- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

X10

-

SIZE:

-

CUSTOMIZED accepted

-

Product Name:

-

Customized Used Outdoors PVC Pipe Fittings Plastic Injection Mould

-

Material:

-

45#,50#,P20,H13, 718 2738, NAK80,S136

-

Service:

-

ODM/OEM

-

Sample:

-

Free Sample

-

Design software:

-

UG,PROE,CAD

-

Delivery Time:

-

25-30 days

-

Runner:

-

Cold /Hot

-

Mould base:

-

FUTABA,LKM,HASCO,DME

-

Mould Life:

-

200~1 M available

Quick Details

-

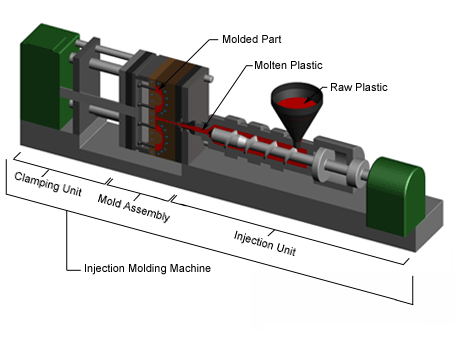

Shaping Mode:

-

Plastic Injection Mould

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

XiangYu

-

Model Number:

-

X10

-

SIZE:

-

CUSTOMIZED accepted

-

Product Name:

-

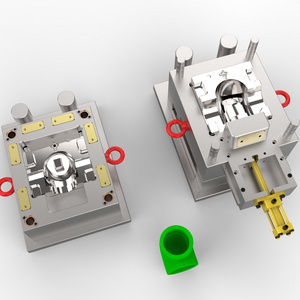

Customized Used Outdoors PVC Pipe Fittings Plastic Injection Mould

-

Material:

-

45#,50#,P20,H13, 718 2738, NAK80,S136

-

Service:

-

ODM/OEM

-

Sample:

-

Free Sample

-

Design software:

-

UG,PROE,CAD

-

Delivery Time:

-

25-30 days

-

Runner:

-

Cold /Hot

-

Mould base:

-

FUTABA,LKM,HASCO,DME

-

Mould Life:

-

200~1 M available

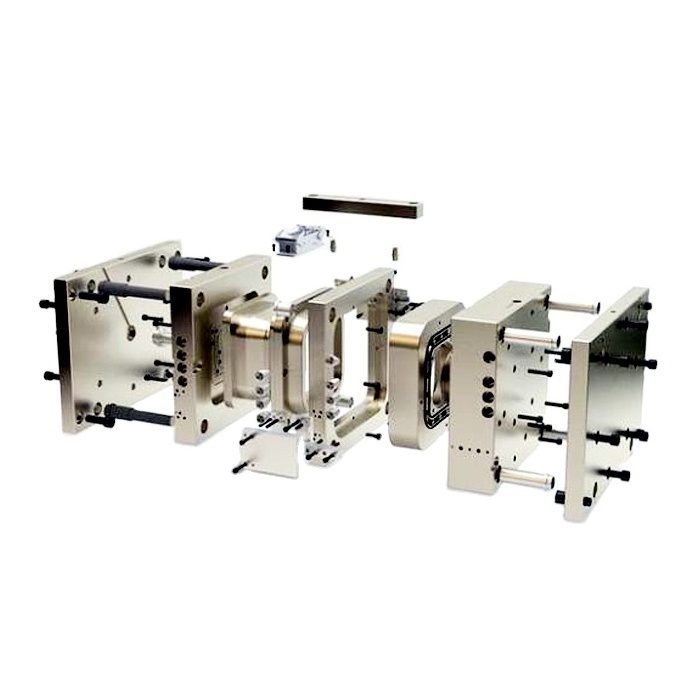

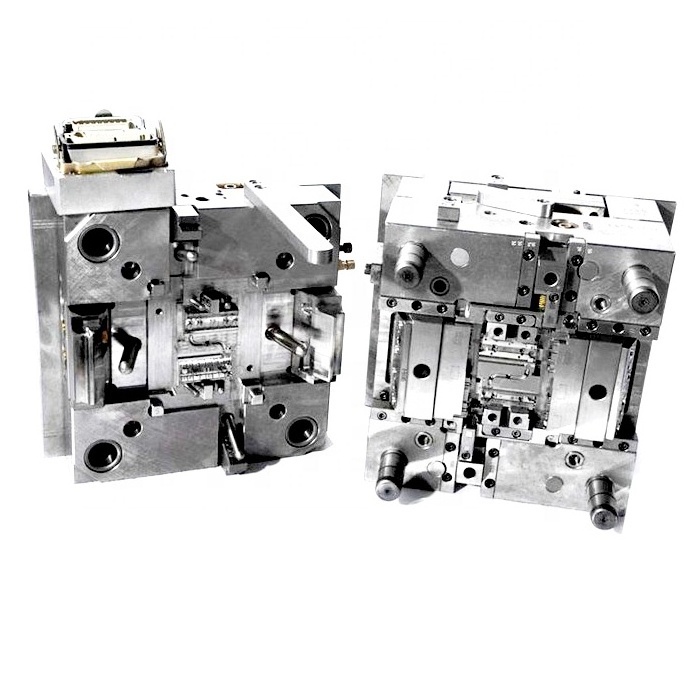

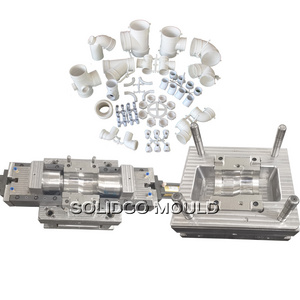

White Customized Used Outdoors PVC Pipe Fittings Plastic Injection Mould

The Reasons you choose us:

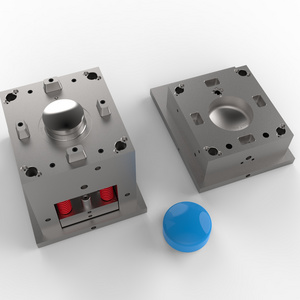

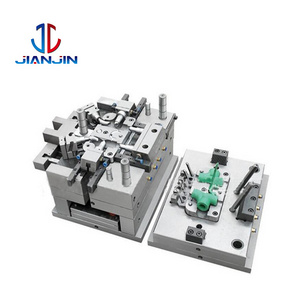

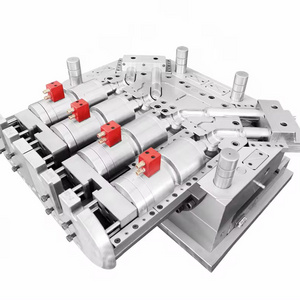

1. We are specialized in automobile plastic injection products and mould manufacture for bumper, dashboard, light,fitness parts,household plastic,cosmetic packing and etc.

2. Professional Controllable Plastic injection process

3. plastic materials, colors, shapes are accepted customed.

|

|

Plastic Mold (Moulds) production process |

Description |

| 1. 3d Design/Samples for quotation | According to 3D drawing or samples for quotation. |

| 2 .Negotiations |

Including the price of moulds, moulds sizes, material for cores & cavities, weight of product, part cost, payment, moulds lifetime, delivery, etc. |

| 3. Purchasing Order | After the customer confirming the mould design and quotation. |

| 4. Making mold(moulds) |

Confirm drawing, start to do DFM,mold flows and mold detail agreed with the customer, start production. |

| 5. Production schedule | Every week we will feedback to the customer a mold progress(picture). |

| 6. sample shoot |

We provide the moulds test samples for confirmation(about 10-15 piece), then, get your signature sample ,mass production. |

| 7. Package | Wooden case for moulds, cartons for parts ,or as your requiretment. |

| 8. Delivery | deliver goods by air or by sea. |