch screen

Alarm for high and low temperature

Alarm for high temperature and low flow in hot water section

On/off buttons for pumps

Indicator for and control of pasteurizing temperature

- Set of internal pipes, valves and fittings

The unit is designed for CIP via recirculation over the balance tank and dosing of chemicals automatically.

Parameters:

Temperature process: 5°C→65°C →95°C / 30S→140°C / 4S→25°C

Ice water 1:1 (≤2°C) or Cooling water 1:1(30°C)

|

|

RA-UHT-1.5 |

RA-UHT-3 |

RA-UHT-5 |

|

Production capacity ( L/H ) |

1500 |

3000 |

5000 |

|

Inlet temperature |

25 °C -40 °C |

25 °C -40 °C |

25 °C -40 °C |

|

Holding time(s) |

120-180 |

120-180 |

120-180 |

|

Sterilize temperature |

95 ~ 121 °C |

95 ~ 121 °C |

95 ~ 121 °C |

|

Product outlet temperature |

25 °C -35 °C |

25 °C -35 °C |

25 °C -35 °C |

|

Tower water inlet temperature |

≤30 °C |

≤30 °C |

≤30 °C |

|

Steam pressure |

0.5MPa |

0.5MPa |

0.5MPa |

|

Steam consumption |

~ 150Kg/h |

~ 210Kg/h |

~ 280Kg/H |

|

Compressed air pressure |

0.6MPa |

0.6MPa |

0.6MPa |

|

Compressed air consumption |

50L/H |

50L/H |

60L/H |

|

External dimension ( homogenizer excluded ) |

7000×2000×2000 |

7000×2000×2000 |

7000×2000×2200 |

|

Total weight of machine |

1700kg |

2000Kg |

2200 Kg |