- Product Details

- {{item.text}}

Quick Details

-

Table Travel (Z) (mm):

-

200 mm

-

Travel (W-axis) (mm):

-

0 mm

-

Marketing Type:

-

New Product 2021

-

Range of Spindle Speed(r.p.m):

-

800 r.p.m

-

Spindle Motor Power(kW):

-

1.8

-

Production Capacity:

-

8 Sets/month

-

Place of Origin:

-

Shaanxi, China

-

Brand Name:

-

Premier Machines

-

Voltage:

-

220V

-

Dimension(L*W*H):

-

1860*1150*2200mm

-

Weight (T):

-

1.2 T

Quick Details

-

Table Size (mm):

-

Other

-

Table Travel (X) (mm):

-

990 mm

-

Table Travel (Y) (mm):

-

40 mm

-

Table Travel (Z) (mm):

-

200 mm

-

Travel (W-axis) (mm):

-

0 mm

-

Marketing Type:

-

New Product 2021

-

Range of Spindle Speed(r.p.m):

-

800 r.p.m

-

Spindle Motor Power(kW):

-

1.8

-

Production Capacity:

-

8 Sets/month

-

Place of Origin:

-

Shaanxi, China

-

Brand Name:

-

Premier Machines

-

Voltage:

-

220V

-

Dimension(L*W*H):

-

1860*1150*2200mm

-

Weight (T):

-

1.2 T

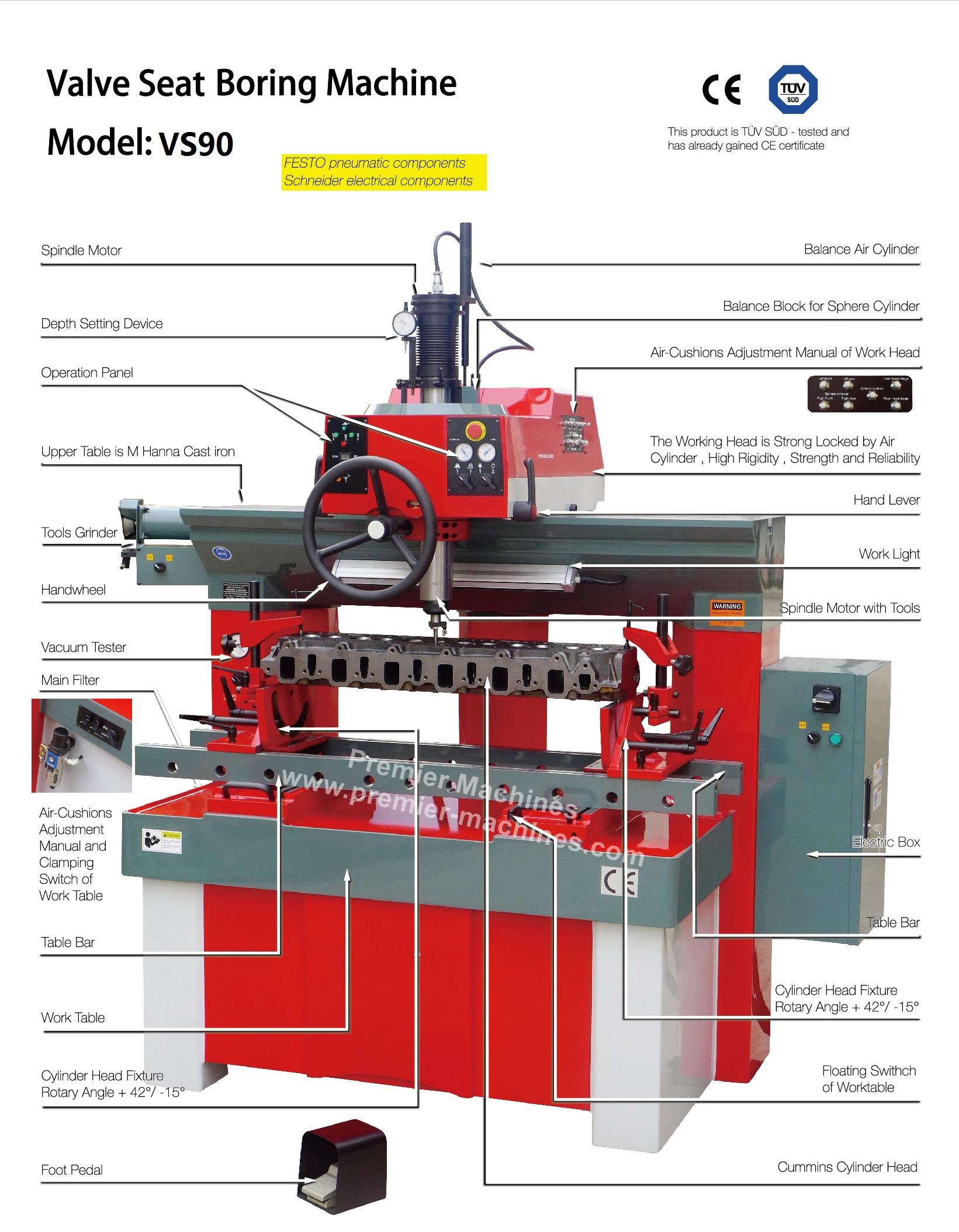

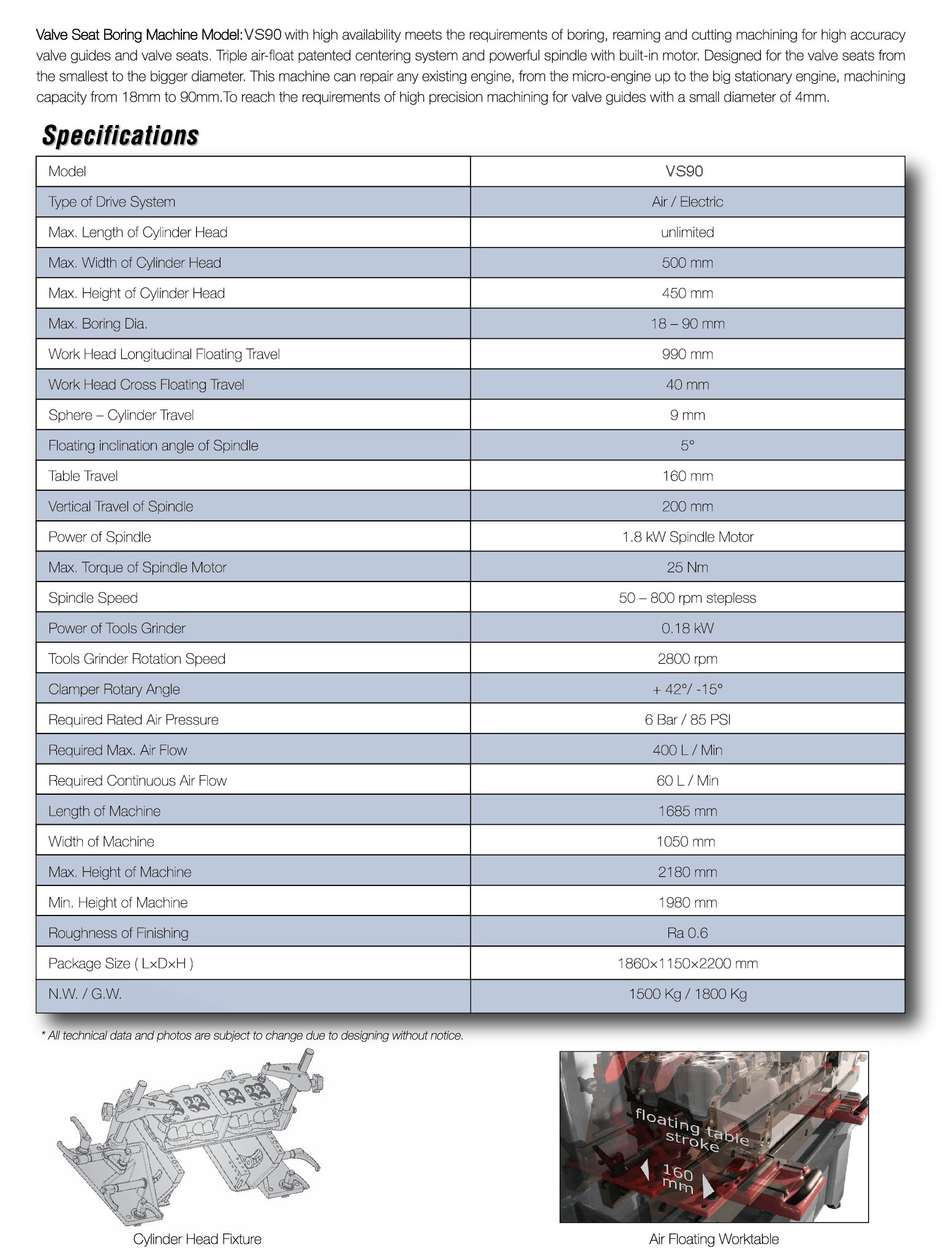

Valve Seat Boring Machine

Model: VS90

2) Machining Capacity: 18 - 90 mm

3) Modernized design of standard machine body to agree with the improved rigidity. Dynamic and static features are optimized by computer to provide the most advanced machining process.

4) Improved lighting system

5) Pneumatic clamping of table bars

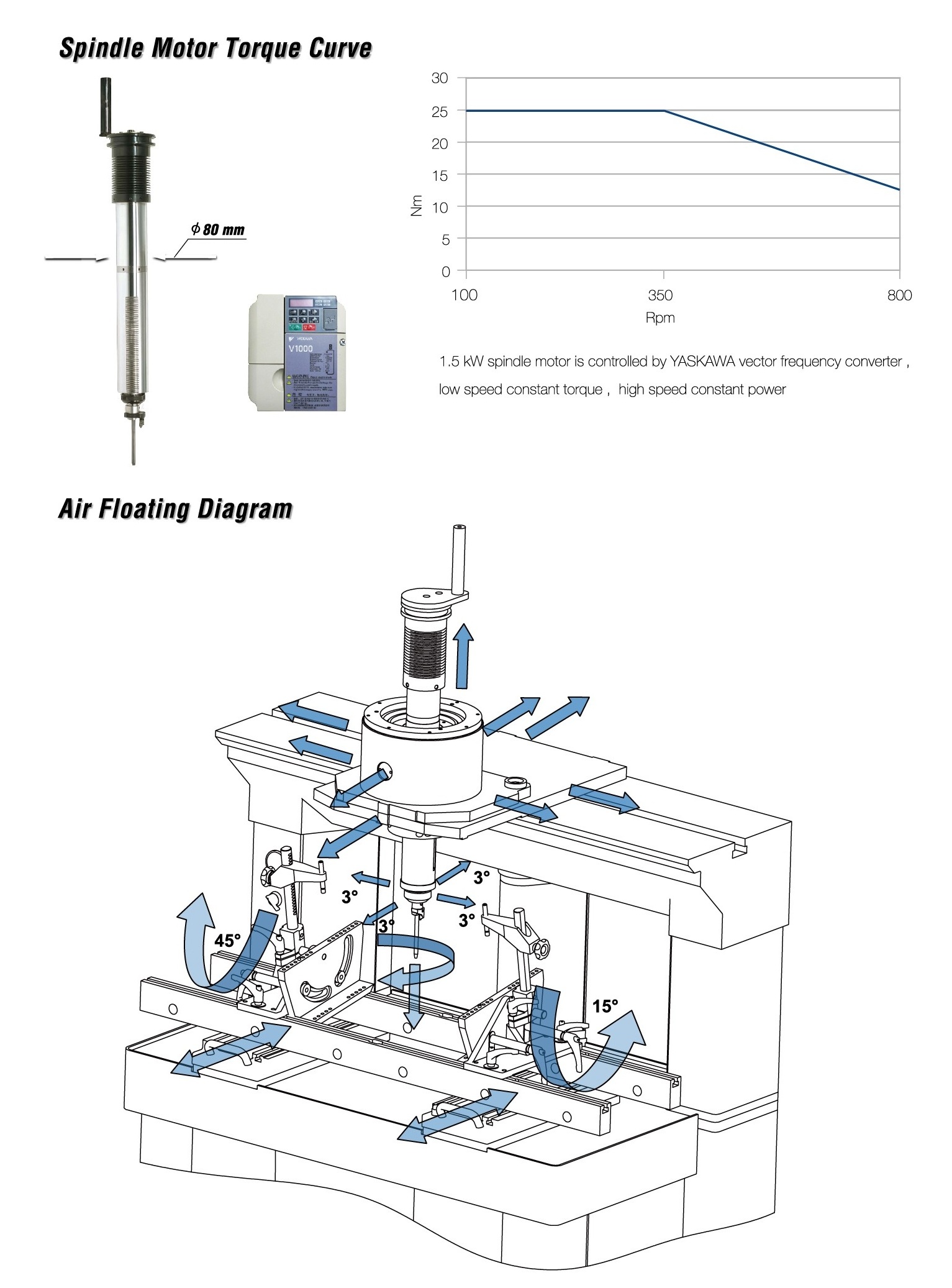

6) Fully integrated spindle motor: Infinitely variable speed 50 – 800 rpm, with sensorless Vector Flux Control in open loop. Extremely broad torque ratings from lowest RPM with constant torque spindle rotation. Digital RPM read-out for accurate speed setting.

7) Lightweight workhead: built-in spindle motor and triple air-float automatic centering system. Minimal workhead inertia and maximal floatation for unmatched centering sensitivity.

8) High-quality three color saturation painting.

1) Carbide pilot with shank dia. 9.52mm - 15pcs & Carbide cutting bit - 10pcs

2) Tool holder NWN5100F - 1pc 5300 - 1pc

3) Bit holder - 4 pcs

4) Dial gauge 1pc

5) Leveller for Valve Seat 1pc

6) Tool Setting Device 1pc

7) Vacuum Pad 1 set

8) T8x60 Torx Driver 1pc

9) Bit Sharpener 1 set

10) Ball point hex key set 9pcs

Note:

Above No. 9,10,11,12,15,17 are optional acc's at extra cost.