- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

230-391-5

-

Place of Origin:

-

Shandong

-

Brand Name:

-

Asianry

-

Model Number:

-

110

-

Type:

-

Pu foam

-

Application:

-

Gap Filling

-

Color:

-

Light Yellow

-

packing:

-

15pcs per carton

-

OEM:

-

Avaliable

-

Quality:

-

Guarantee

-

Material:

-

Polyuerthane

-

Shelf life:

-

12 Months

-

Brand:

-

OEM Accpetable

-

Sample:

-

Sample Avaliable

-

Delivery Time:

-

7-15days

Quick Details

-

CAS No.:

-

9009-54-5

-

Other Names:

-

PU foam

-

MF:

-

mixed

-

EINECS No.:

-

230-391-5

-

Place of Origin:

-

Shandong

-

Brand Name:

-

Asianry

-

Model Number:

-

110

-

Type:

-

Pu foam

-

Application:

-

Gap Filling

-

Color:

-

Light Yellow

-

packing:

-

15pcs per carton

-

OEM:

-

Avaliable

-

Quality:

-

Guarantee

-

Material:

-

Polyuerthane

-

Shelf life:

-

12 Months

-

Brand:

-

OEM Accpetable

-

Sample:

-

Sample Avaliable

-

Delivery Time:

-

7-15days

Product Description

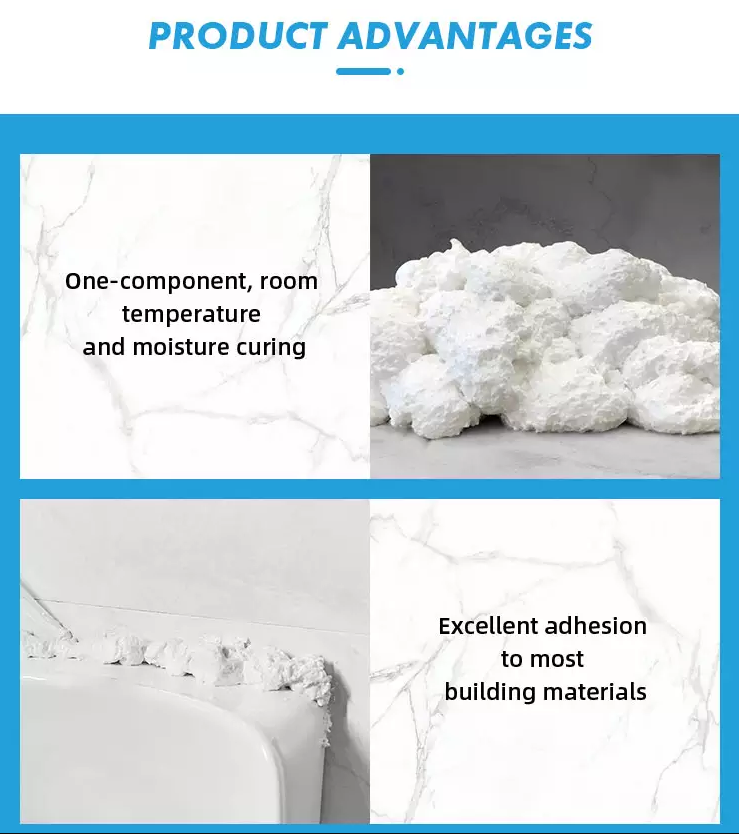

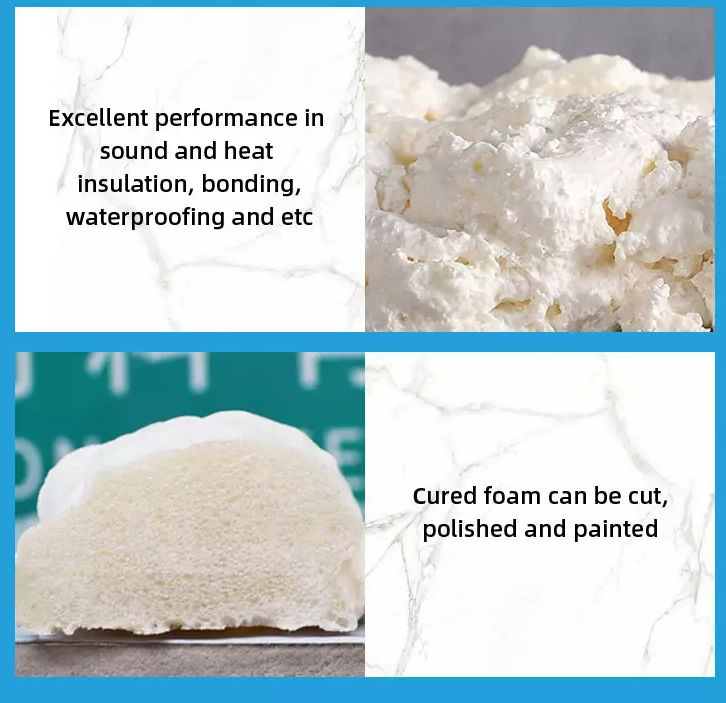

Multipurpose large expansion PU foam sealant is an one-component, self-expanding,multipurpose polyurethane foam. This foam will expand and cure by moisture in the air. It is used for a wide range of building applications. It is very good for filling and sealing with excellent mounting capacities, high thermal and acoustical insulation. Higher expansion rate than normal Pu foam.

ADVANTAGE

1.Can apply around 70 meters ( 30mm*15mm)

2.Most cost effective for each window or door.

3.No shrinkage and cracking after cured.

4.Better adhesion and harder.

CONSTRUCTION GUIDE

1. Shake can vigorously for one minute before use

2. Clean and pre-moisten surface before use

3. Firmly screw can on adapter, and turn the flow adjustment screw anticlockwise

4. Fill vertical joints from the bottom up when half filled enough

5. Foam begins to cure about ten minutes, wait for one hour before doing the next step.

6. Use knife to smooth out cured foam and treat surface with cement paint or silicone.

1.Can apply around 70 meters ( 30mm*15mm)

2.Most cost effective for each window or door.

3.No shrinkage and cracking after cured.

4.Better adhesion and harder.

CONSTRUCTION GUIDE

1. Shake can vigorously for one minute before use

2. Clean and pre-moisten surface before use

3. Firmly screw can on adapter, and turn the flow adjustment screw anticlockwise

4. Fill vertical joints from the bottom up when half filled enough

5. Foam begins to cure about ten minutes, wait for one hour before doing the next step.

6. Use knife to smooth out cured foam and treat surface with cement paint or silicone.

|

As supplied at 25°C and R.H.50 % conditions

|

|

|

|

Base

|

Polyurethane

|

|

|

Consistency

|

Stable Foam

|

|

|

Curing System

|

Moisture-cure

|

|

|

Tack-Free Time(min)

|

7~18

|

|

|

Cutting Time(hour)

|

≥0.7

|

|

|

Yield (L)900g.gw/750ml

|

35~40

|

|

|

Shrink

|

None

|

|

|

Cellular Structure

|

60~65% open cells

|

|

|

Specific Gravity (kg/m³)

|

17-22

|

|

|

Temperature Resistance

|

-40℃~+80℃

|

|

|

Application Temperature Range

|

5℃~35℃

|

|

|

Colour

|

Off white

|

|

|

Fire Class (DIN 4102 )

|

B3

|

|

|

Insulation Factor (Mw/m.k)

|

<34

|

|

|

Compressive Strength (kPa)

|

>100

|

|

|

Tensile Strength (kPa)

|

>30 (10%)

|

|

|

Adhesive Strengh(kPa)

|

>80

|

|

How to use PU foam ?

Product Features

Packing & Delivery

Hot Searches