- Product Details

- {{item.text}}

Quick Details

-

Power:

-

100KW

-

Weight:

-

1000 KG

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Fuerstar

-

Voltage:

-

380V 3Phase 50HZ

-

Power:

-

100KW

-

Weight:

-

1000 KG

Products Description

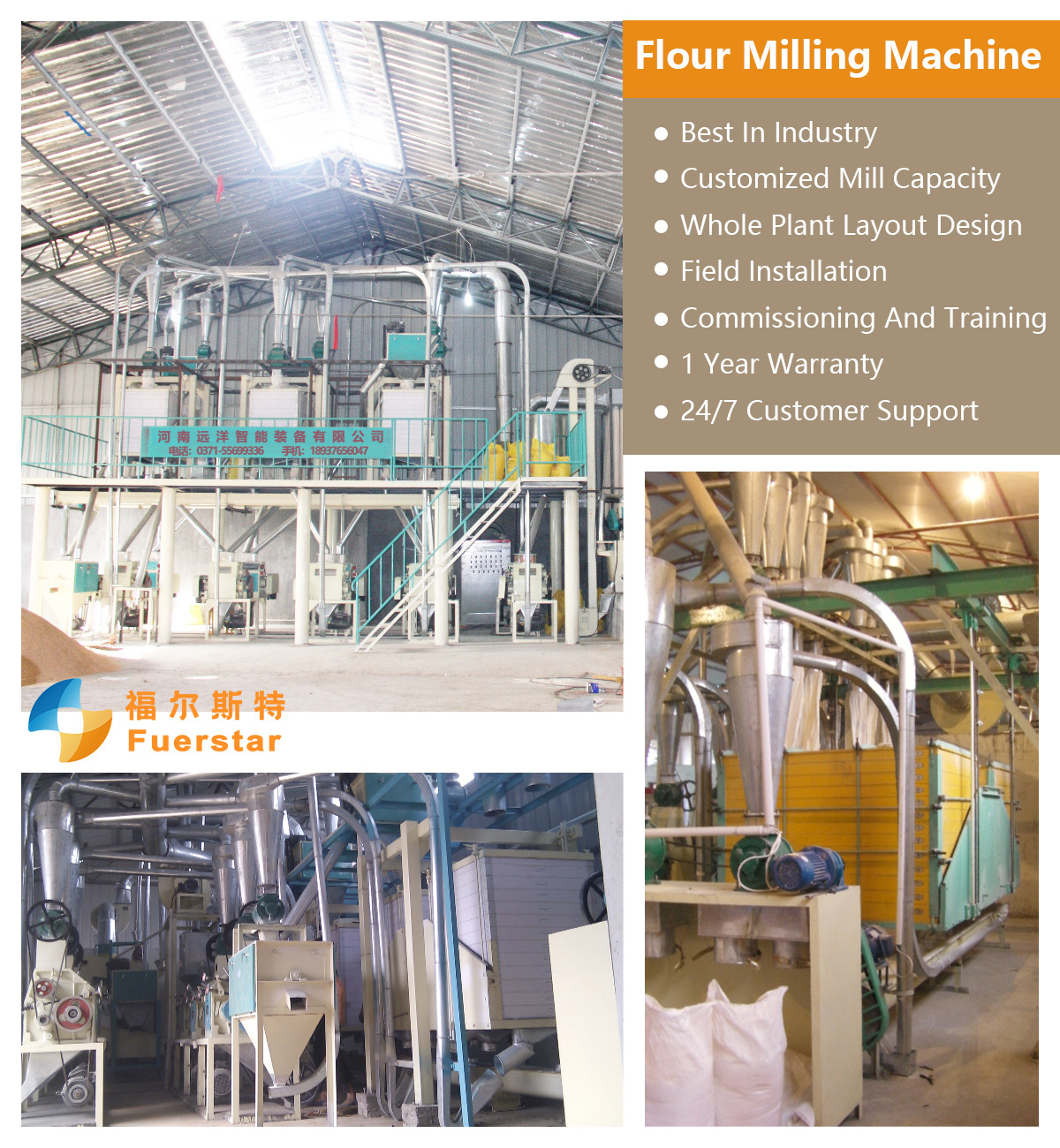

High-Quality, Cost-effective, and Efficient Complete

Wheat

Flour Mill Plant

Over 20 years, we have specialized in grain logistics, storage and processing technology for the grain and oil industry. Our expertise spans research and development, engineering consulting, engineering design, general contracting, engineering supervision, and manufacturing of mechanical and electrical equipment for handling staples like wheat, corn, rice, oil and feedstuff.

↘️Complete Wheat Flour Manufacturing Process

Flour milling is a complex process of separating the endosperm from the bran and germ of the wheat kernel and then grinding the endosperm into flour, which is sifted to obtain flours of different qualities.

\uD83D\uDD38 For manufacturing wheat flour, the main manufacturing process steps includes:

cleaning→watering→grinding→sieving grading→powdering→packaging, etc. (The specific process needs to be customized according to the actual needs of customers)

\uD83D\uDD38 For manufacturing wheat flour, the main manufacturing process steps includes:

cleaning→watering→grinding→sieving grading→powdering→packaging, etc. (The specific process needs to be customized according to the actual needs of customers)

\uD83D\uDD38

The

wheat

processing line includes four main sections:

Wheat is cleaned before milling, and according to the different characteristics of the impurities, the corresponding cleaning equipment (such as plane rotary screen, stone remover, magnetic separator) is utilized to remove various impurities. Then thewheat is moisture adjusted, which is favorable to the later peeling as well as crushing.

Next, the wheat is fed into the milling system, and after a series of grinding by the hulling mill, dregs mill and core mill, and

separation of pure flour grains, bran-containing flour grains and bran flakes by the clearing system, the final flour that meets the standard is extracted and sent for packaging.

Next, the wheat is fed into the milling system, and after a series of grinding by the hulling mill, dregs mill and core mill, and

separation of pure flour grains, bran-containing flour grains and bran flakes by the clearing system, the final flour that meets the standard is extracted and sent for packaging.

Main Features

1. Factory direct sale, 100% factory price.

2. High product quality, high yield and low power consumption

3. The grinding system adopts the method of "light grinding and fine scraping" to make coarse grain and coarse powder with good quality and to ensure the integrity of bran as far as possible.

3. The grinding system adopts the method of "light grinding and fine scraping" to make coarse grain and coarse powder with good quality and to ensure the integrity of bran as far as possible.

4. Well designed pneumatic conveying pipelines reduce power consumption

5. The production line can be configured to produce different purpose flours according to customers’ requirements.

5. The production line can be configured to produce different purpose flours according to customers’ requirements.

Hot Searches