- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

2900*3200*2890

-

Year:

-

2021

-

Power (kW):

-

35 kW

-

Weight (KG):

-

10000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

working layers:

-

1-4 layers

-

colour:

-

all colour

-

voltage:

-

as your local need

-

Power(W):

-

5.5 KW

-

Weight:

-

decided by model, about 28T

-

Keyword:

-

Platen Vulcanizing Press

-

Marketing Type:

-

New Product 2021

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HONGHESHENG

-

Voltage:

-

380V/220V/450V

-

Dimension(L*W*H):

-

2900*3200*2890

-

Year:

-

2021

-

Power (kW):

-

35 kW

-

Weight (KG):

-

10000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

working layers:

-

1-4 layers

-

colour:

-

all colour

-

voltage:

-

as your local need

-

Power(W):

-

5.5 KW

-

Weight:

-

decided by model, about 28T

-

Keyword:

-

Platen Vulcanizing Press

-

Marketing Type:

-

New Product 2021

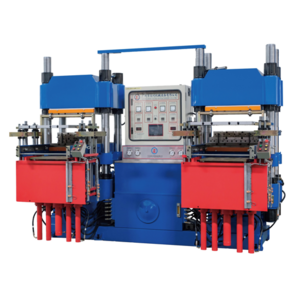

Rubber machine , rubber compression press , rubber plate vulcanizing machine

This machine mainly consists of main machine , hydraulic station , PLC cabinet , IR sensor and etc . It is widely used to vulcanize , heat , and solidify various kinds of rubber molded products .

1.The cylinder ( piston ) adopts the best seals structure , with reasonable design and reliable function. The seals part is good quality YX type

polyurethane seals (not rubber seal ) ,which is oil resistant , aging resistant . The Oil seal is NOK brand from Janpan .

2. Automatic control : automatic mold closing , automatic exhausting , automatic heating and keep stable temperature, automatically timing for vulcanization , automatic alarming , automatic mold opening ,etc

3.The vulcanizing temperature can be set and showed in the digital displan . For example , if you need 250 C , just set250 C in the digital panel .When it reaches your aimed temperature , the temperature will stop to rise and keep stable.Sensor are installed in the heating plate and connect with the temperature indicator in the heating plate . It will show clear the temperature of every heating plate

4.Vulcanizing time can be set in the PLC screen . If you want to heat and vulcanize for 1 minutes , just set it directly . When it reaches 1minutes ,machine will alarm then machine will open the mold automatically

5.frame plate is made of high quality 45 steel . The hardness , wear resistance and abrasive resistance is high improved by quenching and tempering.The pillar will be plated with chrome

6.The top beam and bottom plate form is welded with the good quality Q-235A ductile iron .After welding , it is also processed by the artificial vibration or high temperature aging treatment , to eliminate the internal stress and avoid the deformation

7.plunger is made of LG-P cold hard alloy steel . Surface of it owns high hardness and wear resistant.Depth of chilled layer is 8-15mm , hardness is HRC 60-70 , making the plunger own long life time

8.we will install the IR sensor in both side of press to protect safety of any opeators

9.The hydrualic pupm and valve will be use Yuken Hydraulic pump & valve

For FCL goods, we usually pack machines with stretched film and then load them to the container. to ensure safety, we will fix machine with steel .

For LCL goods, we usually pack machines with standard wood boxes first, and then they will be transported .

1 Guarantee : 2 years ,manufacturer sell, We offer lifetime technical support

2After sales:

1 once problems appear, we will reply in 24 hours. And give solutions

2provide facory layout drawing . Engineers available to service machinery overseas; Send the engineers to debug the machines,Train your workers to use machine.

1. Q: Are you a manufacturer or trading company?

A: We are the manufacturer. We have our own plant,worker and techniques research developing department .

2 .Q: Where is your factory located? How can I visit there?

A: Our factory add is Tieshan industrial Park, Jiaonan, Qingdao, Shandong province, China.

Nearest airport is Qingdao liuting international airport

Kindly send plane information in advance, so that we can pick you up at the airport, and book hotels as you require.

3. Q: What are your hot sale machine?

A: Our rubber and plastic machines are popular in the foriengn market. And main products are tyre recyling plant ,press machine and other machine.

4. Q: How does your factory do regarding quality control?

A: Quality is priority and we have our own quality control department. We win make a strick inspectin before the machines leave the factory.

5 .Q: Are the techncal parameter is fixed?

A: Basically, each model corresponding to the related machine. But we can design different type machine according to the client’s requirement.

6 How to send us your enquiry? Kindly tell me answer

-1 what is your rubber tile size ? 500*500mm?1000*1000mm?

-2tile shape? better send tile picture or drawing?

-3 Leave your cellphong? Skype? whatsApp?viber? so that we can talk efficientl